A grassland fire truck that can quickly lay and retract the isolation belt

A technology of isolation belt and fire truck, applied in the field of fire protection and grassland fire protection, can solve the problems of slow extinguishing efficiency and low extinguishing speed, and achieve the effect of increasing the laying length, increasing the laying speed, and not easy to shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

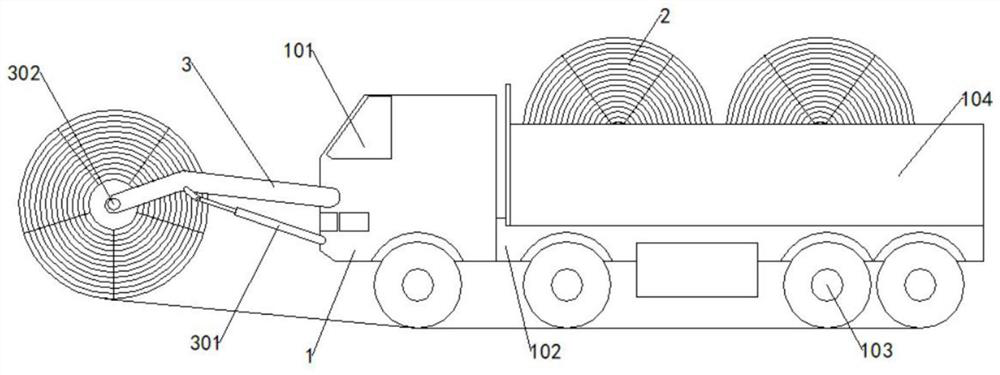

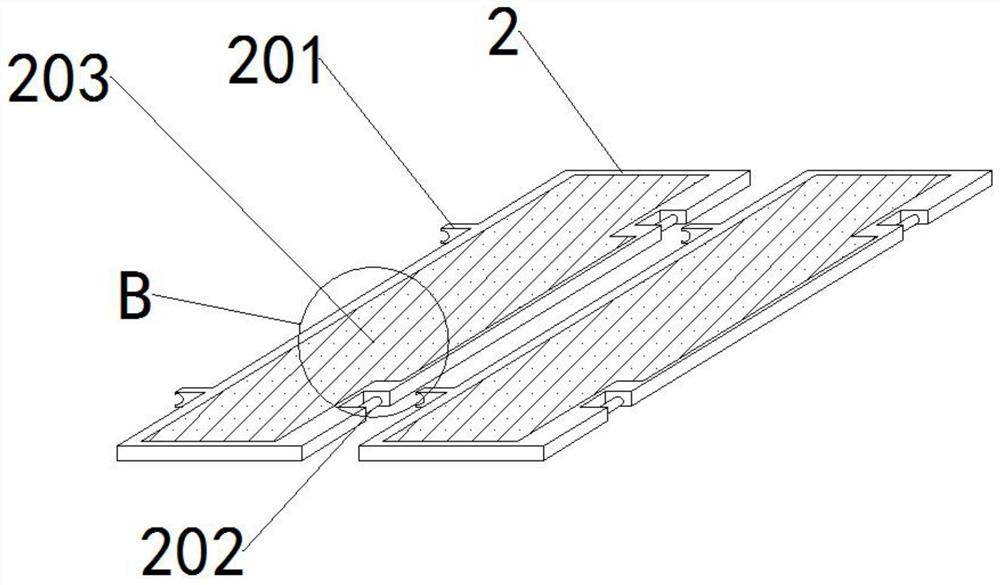

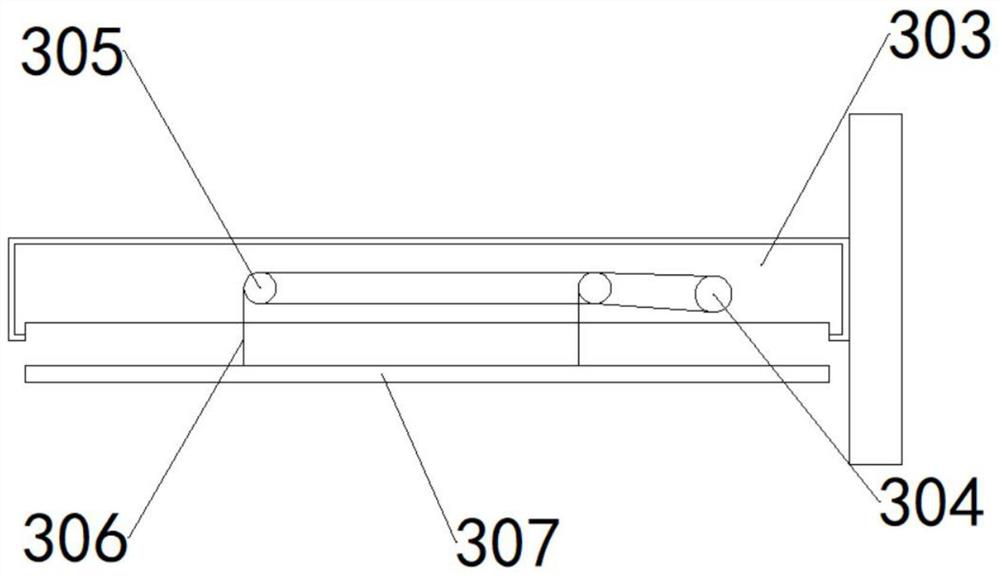

[0031] see Figures 1 to 10, in the embodiment of the present invention, a grassland fire truck capable of quickly laying and retracting the isolation belt includes a carrier 1, a cab 101, a platform 1011, a main beam 102, wheels 103, a storage bucket 104, an air strut 1041, Motor 105, turntable 106, fetching arm 107, hydraulic rod 1071, hydraulic rod 2 1072, partition 2, occlusal teeth 201, clamping cylinder 202, groove 203, main support arm 3, hydraulic rod 3 301, motor 2 302 , roller 303, motor 304, roller 305, steel wire 306, clamping cylinder two 307, roller two 4, hydraulic rod four 401 and push plate 402, the left side of carrier 1 is fixedly connected with cab 101, and the rear side surface of cab 101 is fixed The cab 101 is connected, the right side of the carrier 1 is fixedly connected with the main beam 102, the bottom of the carrier 1 is connected with wheels 103 for rotation, the top surface of the main beam 102 is fixedly connected with the storage bucket 104, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com