A kind of in-situ self-assembled nano flower-like cobalt disulfide/rgo composite material and its preparation method and application

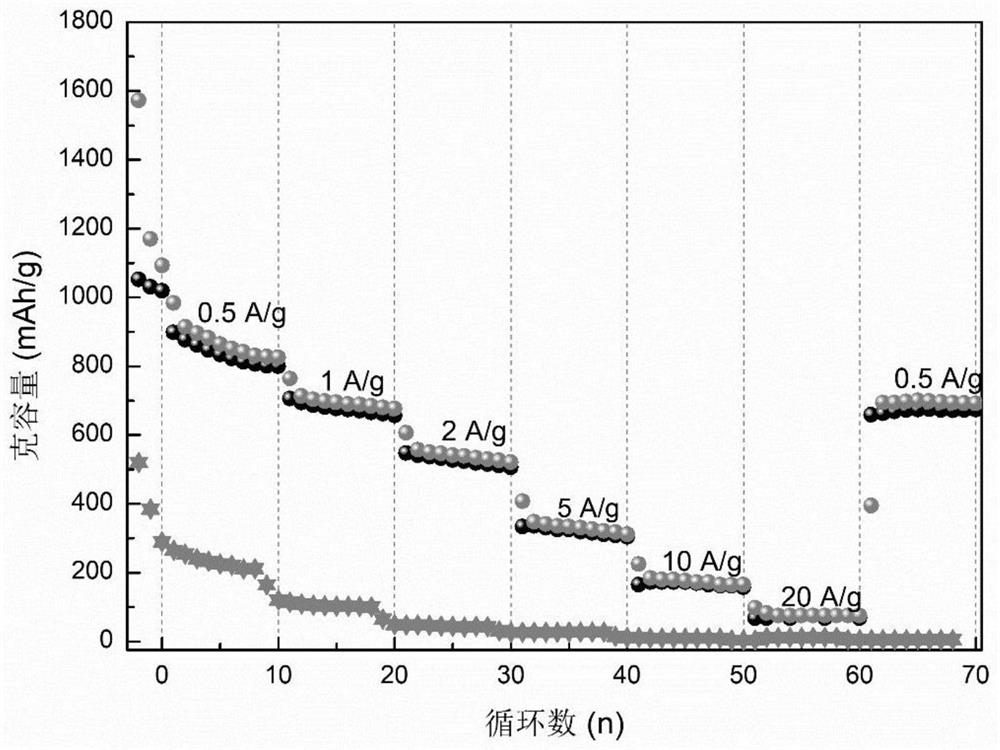

A technology of cobalt disulfide and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of not fully displaying the value, achieve excellent rate and cycle performance, and excellent Effects of charge-discharge cycle performance, rate performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Mix 5mmol CoSO 4 ·7H 2 O and 10mmol NaS were dissolved in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0035]2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0036] 3. Weigh the aqueous solution containing 50 mg GO and add it to the C solution in step 2, stir for 30 minutes, and ultrasonically disperse for 10 minutes to obtain the GO mixed solution D;

[0037] 4. Pour the solution D described in step 3 into a 100mL stainless steel reaction kettle, then put it into a blast drying oven, keep it warm at 150°C for 36h, and then carry out suction filtration after cooling in the furnace to obtain solid D;

[0038] 5. After the solid D described in step 4 is placed in a freeze drying oven for drying, the in situ self-assembled nano flower-like cobalt disulfide / rGO composite material is obtained.

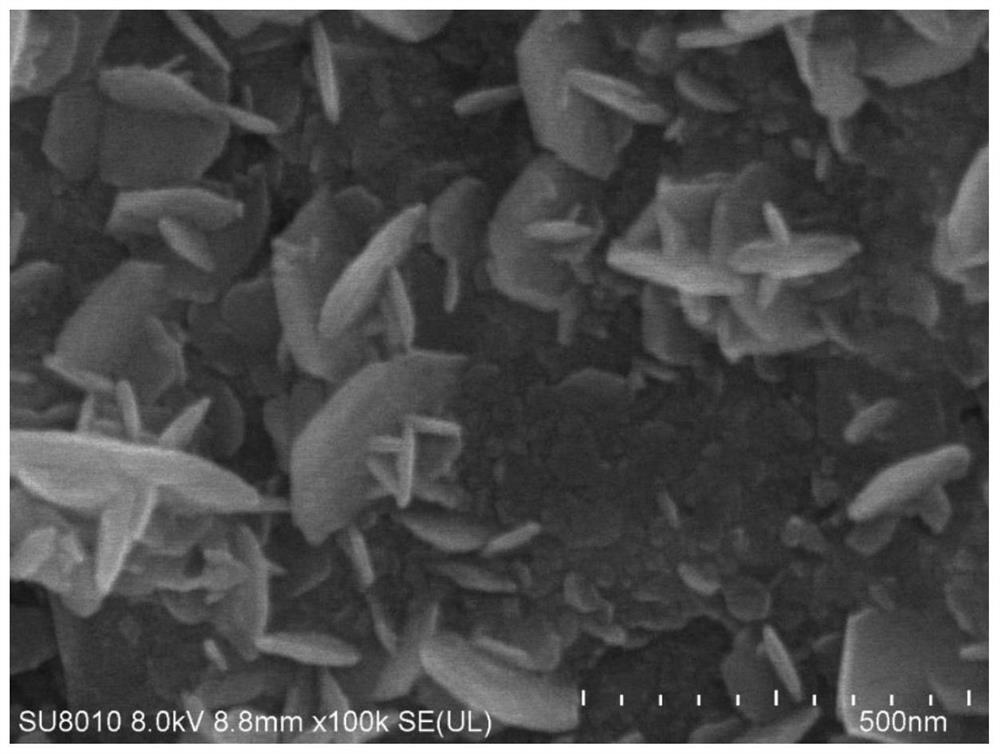

[0039] figure 1 It is a sca...

Embodiment 2

[0041] 1. Add 3mmol CoCl 2 ·6H 2 0 and 3mmol TAA (thioacetamide) were dissolved in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0042] 2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0043] 3. Weigh the aqueous solution containing 30mg GO and add it to the C solution in step 2, stir for 30 minutes, and ultrasonically disperse for 10 minutes to obtain the GO mixed solution D;

[0044] 4. Pour the solution D described in step 3 into a 100mL stainless steel reaction kettle, then put it into a blast drying oven, keep it warm at 150°C for 36h, and then carry out suction filtration after cooling in the furnace to obtain solid D;

[0045] 5. After the solid D described in step 4 is placed in a freeze drying oven for drying, the in situ self-assembled nano flower-like cobalt disulfide / rGO composite material is obtained.

Embodiment 3

[0047] 1. Add 4mmol CoCl 2 ·6H 2 0 and 4mmol L-cysteine were dissolved in 40mL deionized water respectively to obtain pink A solution and transparent B solution;

[0048] 2. Slowly add the A solution described in step 1 into the B solution and mix evenly, then fully stir for 30 minutes to obtain a light red C solution;

[0049] 3. Weigh the aqueous solution containing 40 mg GO and add it to the C solution in step 2, stir for 30 minutes, and ultrasonically disperse for 10 minutes to obtain the GO mixed solution D;

[0050] 4. Pour the solution D described in step 3 into a 100mL stainless steel reaction kettle, then put it into a blast drying oven, keep it warm at 150°C for 36h, and then carry out suction filtration after cooling in the furnace to obtain solid D;

[0051] 5. After the solid D described in step 4 is placed in a freeze drying oven for drying, the in situ self-assembled nano flower-like cobalt disulfide / rGO composite material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com