Electric hoist test power-enhanced weight system and using method thereof

An electric hoist and weight technology, which is applied in the field of electric hoist test booster weight system, can solve the problems of many weight combinations, high requirements for test benches and test sites, time-consuming and laborious weight matching, etc., to achieve lifting matching and installation Time, reduced weight handling work, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

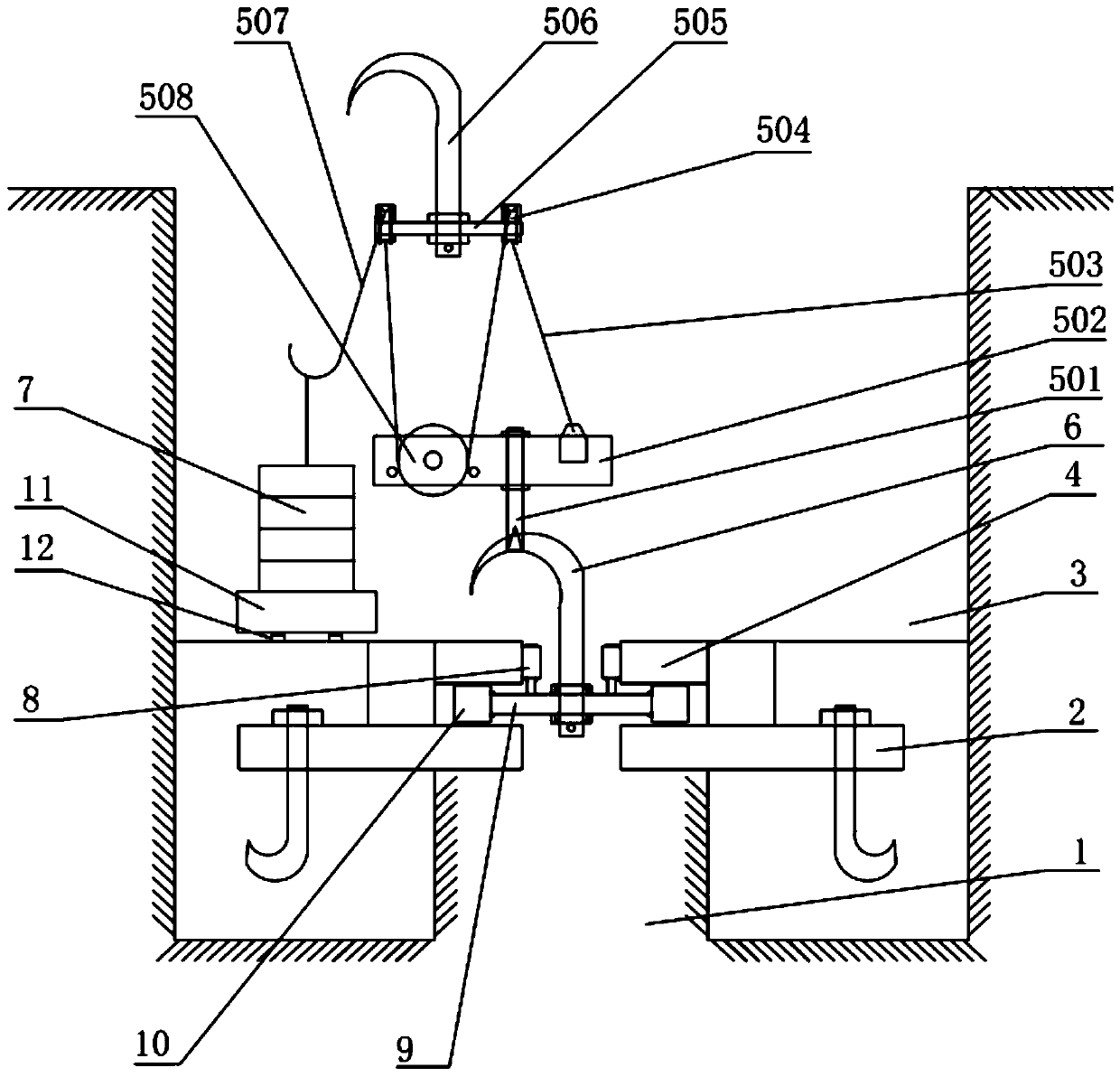

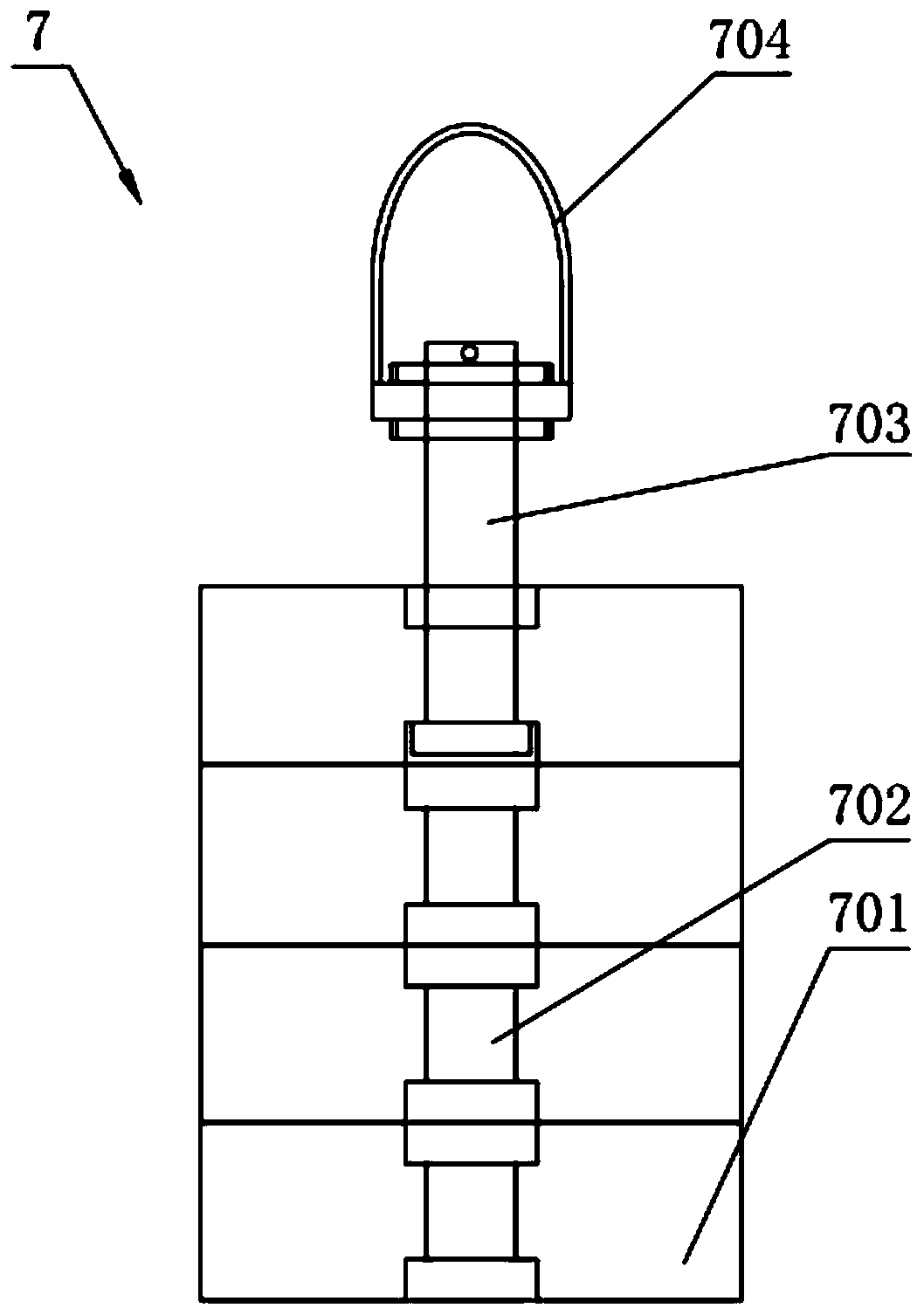

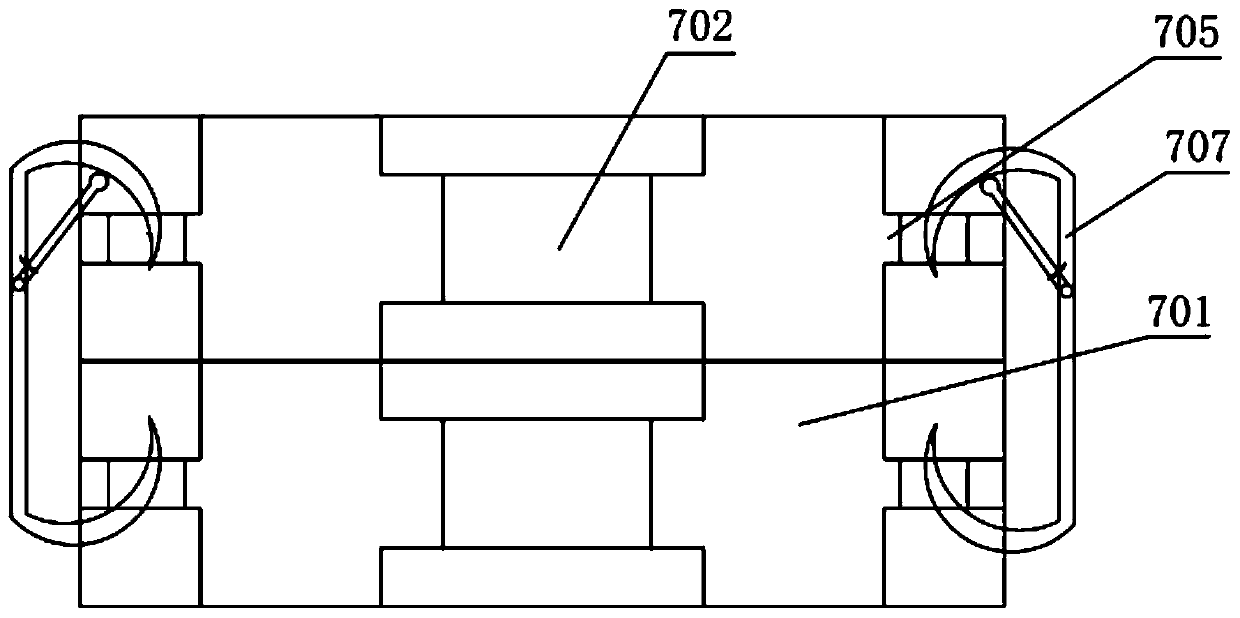

[0053] Such as figure 1 As shown, the electric hoist test power-increasing weight system of this embodiment includes a pit 3, an anchoring device is installed at the bottom, and an inverted ground anchor hook 6 protrudes upward from the top of the anchoring device; it also includes a power-increasing device, The bottom of the booster device is provided with a lower hook 501 connected to the ground anchor hook 6, and the top of the booster device protrudes upwards with an inverted upper hook 506, and a weight hook 507 is installed downward through the side of the steel wire rope 503 in the booster device. The weight hook 507 is hung with a weight assembly 7; the steel wire rope 503 connected with the weight hook 507 passes through a plurality of pulleys in turn to realize force increase; during the test, the anchoring device, the force incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com