Torque shunting speed reducer and application method, detection and control system thereof

A control system and reducer technology, applied in linear/angular velocity measurement, speed/acceleration/impact measurement, mechanical equipment, etc. Reliability and stability, increased service life, avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0049] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

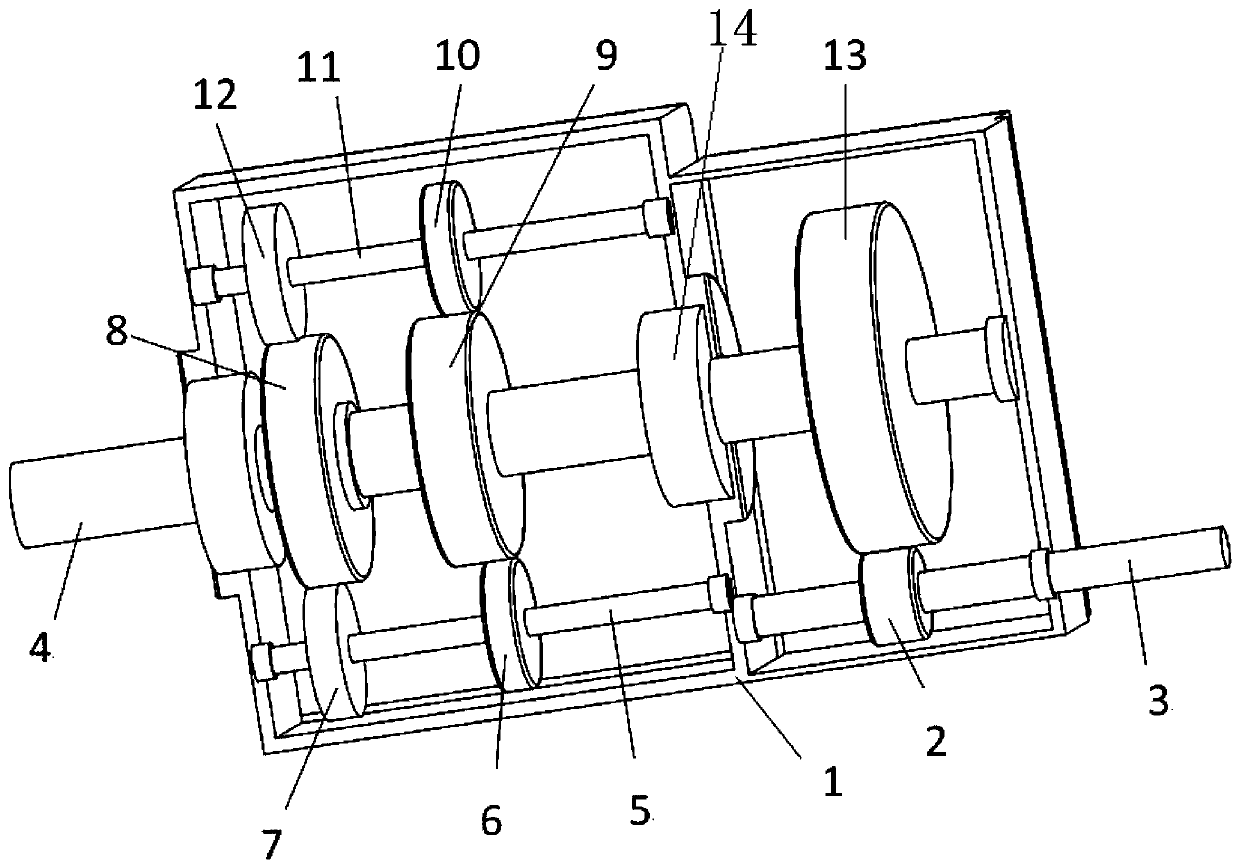

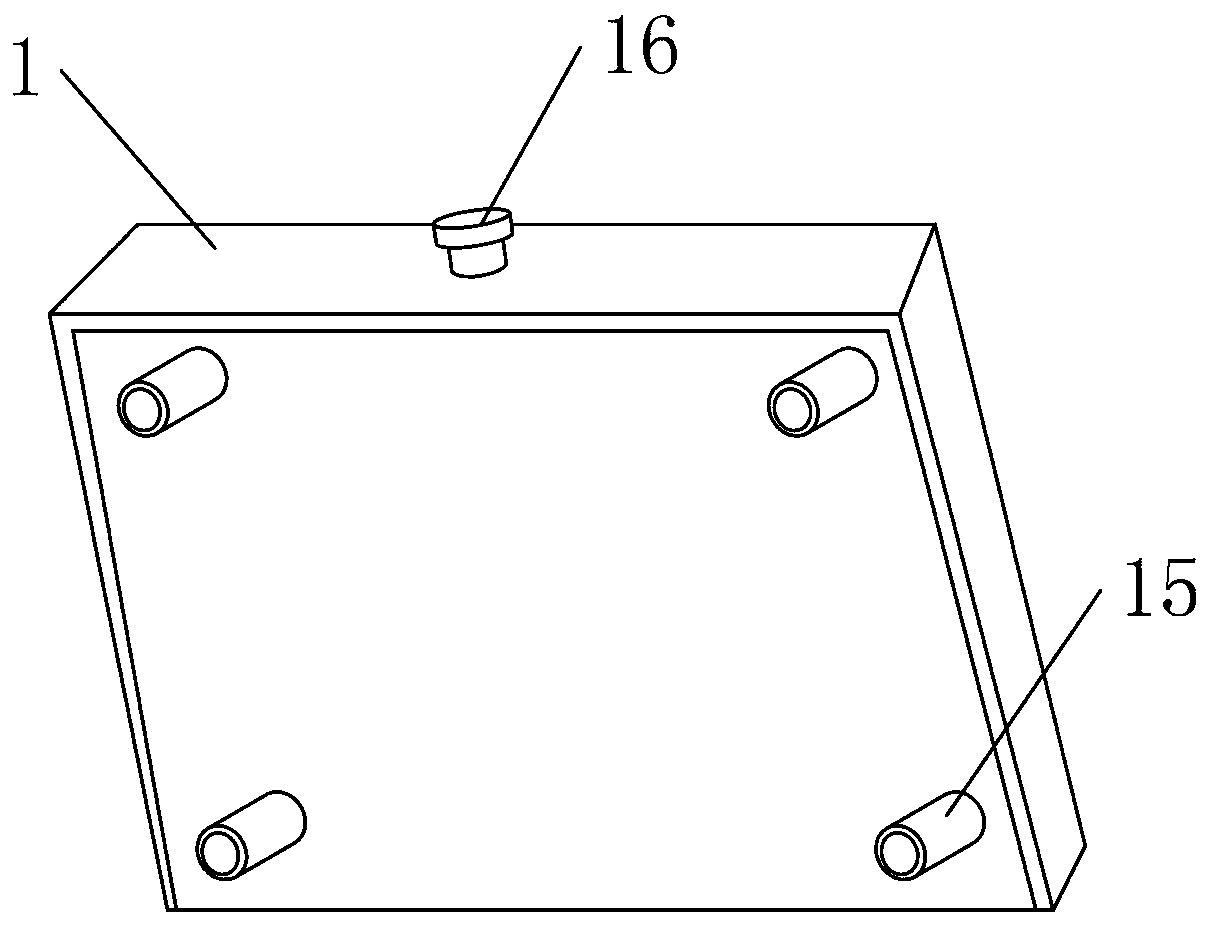

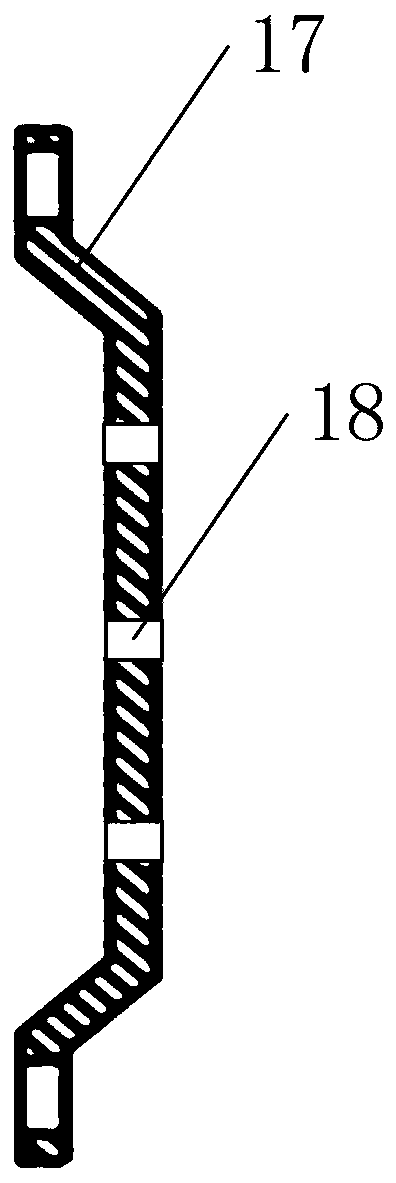

[0050] Such as Figure 1 to Figure 3 As shown, the torque split reducer provided by the embodiment of the present invention includes: reducer housing 1, input shaft spur gear 2, input shaft 3, output shaft 4, first split shaft 5, first split shaft first spur gear 6 , the second spur gear of the first diverter shaft 7, the first spur gear of the output shaft 8, the second spur gear of the output shaft 9, the first spur gear of the second diverter shaft 10, the second diverter shaft 11, the second straight gear of the second diverter shaft Gear 12, the third spur gear 13 of the output shaft, bearing 14, threaded fixing post 15, grease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com