Pile bearing type half-sphere breakwater structure and construction method

A semi-circular body and breakwater technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve the problem of inconvenient semi-circular body structure replacement, and achieve the effect of easy replacement, simple operation, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

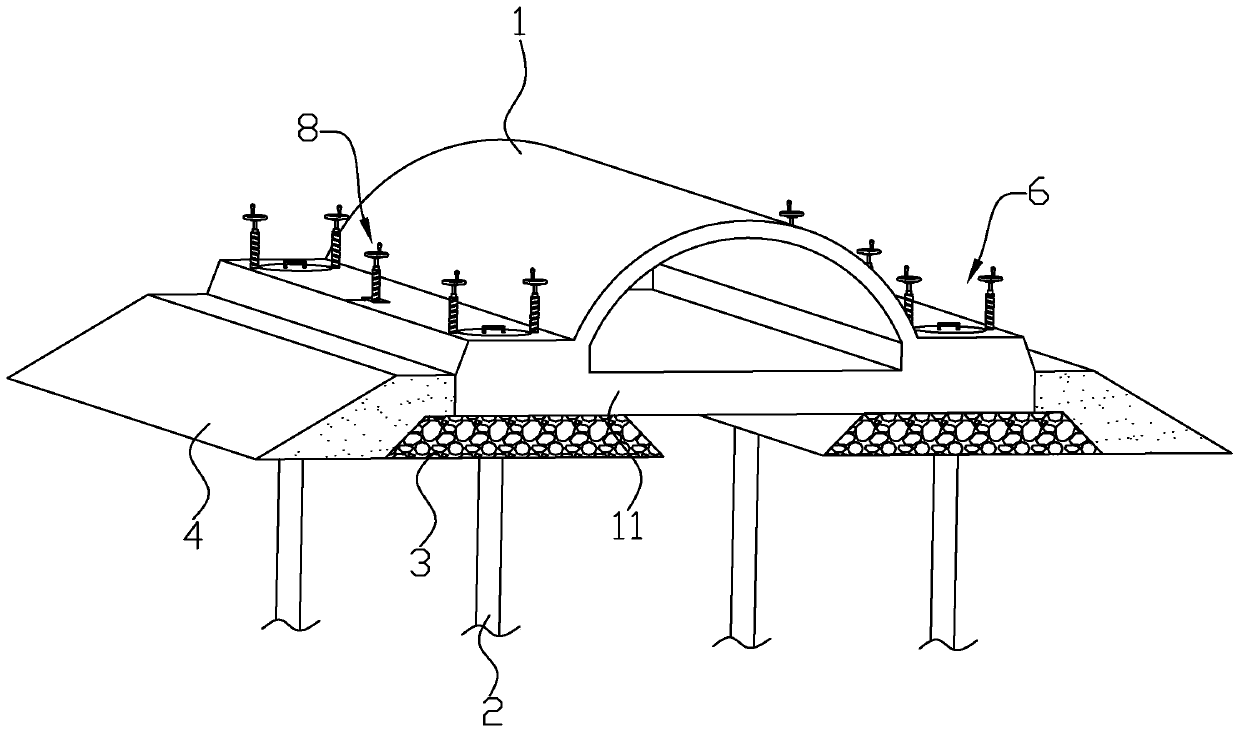

[0037] Embodiment: a pile-supported semicircular body breakwater structure, such as figure 1 As shown, it includes a semicircular body structure 1, foundation piles 2, crushed stone cushion 3 and bottom protection blocks 4, and the semicircular body structure 1 includes a base 11, on which there are multiple groups corresponding to the foundation piles 2 for one-to-one A fixing device 5 for fixing the foundation pile 2.

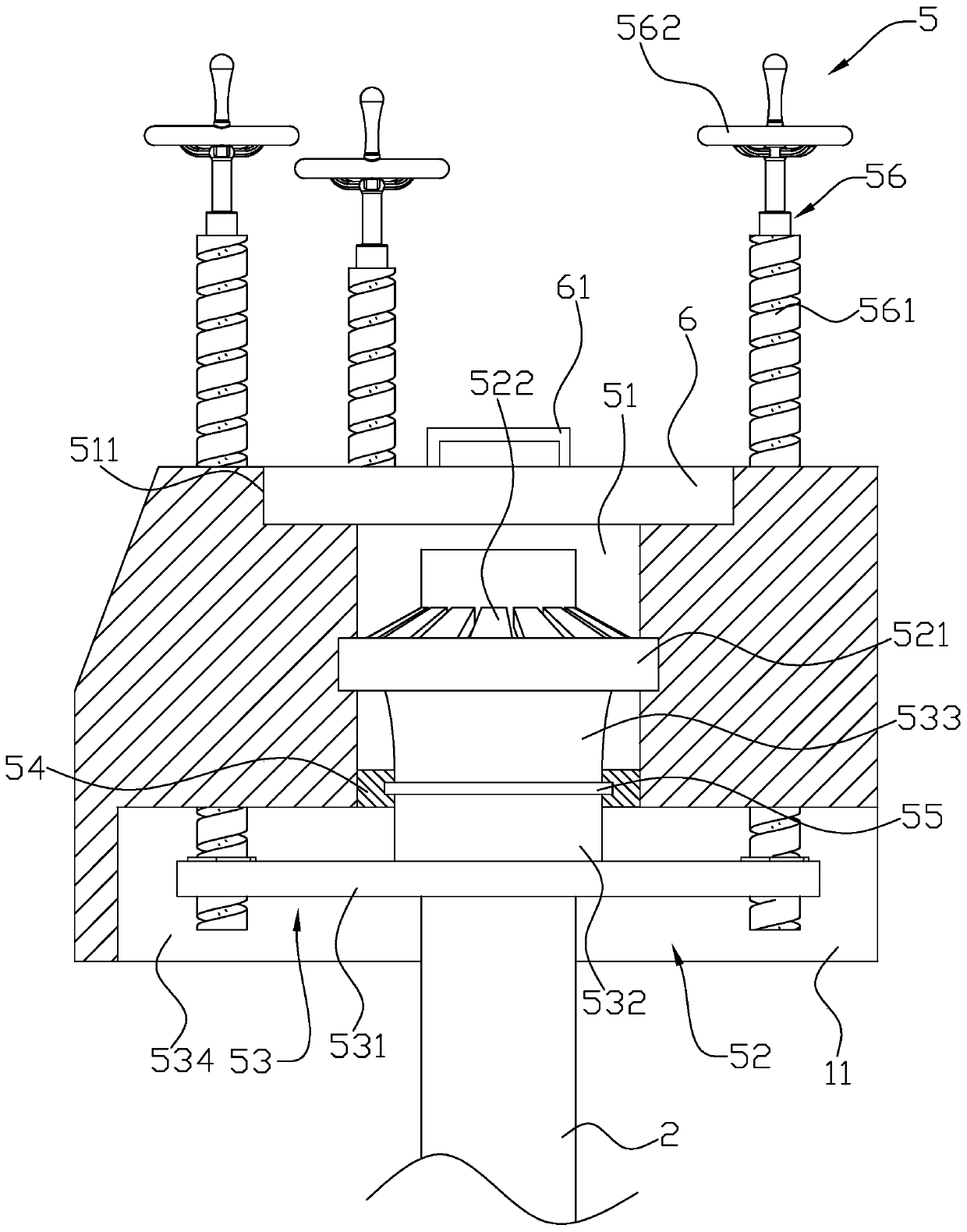

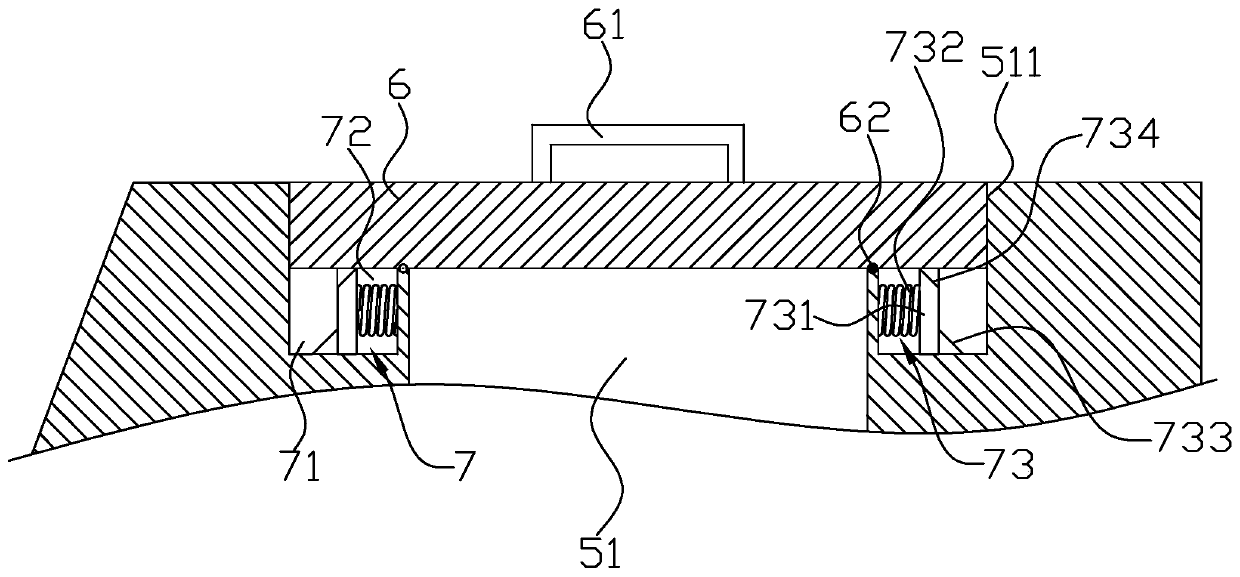

[0038] Such as figure 1 and figure 2 As shown, each set of fixing devices 5 includes an installation hole 51 opened on the base 11 and for the foundation pile 2 to pass through, and a first fixing mechanism 52 prefabricated in the installation hole 51 for fixing the foundation pile 2; the first fixing mechanism 52 includes The ring block 521 prefabricated on the inner wall of the installation hole 51, the plurality of elastic plates 522 fixed to the inner peripheral surface of the ring block 521 along the circumferential direction of the ring block 521 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com