A rapid repair device for road and bridge pavement

A fast and fast installation technology, which is applied in the direction of road repair, road, road, etc., can solve the problems of long construction period, many machines used, and low mechanical integration, and achieve the effect of improving repair quality and paving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

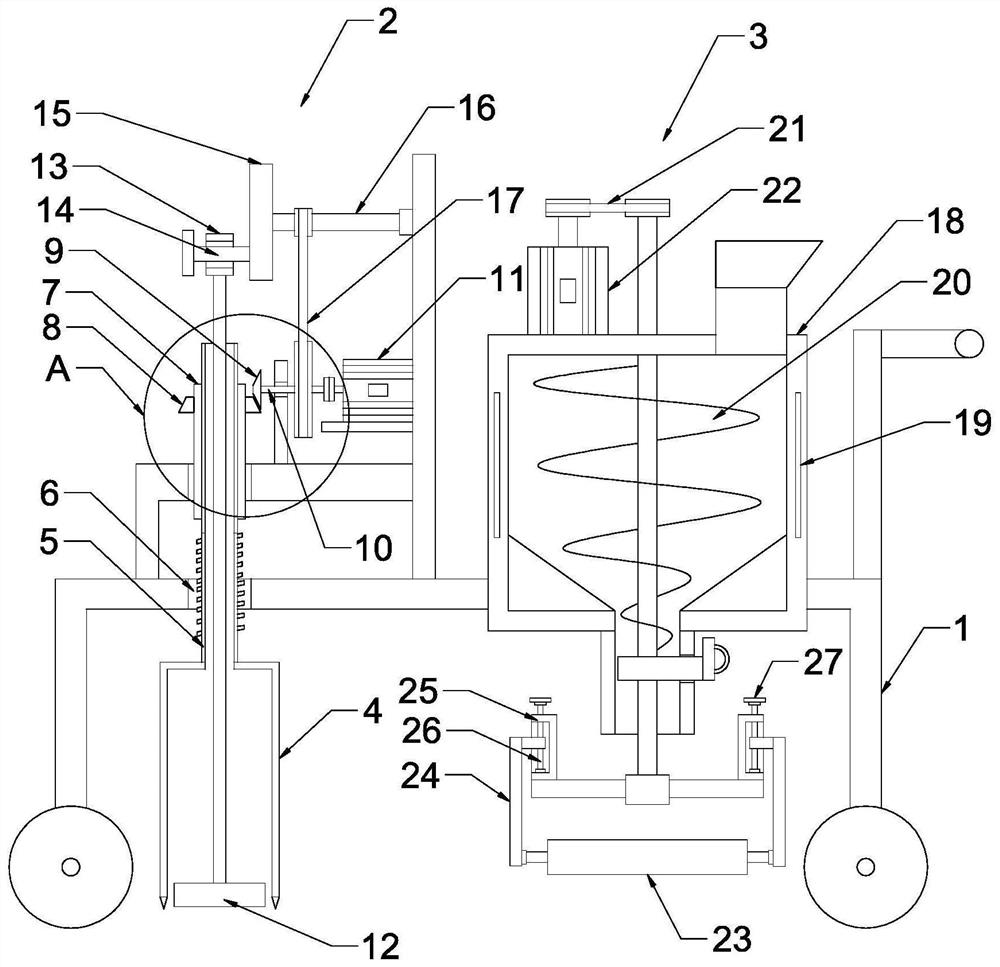

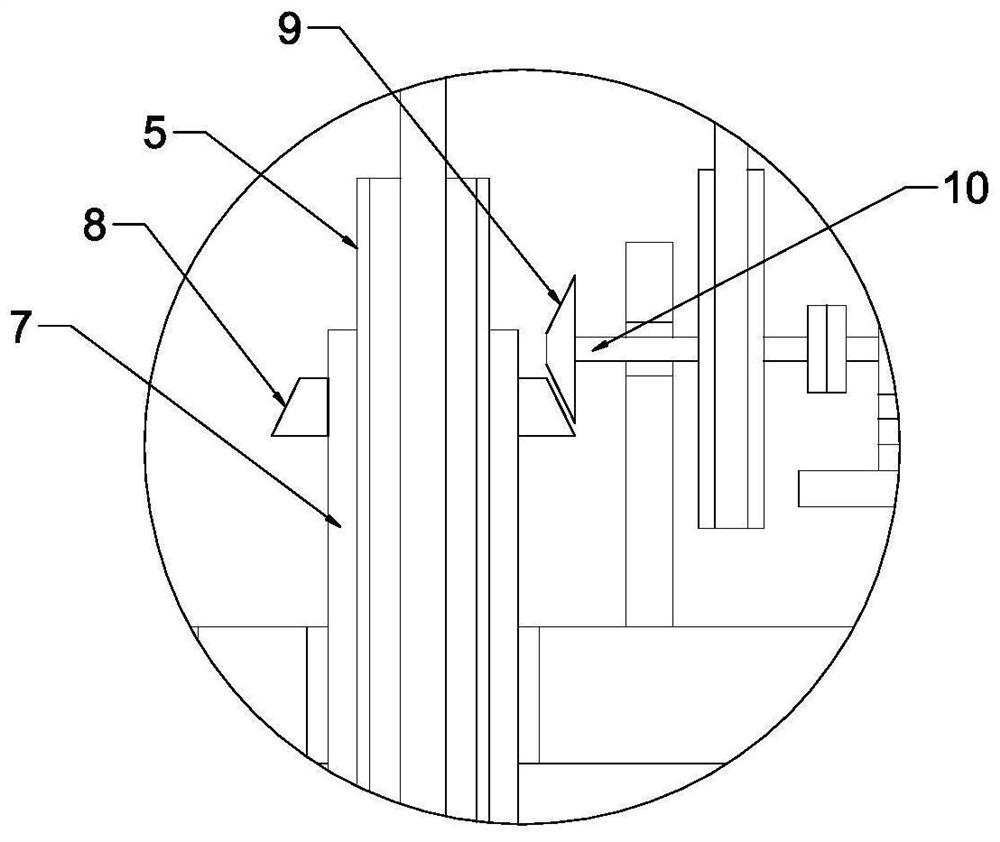

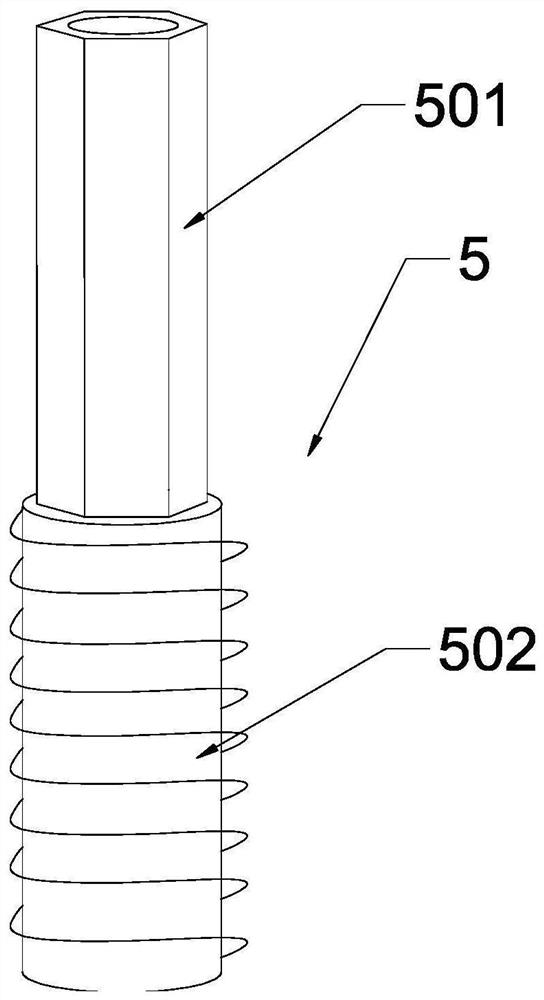

Embodiment 1

[0021] see Figure 1-4 , in an embodiment of the present invention, a road and bridge road surface rapid repair device includes a car body 1, a cleaning mechanism 2 and a paving mechanism 3; The cylinder 5 is a hollow cylindrical structure with upper and lower ends open. The special-shaped cylinder 5 includes a prism part 501 and a threaded part 502; the threaded part 502 runs through the vehicle body 1 and is threaded with a threaded cap 6, which is nested in the vehicle body. 1 and is fixedly connected with the vehicle body 1; the prism part 501 is provided with a prism sleeve 7, the prism sleeve 7 is a hollow sleeve provided with a prism cavity, and the prism sleeve 7 is rotatably connected with a mounting frame through a bearing sleeve, The mounting frame is fixedly connected with the car body 1; the prism sleeve 7 is socketed and fixed with a bevel gear ring 8, the bevel gear ring 8 is engaged with a driving bevel gear 9, and the driving bevel gear 9 is fixedly connected ...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that a compacting roller 23 is arranged below the heating and stirring tank 18, and the compacting roller 23 is rotatably connected with a lifting frame 24, and the lifting frame 24 is nested with a slide rail frame 25, and the lifting frame 24 A screw mandrel 26 runs through and is threadedly connected, and an adjustment handwheel 27 is fixedly connected to the upper end of the screw mandrel 26. By rotating the adjustment handwheel 27, the screw mandrel 26 is driven to rotate, and then the elevating frame 24 and the compacting roller 23 are driven to move up and down; The rail frame 25 is fixedly connected with the spiral stirring roller 20, and the spiral stirring roller 20 drives the compacting roller 23 to rotate to improve the compacting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com