Buried liquid quenching and spraying device

A spray device and spray port technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve problems such as large dispersion of deformation, uneven flow field, excessive deformation, etc., to ensure consistency and meet restrictions Requirements, the effect of deformation optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

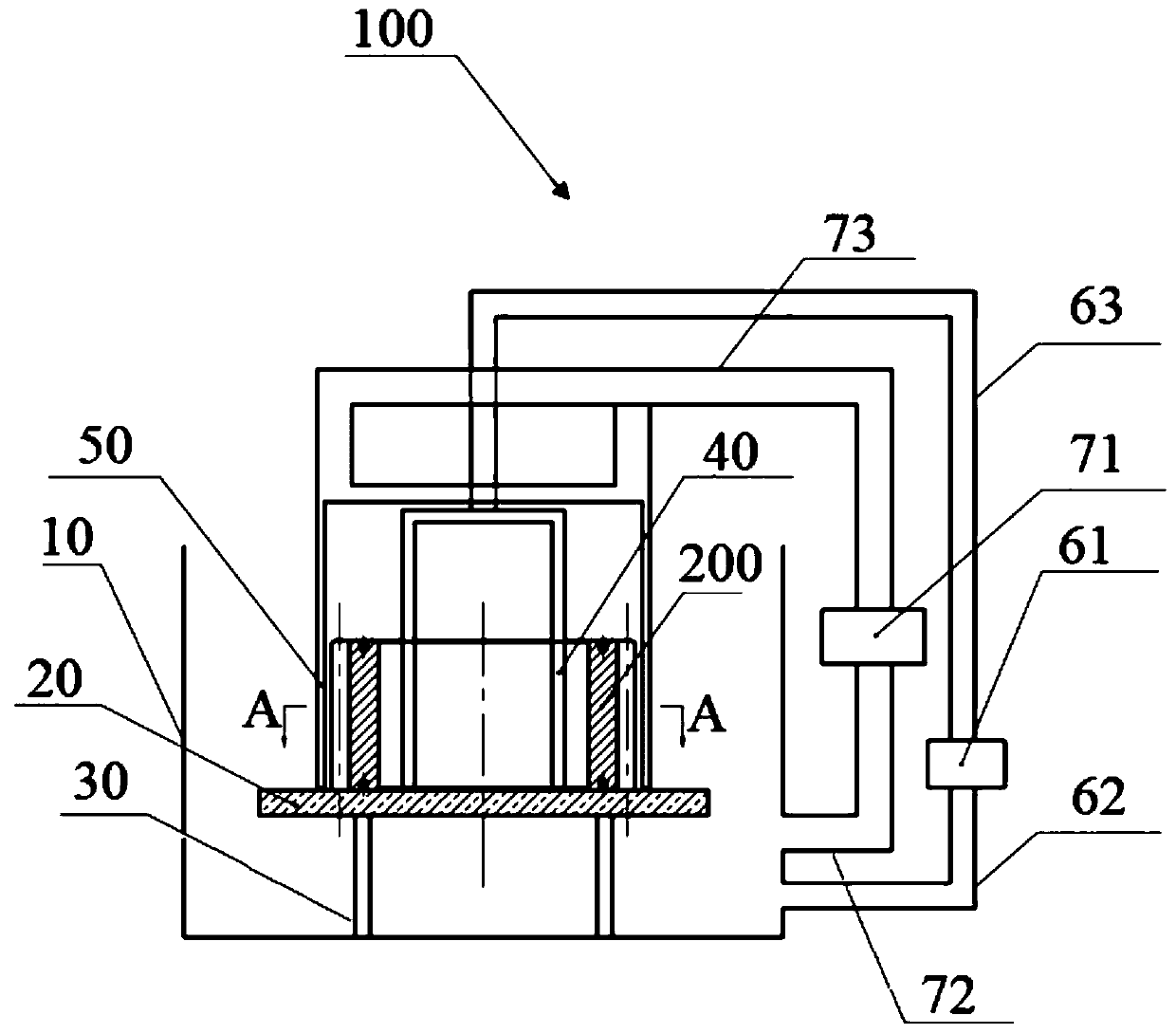

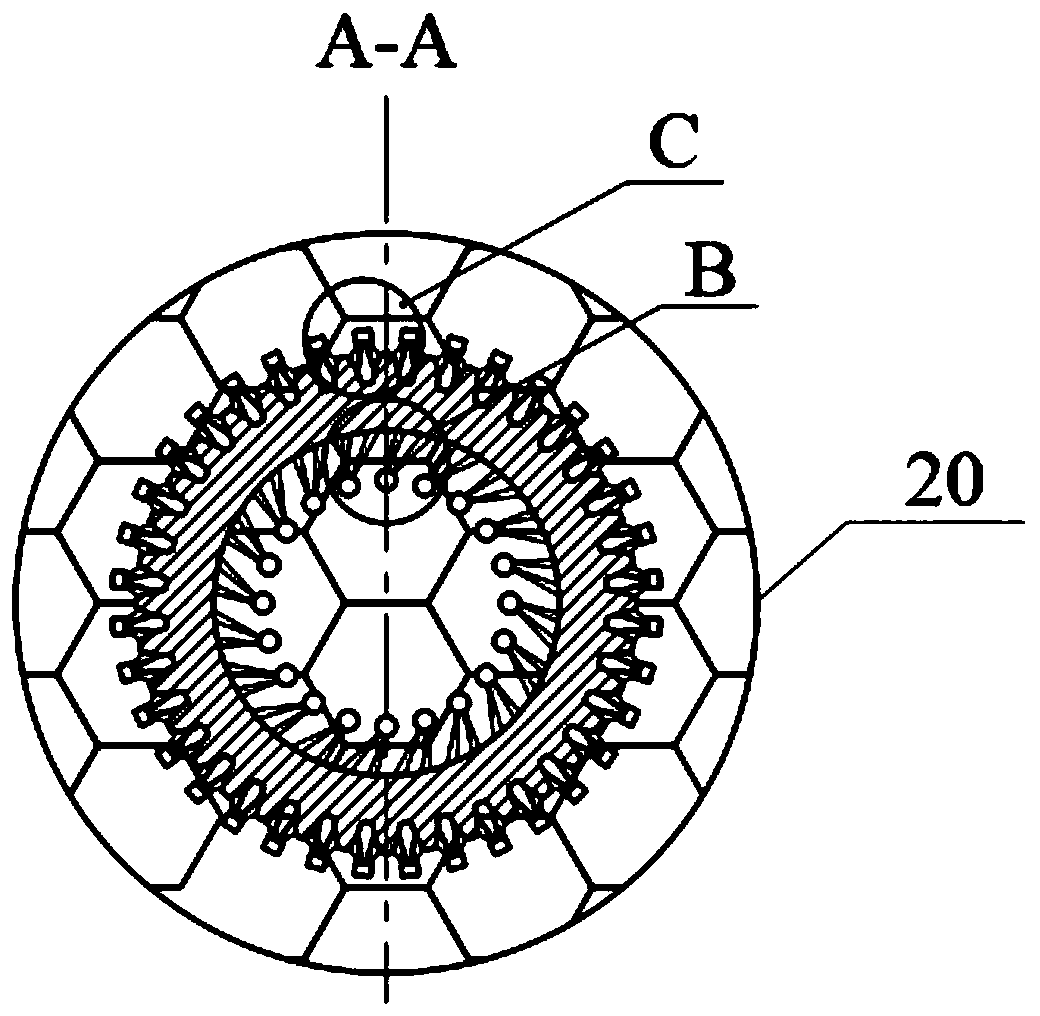

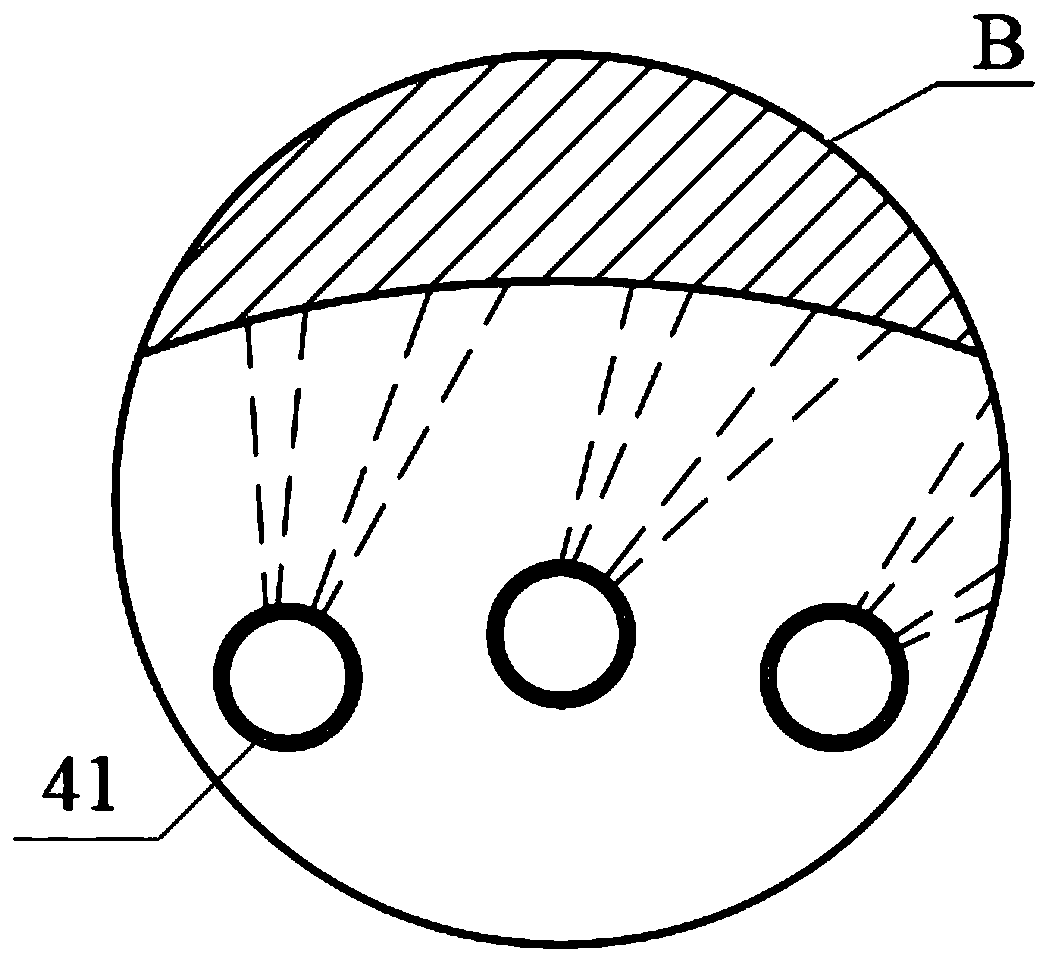

[0026] Such as Figure 1 to Figure 4 As shown, a buried liquid quenching spraying device 100 includes: an outer tank 10, a lifting platform 20, a lifting device 30, an inner spraying device 40, an outer spraying device 50, a first circulation device and a second circulation device.

[0027] The buried liquid quenching and spraying device 100 is used for quenching parts with inner holes, and is also called a buried liquid quenching and spraying device suitable for parts with inner holes. The buried liquid quenching and spraying device 100 can quench gears, and can be called a buried liquid quenching and spraying device suitable for gears.

[0028] The outer tank 10 is used to accommodate the quenching medium. The part 200 is placed in the outer tank 10 and immersed in the quenching medium.

[0029] The lifting platform 20 is used to carry p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com