Modified phenolic molding compound with high bending strength and preparation method of modified phenolic molding compound

A phenolic molding compound and flexural strength technology, applied in the field of phenolic plastics, can solve the problems of easy deformation of phenolic molding compound, reducing brittleness of phenolic molding compound, decrease in tensile strength and compressive deformation resistance of phenolic molding compound, etc. The effect of internal small molecule residues, improved fluidity, and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

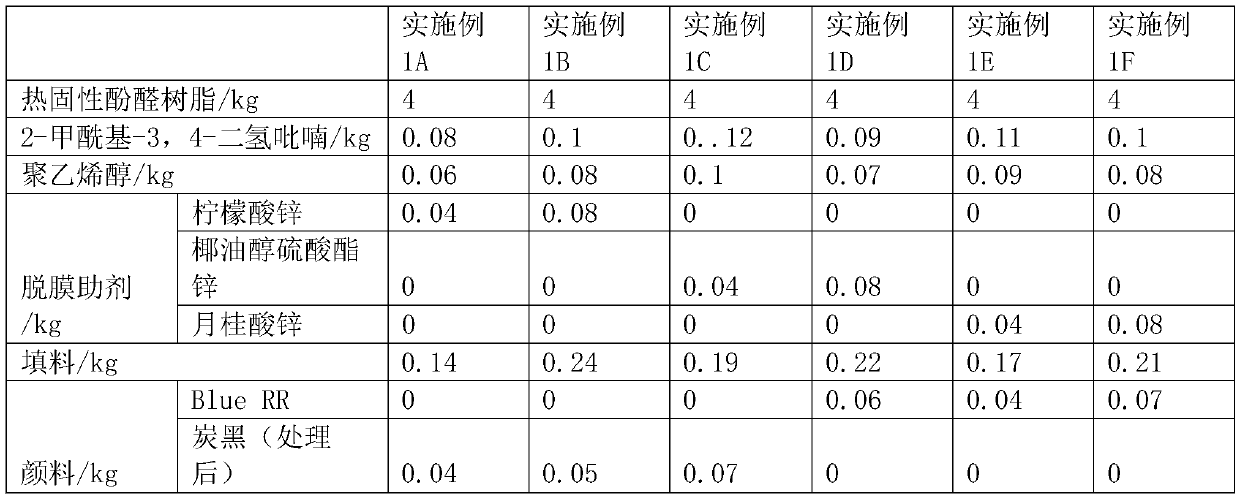

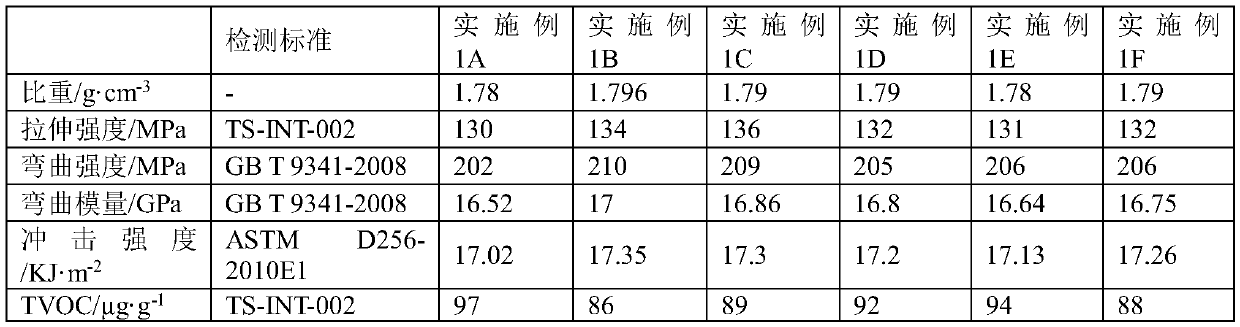

Embodiment 1

[0047] A modified phenolic molding compound with high bending strength, the modified phenolic molding compound includes the following raw materials in parts by mass:

[0048] 200 parts of thermosetting phenolic resin,

[0049] 4-6 parts of 2-formyl-3,4-dihydropyran,

[0050] 3-5 parts of polyvinyl alcohol,

[0051] Release aid 0.2-4 parts,

[0052] Filling 7-12 parts,

[0053] Pigment 2-3.5 parts,

[0054] Wherein the thermosetting phenolic resin is a liquid thermosetting phenolic resin.

[0055] The thermosetting phenolic resin can be commercially available or self-prepared, as follows:

[0056] Phenol and basic catalyst (NaOH or KOH) are added to the reactor at a mass ratio of 1:0.05, and then formaldehyde is added to the reactor at a molar ratio of phenol:formaldehyde=1:1.5 for reaction. The reaction temperature is 95-110°C and the reaction time is 1h , and then remove moisture and unreacted raw materials under normal pressure and then under reduced pressure to obtain...

Embodiment 2

[0088] A modified phenolic molding compound with high bending strength, based on the basis of Example 1B, the difference is that the release agent is commercially available stearic acid, calcium stearate, zinc stearate, magnesium stearate One of them, the part by mass of the release aid is 0.2-0.4 parts.

[0089] Example 2A Example 2B Example 2C Example 2D Release aid stearic acid Calcium stearate Zinc stearate Magnesium stearate

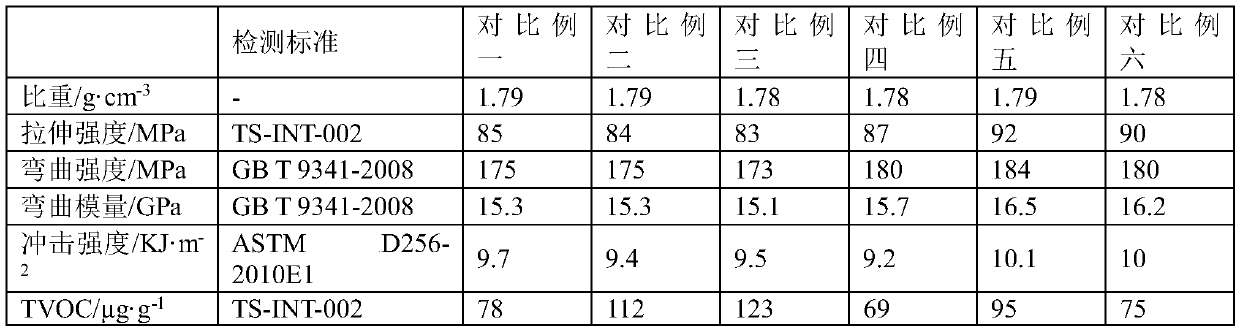

[0090] The test results of the sample obtained in Example 2 are as follows.

[0091] Testing Standard Example 2A Example 2B Example 2C Example 2D Specific gravity / g·cm -3

- 1.79 1.79 1.79 1.79 Tensile strength / MPa TS-INT-002 122 124 130 125 Bending strength / MPa GB T 9341-2008 192 197 198 196 Flexural modulus / GPa GB T 9341-2008 16.53 16.61 16.65 16.63 Impact strength / KJ m -2

ASTM D256-2010E1 16.6 16.8 17 16.9 TVOC / μg·g -1

TS-I...

Embodiment 3

[0095] A modified phenolic molding compound with high bending strength, based on the basis of Example 1B, the difference is that the filler is commercially available shell powder that has not been calcined or heated at high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com