Municipal sludge wall breaking and brickmaking method

A municipal sludge and sludge technology, which is applied in the direction of sludge treatment, oxidation treatment sludge, chemical instruments and methods, etc., can solve problems such as environmental pollution and dehydration difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

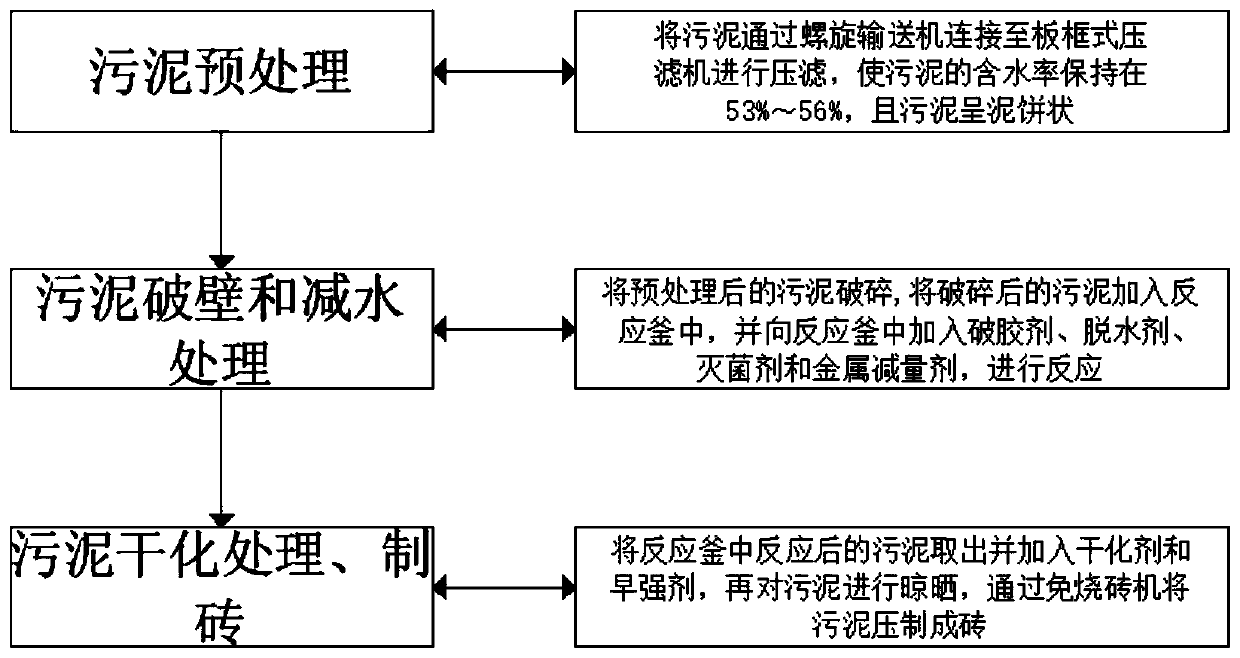

[0026] Such as figure 1 Shown, a kind of municipal sludge wall breaking and brick making method, concrete steps are as follows:

[0027] (1), sludge pretreatment;

[0028] (2), sludge wall breaking and water reduction treatment;

[0029] (3) Sludge drying treatment and brick making.

[0030] The sludge pretreatment method in step (1) is specifically as follows: the sludge is connected to a plate and frame filter press through a screw conveyor for pressure filtration, so that the moisture content of the sludge is kept at 53% to 56%, and the sludge is Mud cake.

[0031] In the step (2), the sludge wall breaking and water reduction treatment, the specific steps are as follows:

[0032] (2.1), the mud cake shape sludge obtained in step (1) is bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com