Large-scale truck tray-free automatic loader

A palletless, car loader technology, applied in conveyors, loading/unloading, mechanical conveyors, etc., can solve problems such as difficulty in automation, and achieve the effect of lowering the center of gravity, high control accuracy, and improving automatic shipping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

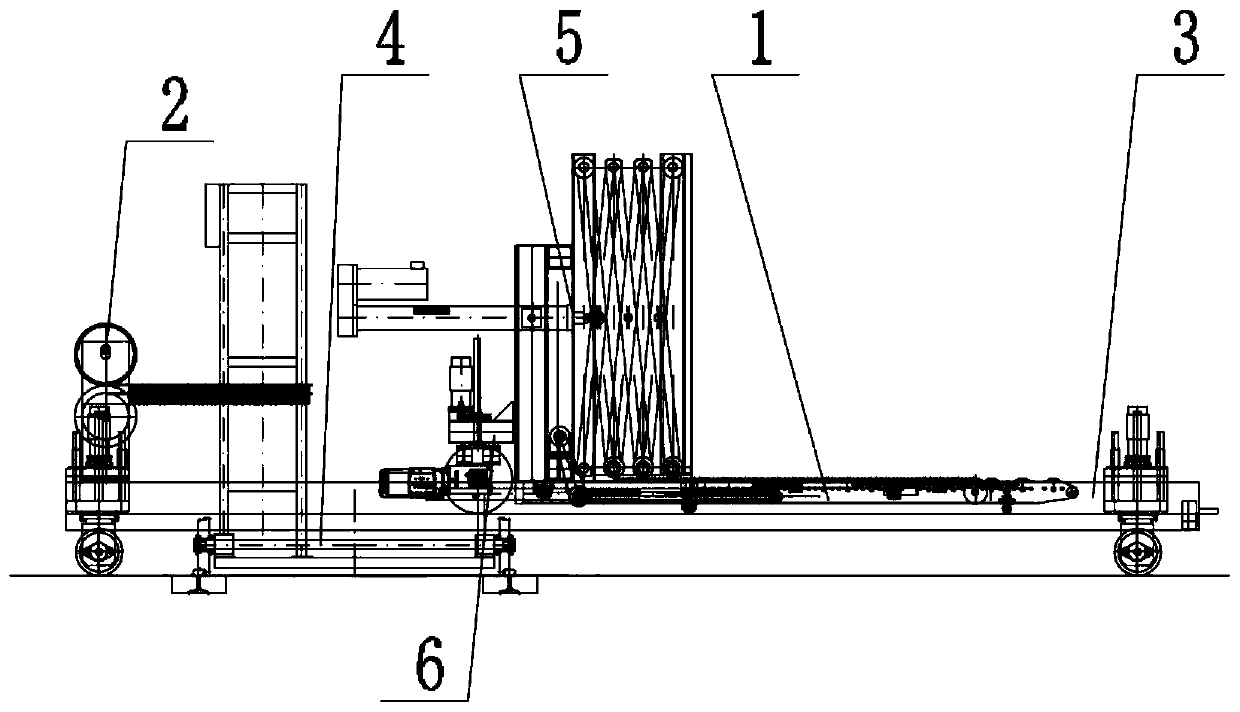

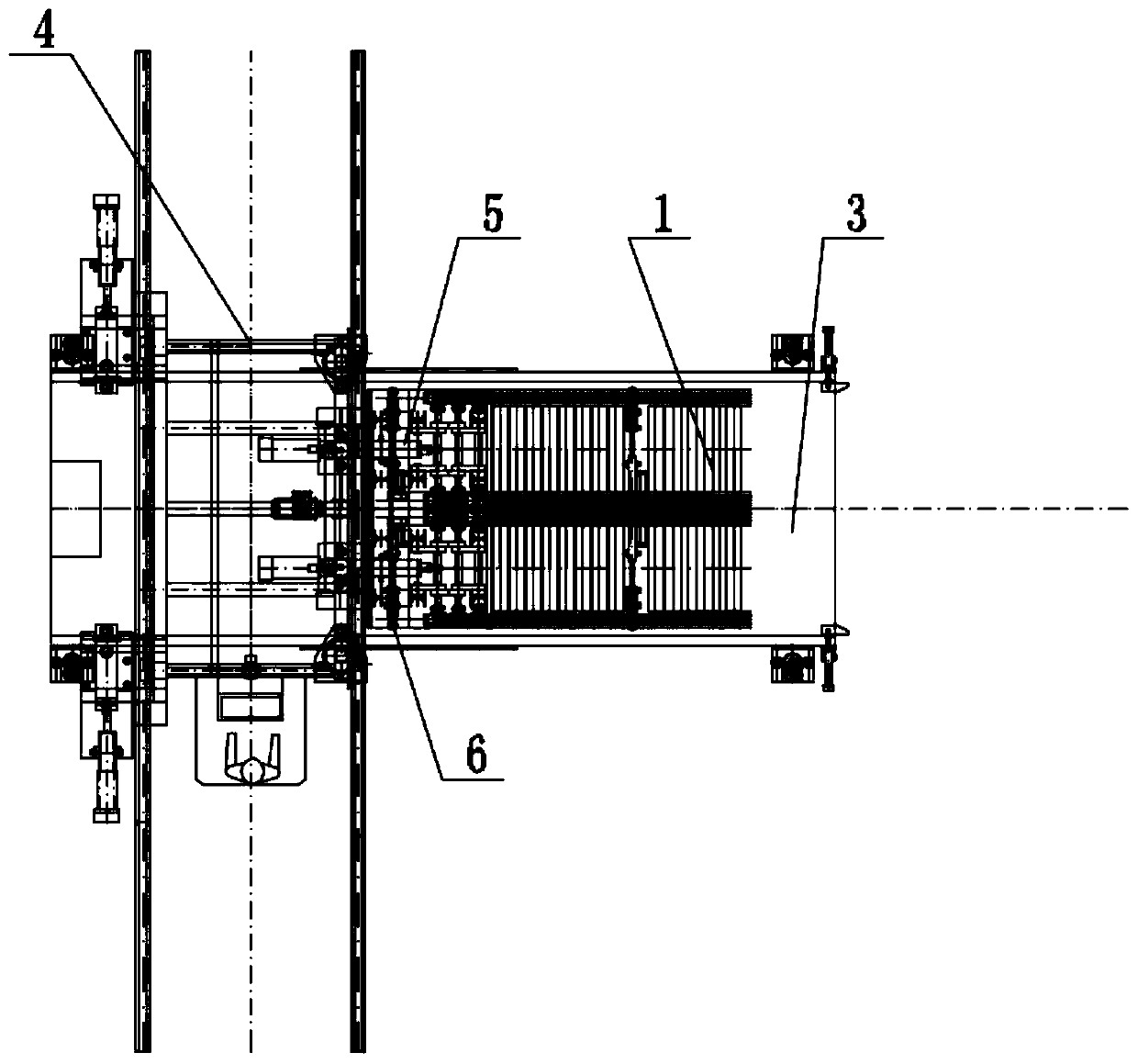

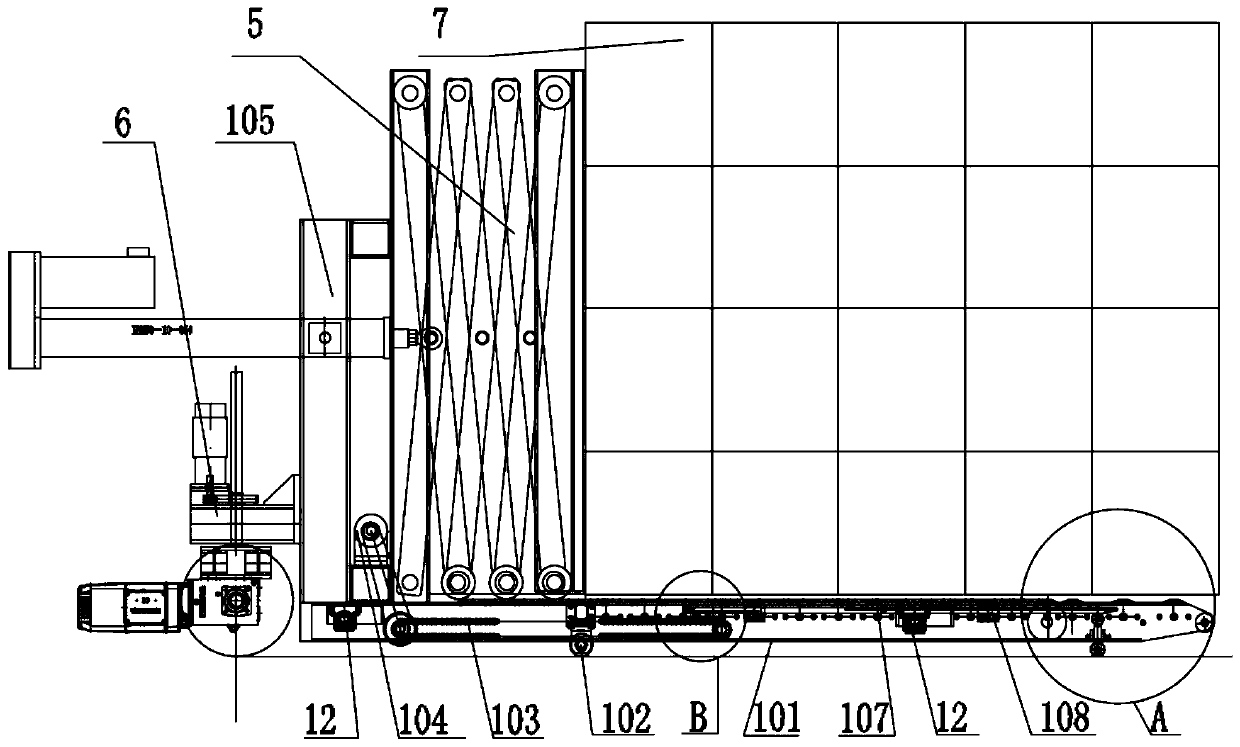

[0044] Such as figure 1 and figure 2 As shown, the pallet-less automatic loading machine for large trucks of the present embodiment includes a rail car 4, which is connected with a mobile floor 3 perpendicular to the direction of motion of the rail car 4 through a drive device 42, and a mobile floor 3 is installed on the mobile floor 3. Flatbed truck 1 walking along it, one side of the flatbed truck 1 is equipped with a push pedal mechanism 5 moving in the horizontal and vertical directions, and the flatbed truck 1 is equipped with an automatic height-adjusting mechanism 6 that integrally lifts it and the push pedal mechanism 5, One side of the push plate mechanism 5 is also docked with a pull-back mechanism 2 installed on the flatbed cart 1 to drive the flatbed cart 1 to move.

[0045] Such as Figure 3-Figure 7 As shown, the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com