90-degree automatic cylinder rotating and material receiving mechanism

A technology of automatic rotation and cylinder block, applied in the field of machinery, can solve the problems affecting the processing cost and quality of the cylinder block, the cylinder block bump, personal injury, etc., to achieve unmanned operation, avoid bump damage, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

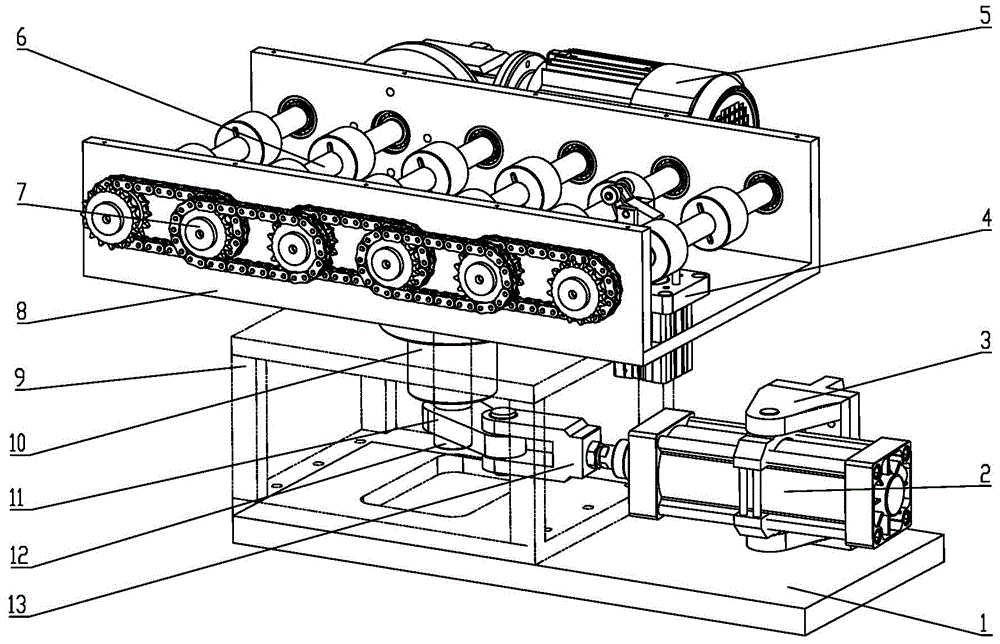

[0012] Such as figure 1 Shown in the figure: cylinder body automatic rotary feeding mechanism, characterized in that it includes a bottom plate 1 on which a bracket 9 and a cylinder seat 3 are arranged;

[0013] The rotary cylinder 2 is arranged on the cylinder seat 3; the piston rod of the rotary cylinder 2 is connected with the cylinder joint 13, the cylinder joint 13 is hinged with the connecting rod 11, and the other end of the connecting rod 11 is fixedly connected with the rotary shaft 12; at the upper end of the rotary shaft 12 Install the revolving base 10, and install the revolving frame 8 on the revolving base 10;

[0014] A plurality of driving shafts 6 are arranged side by side in the revolving frame 8, and one end of the revolving frame 8 is provided with a limit cylinder 4 for blocking the cylinder body to be rotated; the limit cylinder 4 can do lifting motion; One end of one drive shaft in the drive shaft 6 is connected to the drive motor 5; the end of each dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com