Automatic button conveying device with button recognizing and adjusting function

A button and button feeding technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as low efficiency, high labor costs, and long time spent, so as to avoid errors, save device space, and maintain The effect of the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

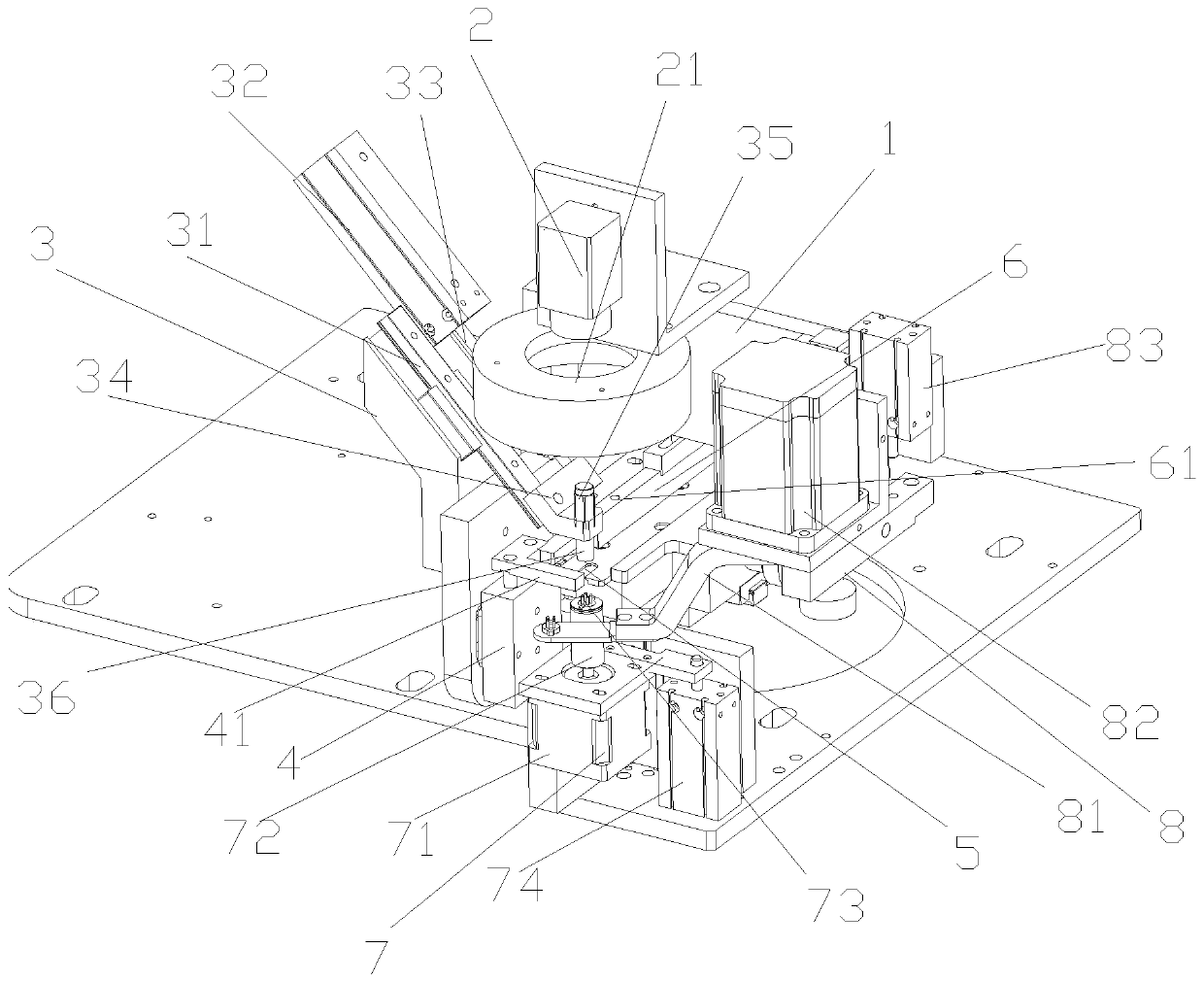

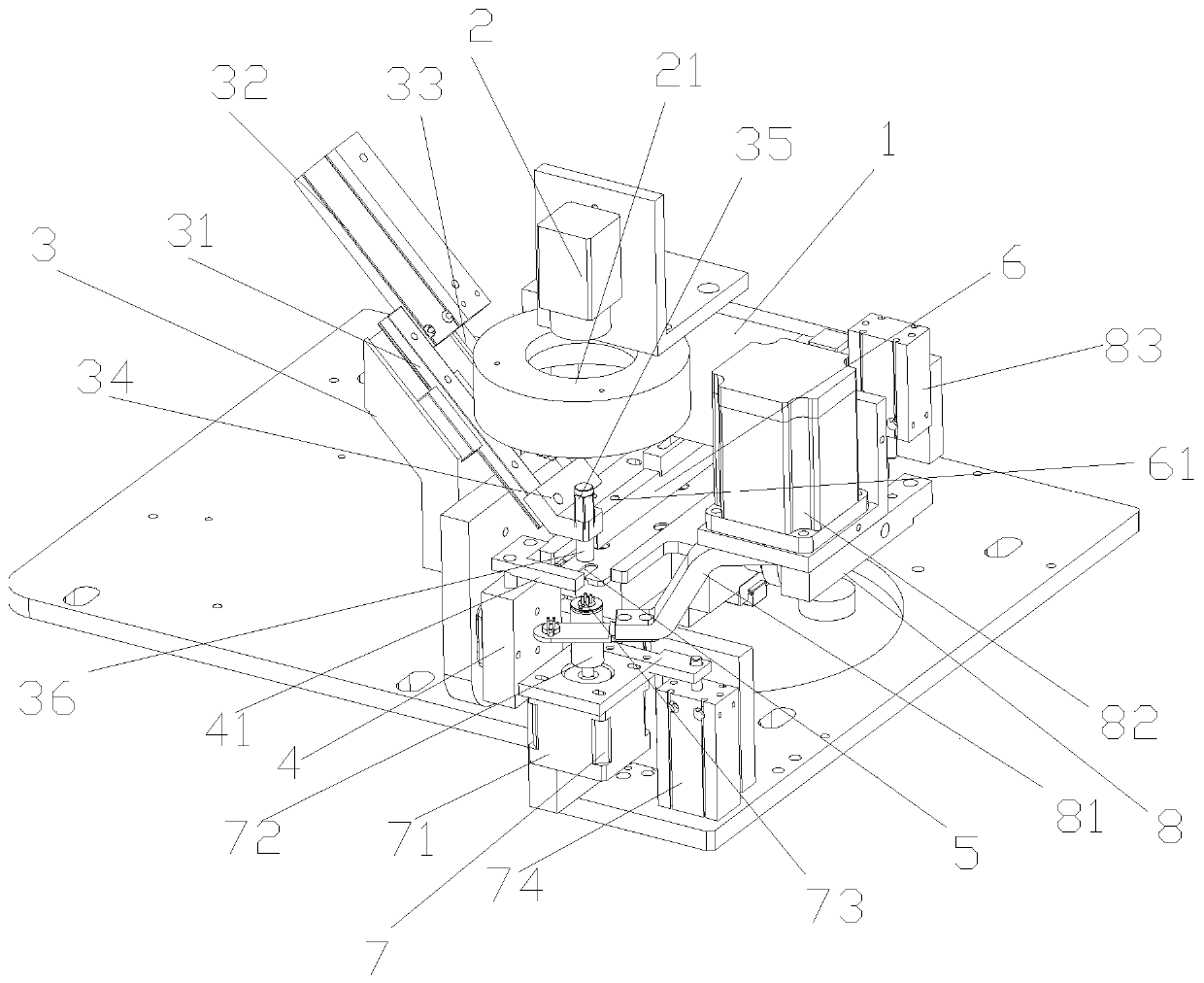

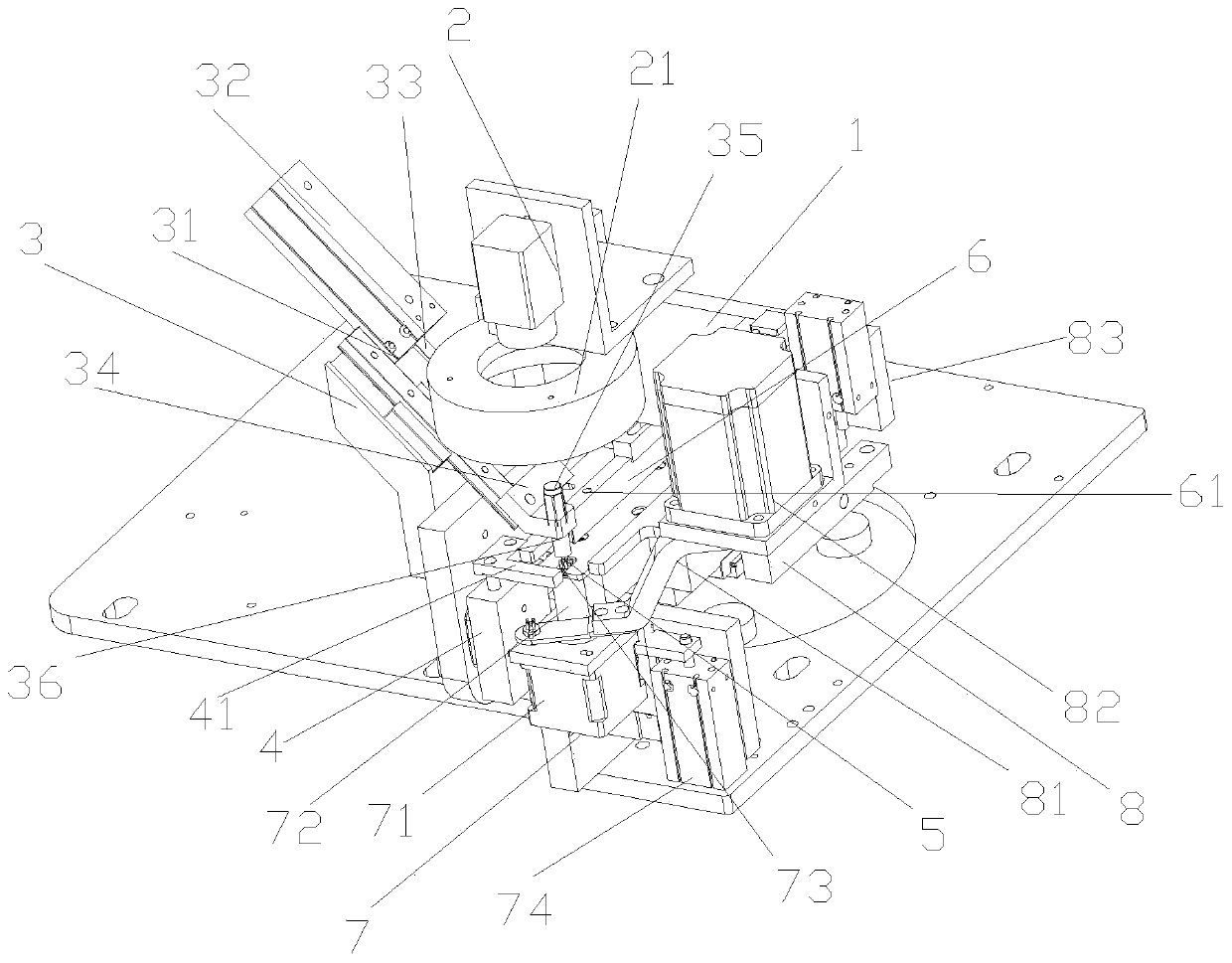

[0025] Embodiment 1, an automatic button feeding device with button recognition and adjustment function of the present invention, comprising an automatic button feeding device 1, an image acquisition device 2, a button adjusting device 7 and a button pressing device 3, the automatic button feeding device 1 is An image acquisition device 2 for collecting the surface pattern of the button at the button outlet is provided, and a button pressing device 3 that moves on an inclined slide rail 31 is provided above the button outlet 5 of the automatic button feeding device. Button adjustment device 7 in the button direction at the 5 button outlets, the 5 button outlets of the automatic button feeding device 1 are through holes with openings on the side, and the image acquisition device 2 transmits the collected button surface image information to the automatic button feeding device control system; the control system has a button direction recognition function, and judges the actual dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com