Modularly-designed pull rod type traction device

A modular design and traction device technology, which is applied in the field of rail transit, can solve problems such as unfavorable vehicle performance and small stiffness, achieve good performance and simplify the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in detail.

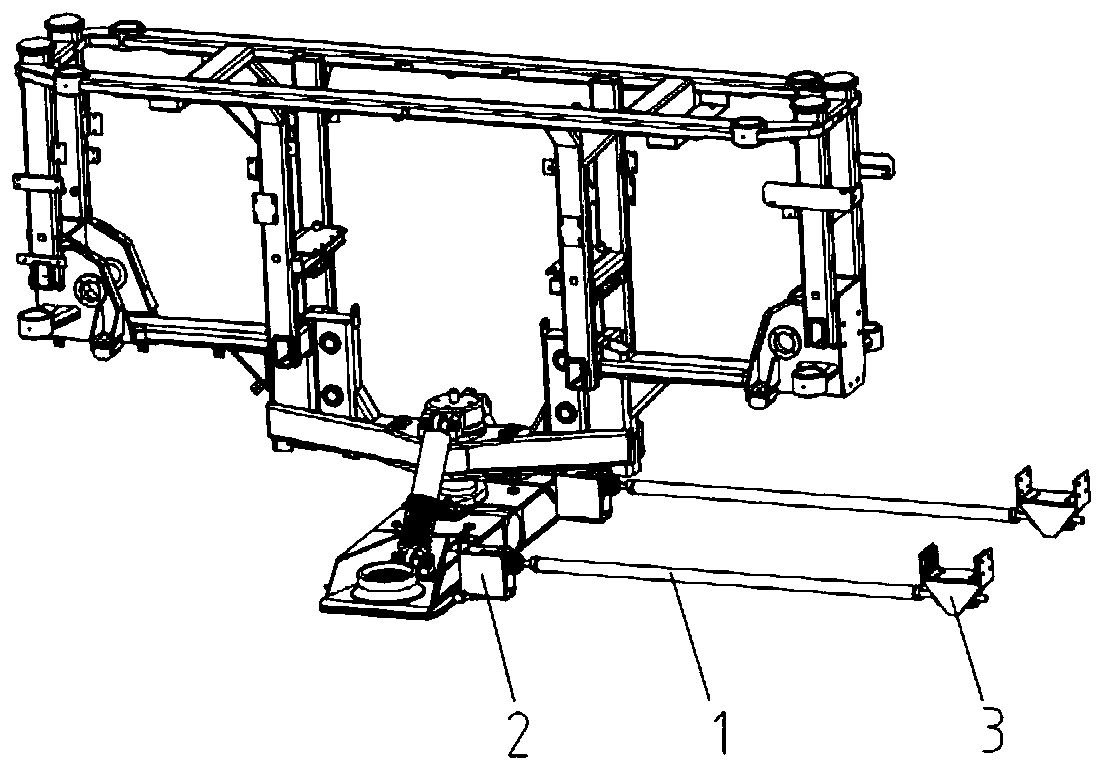

[0022] see figure 1 , the modular design pull-rod traction device 1 of the present invention is installed in pairs on the two mounting seats-2 of the bolster of the suspended monorail bogie, arranged symmetrically to the longitudinal plane, the other end of the modular design rod-type traction device 1 Installed on the two mounts 23 of the car body, it is used to transmit the longitudinal force of the vehicle during traction braking.

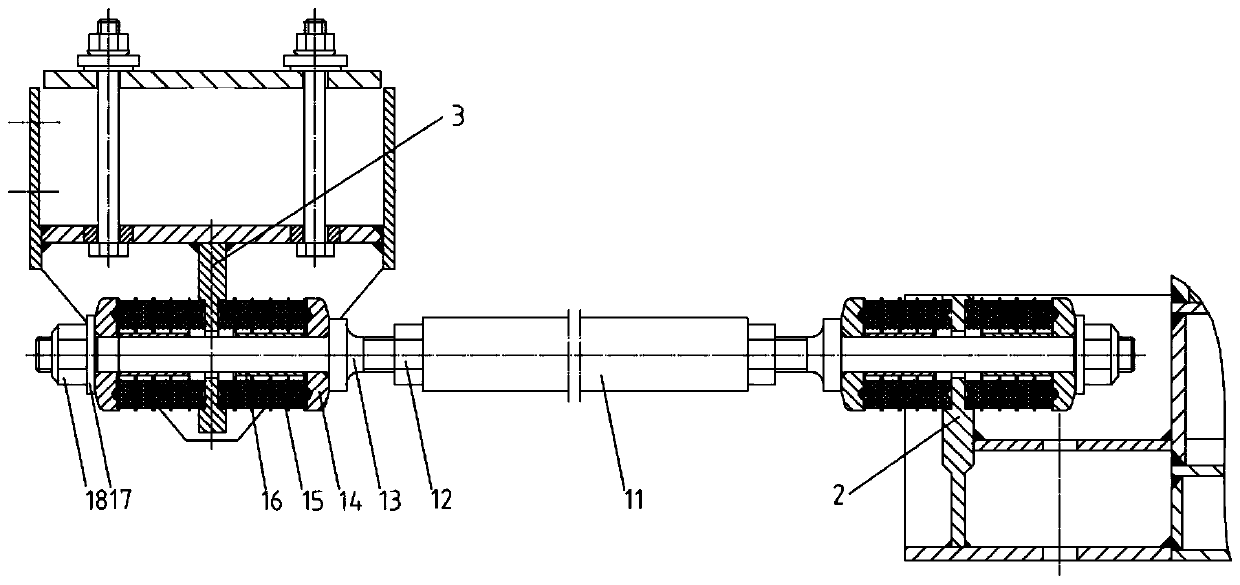

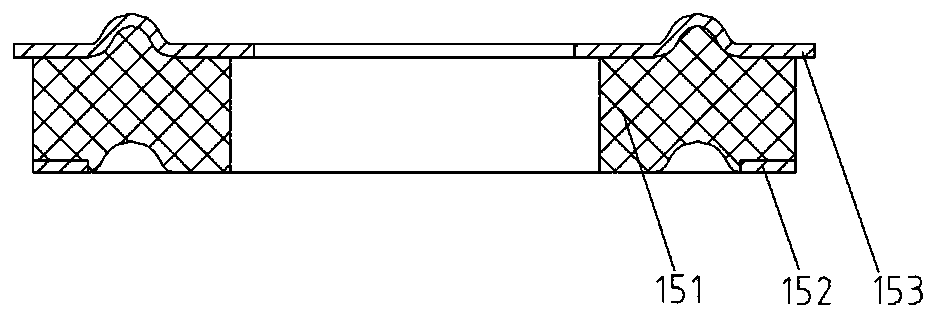

[0023] Such as figure 2 Shown, a kind of modular design pull rod type traction device, comprises pull rod 11, also comprises two end threaded rods 13 and several rubber springs 15, and the two ends of pull rod 11 are threadedly connected and locked with the connecting ends of end threaded rods 13 respectively. Tight, the rubber spring 15 is sequentially strung in from the free end of the end threaded rod 13 to the direction of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com