A kind of bag film in PE box and preparation method thereof

A bag-in-box and film cooling technology, which is applied in the field of flexible packaging, can solve problems such as food safety hazards, achieve good light protection and oxygen barrier performance, improve storage and transportation efficiency, and improve the effect of oxygen barrier capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation of bag-in-PE film includes the following steps:

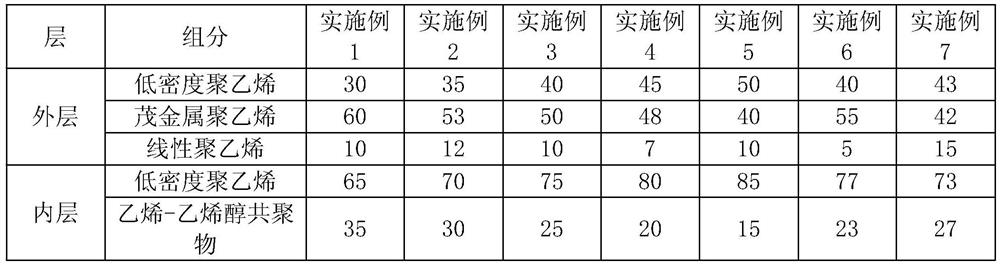

[0025] Step 1: Weigh each raw material according to Table 1, mix each raw material according to the respective formulas of the outer layer and the inner layer, and obtain the outer layer mixture and the inner layer mixture respectively;

[0026] Step 2: Put the outer layer compound and the inner layer compound into the hopper of the extruder respectively. The temperature of the extruder is 160°C, and perform double-layer co-extrusion blown film processing to obtain a film, in which the thickness of the inner layer is 0.002mm , the thickness of the outer layer is 0.01mm;

[0027] Step 3: cooling and winding the film to obtain the PE bag-in-box film.

[0028] The tensile strength of the bag film in the prepared PE box is 46N / mm, the elongation at break is 282%, and the oxygen transmission rate (23°C, 50%RH) is 3.62cm 3 / m 2 ·24h·0.1Mpa, with good strength and sealing oxygen barrier effect.

[0029] Tabl...

Embodiment 2

[0032] To prepare the bag-in-PE film, see Table 1 for the amount of each raw material, and the method is the same as in Example 1, except that the temperature of the extruder in step 2 is 150°C, the thickness of the inner layer of the film is 0.002mm, and the thickness of the outer layer is 0.012mm.

[0033] The tensile strength of the bag film in the prepared PE box is 48N / mm, the elongation at break is 274%, and the oxygen transmission rate (23°C, 50%RH) is 3.75cm 3 / m 2 ·24h·0.1Mpa, with good strength and sealing oxygen barrier effect.

Embodiment 3

[0035] To prepare the bag-in-PE box film, see Table 1 for the amount of each raw material, and the method is the same as in Example 1, except that the temperature of the extruder in step 2 is 165°C.

[0036] The tensile strength of the bag film in the prepared PE box is 53N / mm, the elongation at break is 272%, and the oxygen transmission rate (23°C, 50%RH) is 3.70cm 3 / m 2 ·24h·0.1Mpa, with good strength and sealing oxygen barrier effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com