Distributing system of green full-body brick

A technology of distributing system and full-body brick, applied in auxiliary molding equipment, supply device, ceramic molding machine, etc., can solve the problems of slow cutting speed and high cost of changing production, and achieve the effect of strong applicability, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

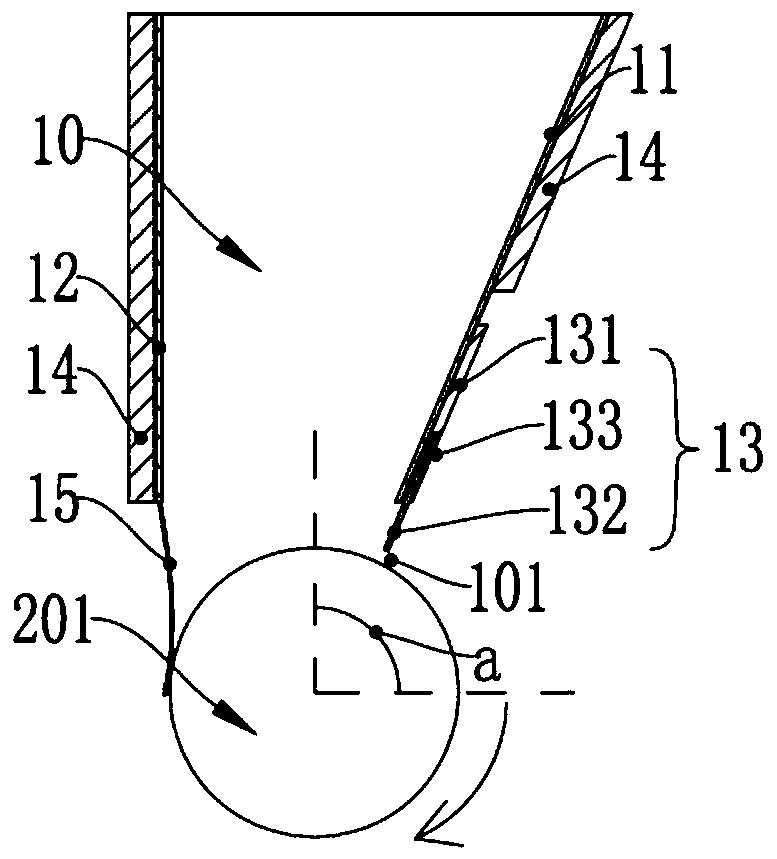

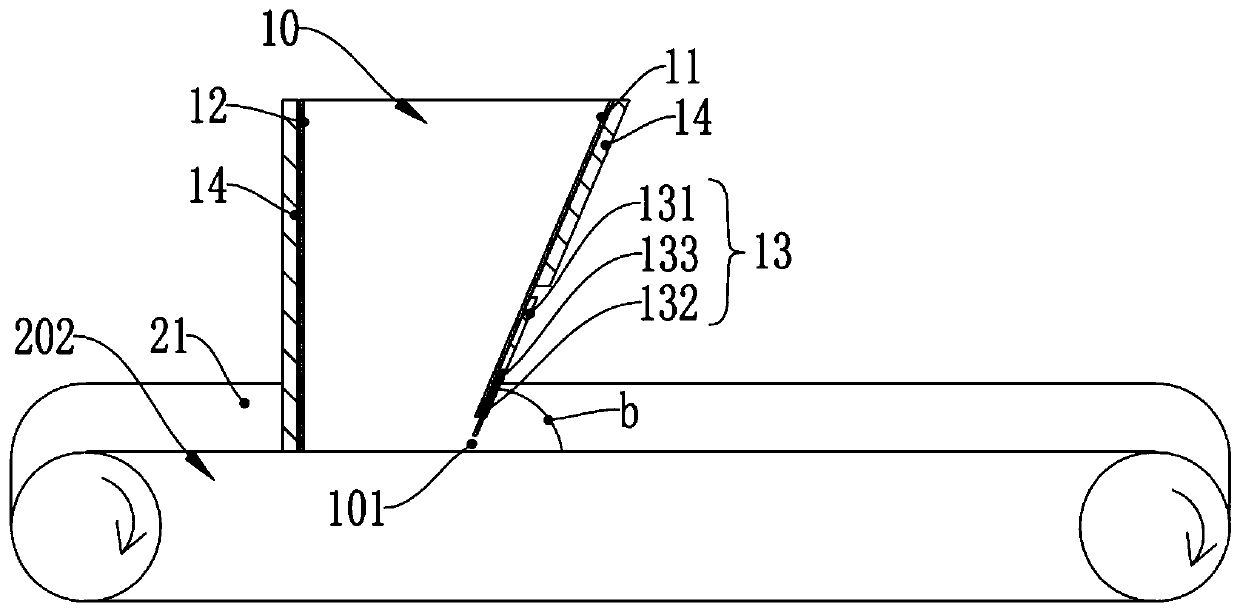

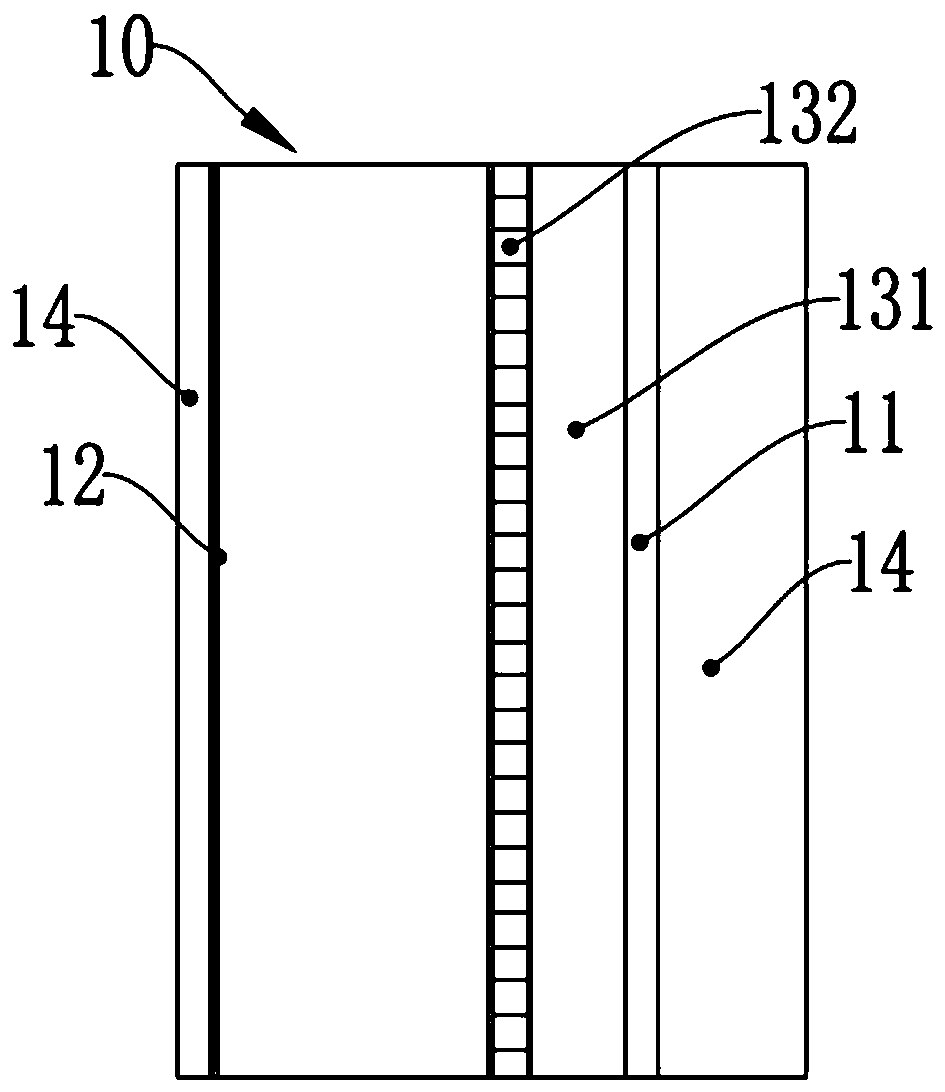

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] A system for distributing whole body adobes, comprising a distributing device and a main belt 3, the distributing device comprising a powder distributing structure 1, a blanking control device and a secondary belt 2;

[0034] The powder material distribution structure 1, the secondary belt 2 and the main belt 3 are arranged step by step from top to bottom, and the powder material distribution structure 1 is arranged with several feeding holes 101, each of the feeding The openings of the holes 101 are respectively controlled by the feeding control device, and the feeding control device makes the powder be fed through different feeding holes 101 by controlling the openings of each of the feeding holes 101, and the powder is fed on the auxiliary belt. 2. Form a texture or pattern with controllab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com