Preparation device and shaping method of ultrafine grain and nanograin blanks

A technology for preparing devices and nanocrystals, which is applied to manufacturing tools, metal processing equipment, containers for metal to be extruded, etc., can solve problems such as poor performance, increase production costs, and single production, so as to reduce production costs and improve production efficiency. , the effect of excellent organizational performance

Inactive Publication Date: 2019-08-23

NORTHWESTERN POLYTECHNICAL UNIV

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing equipment for producing tubes, rods, wires, and profiles has the advantages of energy saving, high yield, and short process, but the products produced have coarse grains, poor performance, and single production, and cannot simultaneously produce tubes, rods, Various products such as wires and profiles cannot be used in the production of liquid, semi-solid, solid, powder and other materials with a certain solid phase ratio at the same time, which severely limits the diversification of production products and increases production costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0039] The device of the present invention is used to prepare high-plasticity Al-5.1Mg-0.3Sn (wt.%) alloy rods. The extrusion die adopts a solid rod extrusion die that can simultaneously extrude 4 rods. The rod product has a diameter of 10mm. At the front end of the device of the present invention, online quenching is used, and the online quenching temperature is 300°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

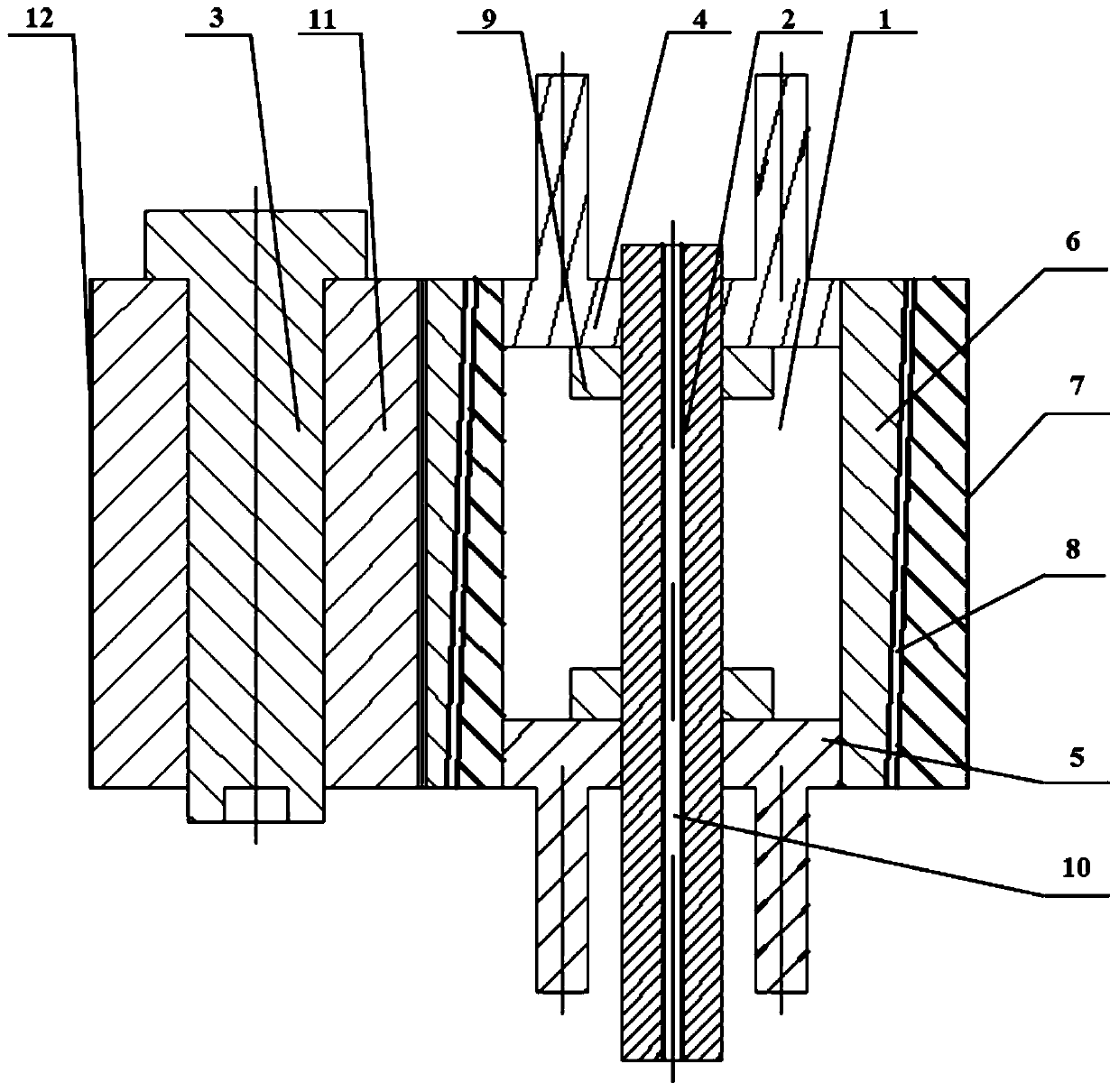

The invention discloses a preparation device and a shaping method of ultrafine grain and nanograin blanks. The preparation device comprises a rotary extrusion sleeve, a main shaft and an auxiliary shaft, wherein the rotary extrusion sleeve is installed on the main shaft, and equipped with a front sealed cap loading and unloading hydraulic device and a rear sealed cap loading and unloading hydraulic device, the rotary extrusion sleeve comprises a main shaft sleeve wheel, a main shaft sleeve wheel external gear and a main shaft sleeve wheel cooling system, extrusion dies are installed on the front sealed cap loading and unloading hydraulic device and the rear sealed cap loading and unloading hydraulic device, the main shaft is equipped with a main shaft cooling system, and rotated through amotor, the auxiliary shaft is driven by the motor, equipped with a key groove, and connected with an auxiliary shaft sleeve wheel through a flat key, and the auxiliary shaft sleeve wheel is equipped with an auxiliary shaft sleeve wheel external gear. The preparation device of the ultrafine grain and nanograin blanks can simultaneously produce the ultrafine grain and nanograin blanks, and bars, pipes, wires, filaments, profiled bars and the like of the ultrafine grain and nanograin blanks, is low in energy consumption, reduces production cost, and can be used in efficient production of materials of liquid, and semisolid, solid, powder and the like which have a certain solid fraction.

Description

Technical field [0001] The invention relates to the technical field of short-flow processing of metal materials, and more specifically to a preparation device and a forming method of ultrafine crystal and nanocrystal blanks. Background technique [0002] Existing equipment for the production of tubes, rods, wires, and profiles has the advantages of energy saving, high yield, short process, etc., but the produced products have coarser grains, poor performance, and single production. Tubes, rods, and rods cannot be produced at the same time. A variety of products such as threads and profiles cannot be used in the production of liquid, semi-solid, solid, powder and other materials with a certain solid phase rate at the same time, which severely limits the diversification of production products and increases production costs. Summary of the invention [0003] The embodiment of the present invention provides a preparation device and a forming method of ultra-fine crystal and nanocrysta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C23/21B21C25/02B21C27/00B21C29/00

CPCB21C23/211B21C25/02B21C27/00B21C29/00

Inventor 管仁国白景元张晋陈小林杨博威王玉刘振杰

Owner NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com