A high-hardness raw ore stripping type automatic crushing device and its application method

A crushing device and stripping technology, applied in grain processing and other directions, can solve the problems of low crushing efficiency, easy to cause chipping, easy to wear and consume large amount, and achieve the effects of simple structure, improved efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

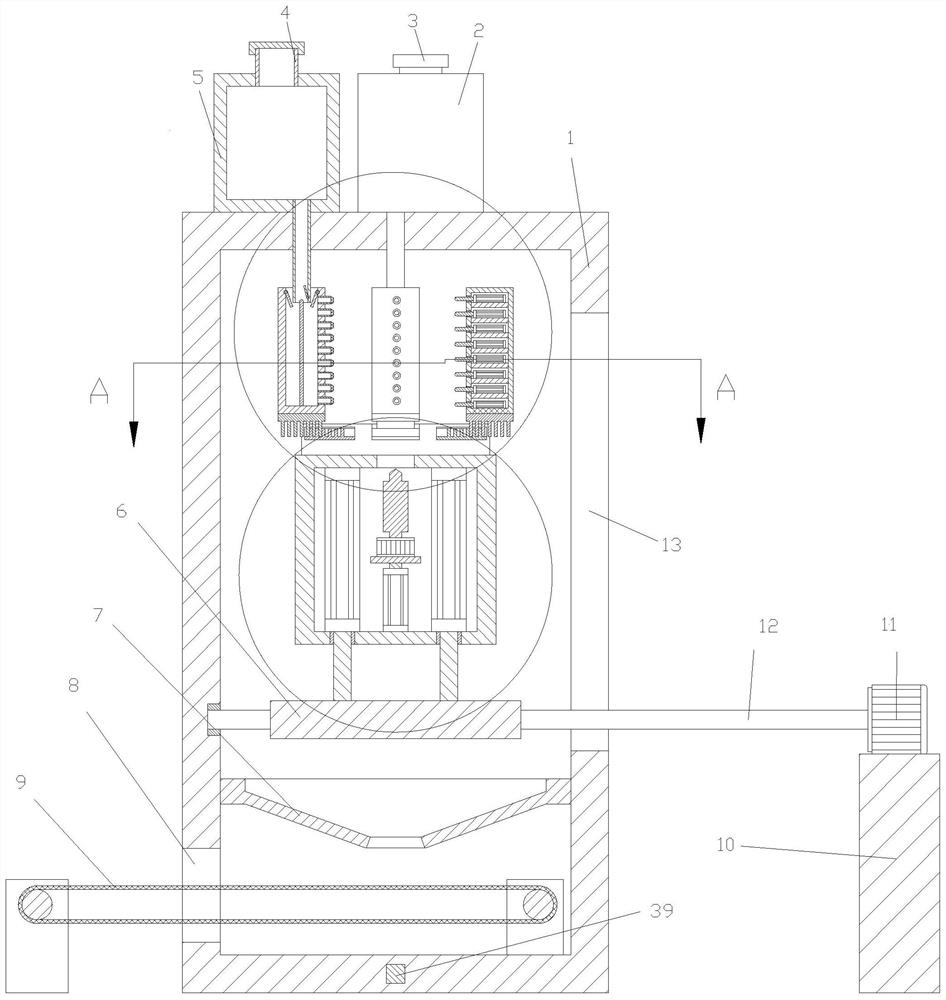

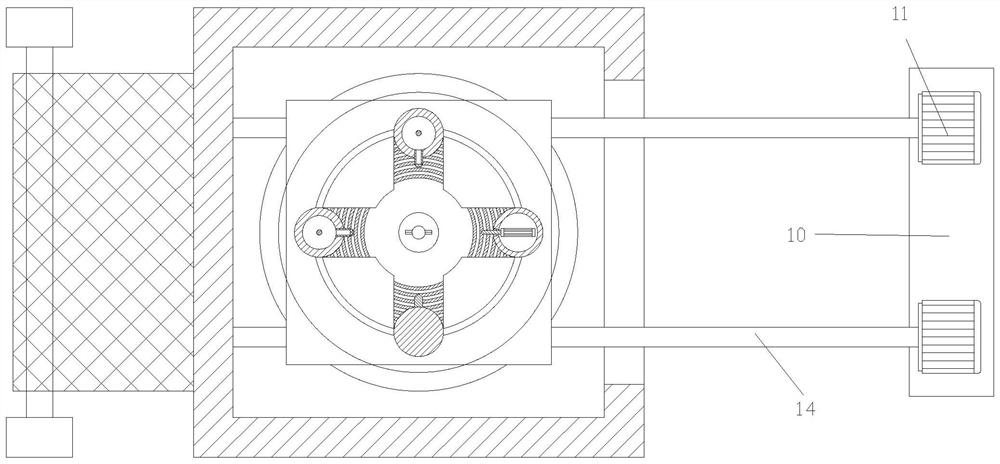

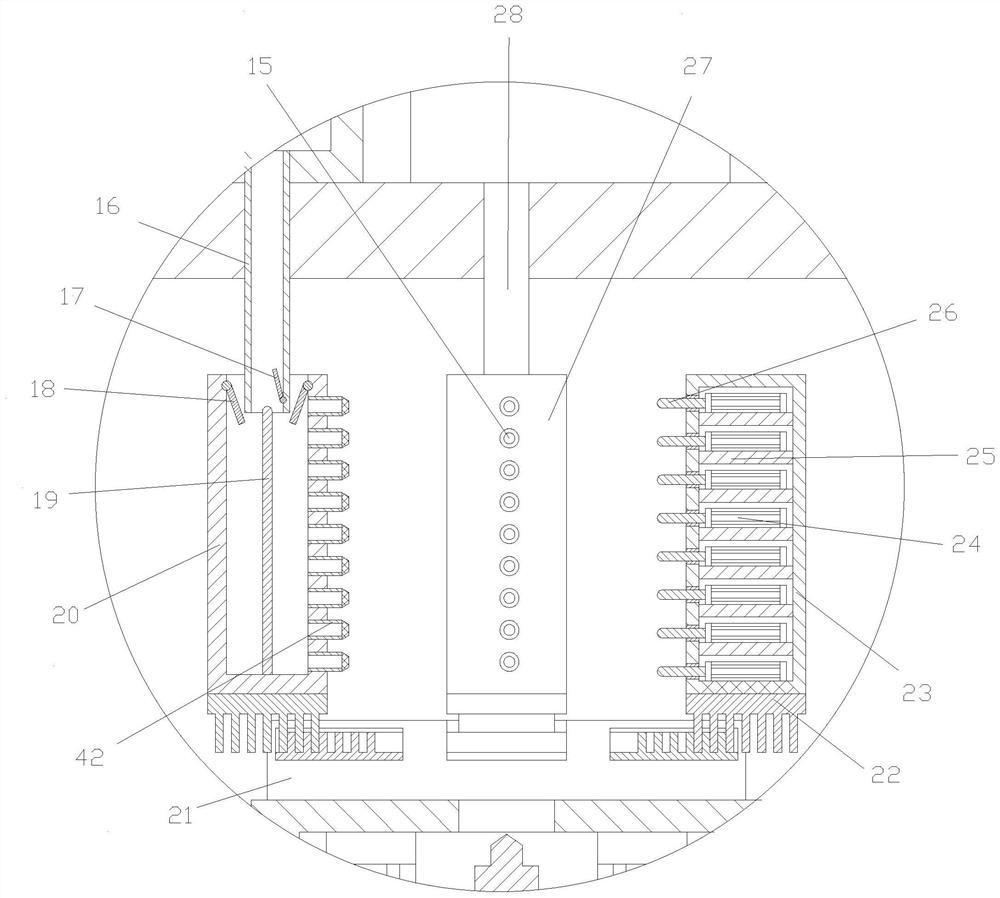

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Refer to attached figure 1 , 2, 3, 4, 5: This high-hardness raw ore stripping type automatic crushing device in the present embodiment includes a box body-1, a four-jaw chuck 21, and a chuck slider 22, and the top of the box body-1 is fixedly installed with Fuel tank 5, the right side of the fuel tank 5 is provided with a water tank 2 fixedly installed on the top of the casing one 1, the water tank 2 and the top of the fuel tank 5 are respectively provided with a water inlet 3 and a feeding port 4, the water tank 2 and Conduit one 16 and conduit two 28 are installed respectively at the bottom of fuel tank 5, and the bottom of described conduit one 1 passes through fuel tank 5 inwall bottom and casing one 1 inwall top and then reaches casing one 1 inside, and described conduit two 28 bottoms After passing through the bottom of the inner wall of the water tank 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com