Polypeptide repairing emulsion and preparing method thereof

A technology of emulsion and polypeptide, which is applied in the field of polypeptide repair emulsion and its preparation, can solve the problems of insufficient stability of active ingredients and affect the physiological function of the product, and achieve the effects of promoting skin injury healing, strengthening nutrition and repairing effects, and enhancing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

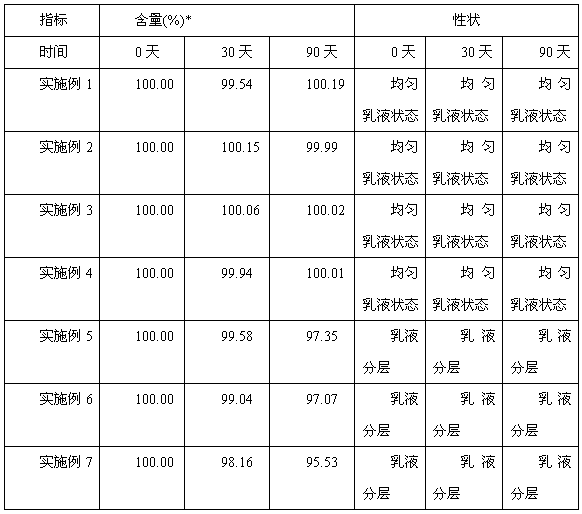

Examples

Embodiment 1

[0033] The raw material composition is shown in Table 1.

[0034] Table 1

[0035] raw material Formula quantity (g) Propylene Glycol 4 xanthan gum 0.4 Allantoin 0.15 Polyacrylic acid 0.15 Sodium hyaluronate 0.15 Acetyl Hexapeptide-8 2 palmitoyl tripeptide 2 Inositol 2 Tripeptide-1 2 copper peptide 2 Acetyl Tetrapeptide-5 1 Creatine 2 palmitoyl tetrapeptide-7 2 Carnosine 2 Methylparaben 0.2 Polysorbate-20 2 panthenol 0.65 Disodium EDTA 0.075 Phenoxyethanol 0.5 Bis(hydroxymethyl) imidazolidinyl urea 0.2 Iodopropynyl butylcarbamate 0.2 Deionized water Make up to 100g

[0036] Made in the following way:

[0037] 1) Mix xanthan gum and 10% deionized water at 85°C and stir evenly, then the mixture is dispersed by ultrasonic, the power of ultrasonic dispersion is 75W, the frequency of ultrasonic dispersion is 50KHz, and the ultrasonic tr...

Embodiment 2

[0043] The raw material composition is shown in Table 2.

[0044] Table 2

[0045] raw material Formula quantity (g) Propylene Glycol 3.5 xanthan gum 0.35 Allantoin 0.125 Polyacrylic acid 0.125 Sodium hyaluronate 0.125 Acetyl Hexapeptide-8 1.75 palmitoyl tripeptide 1.75 Inositol 1.9 Tripeptide-1 1.9 copper peptide 1.9 Acetyl Tetrapeptide-5 1.9 Creatine 1.75 palmitoyl tetrapeptide-7 1.75 Carnosine 1.9 Methylparaben 0.175 Polysorbate-20 1.75 panthenol 0.6 Disodium EDTA 0.065 Phenoxyethanol 0.45 Bis(hydroxymethyl) imidazolidinyl urea 0.175 Iodopropynyl butylcarbamate 0.175 Deionized water Make up to 100g

[0046] Made in the following way:

[0047]1) Mix xanthan gum and 10% deionized water at 85°C and stir evenly, then the mixture is ultrasonically dispersed, the power of ultrasonic dispersion is 75W, the frequency of ultrasonic dispe...

Embodiment 3

[0053] The raw material composition is shown in Table 3.

[0054] table 3

[0055] raw material Formula quantity (g) Propylene Glycol 3 xanthan gum 0.3 Allantoin 0.2 Polyacrylic acid 0.2 Sodium hyaluronate 0.1 Acetyl Hexapeptide-8 1 palmitoyl tripeptide 3 Inositol 1 Tripeptide-1 3 copper peptide 1 Acetyl Tetrapeptide-5 1 Creatine 3 palmitoyl tetrapeptide-7 3 Carnosine 1 Methylparaben 0.1 Polysorbate-20 3 panthenol 0.8 Disodium EDTA 0.05 Phenoxyethanol 0.2 Bis(hydroxymethyl) imidazolidinyl urea 0.3 Iodopropynyl butylcarbamate 0.3 Deionized water Make up to 100g

[0056] Made in the following way:

[0057] 1) Mix xanthan gum and 10% deionized water at 80°C and stir evenly, then the mixture is ultrasonically dispersed, the power of ultrasonic dispersion is 80W, the frequency of ultrasonic dispersion is 40KHz, and the ultrasonic treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com