Rice Transplant Synchronous Fertilizer

A technology of fertilizer applicator and rice, which is applied to fertilizer applicator, transplanting machine, fertilizer distributor, etc., can solve the problems of poor fertilizer effect, poor soil fluidity, easy damage, etc., and achieves the effect of simple structure, smooth conveying, and improved time duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

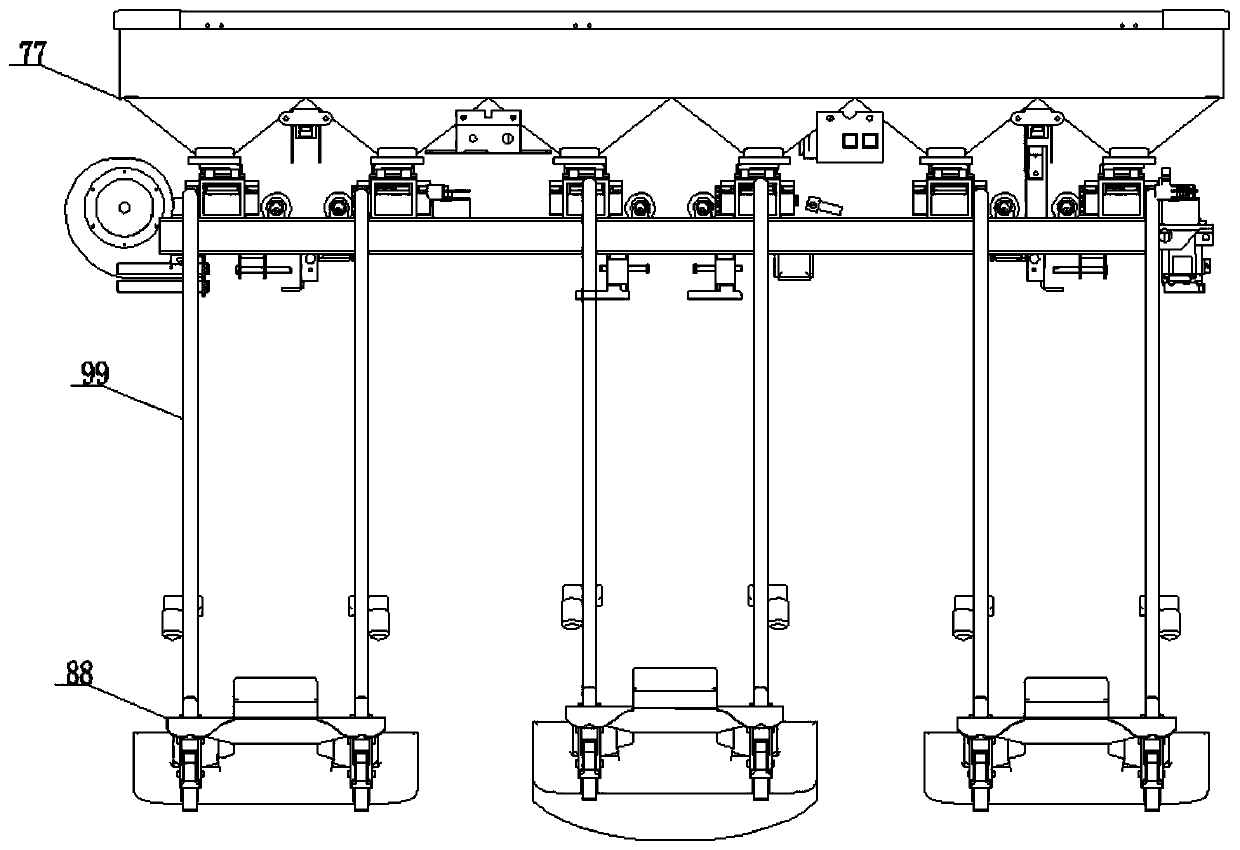

[0046] Such as Figure 1-4 As shown, the synchronous fertilization machine for rice transplanting described in this specific embodiment includes driving agricultural machinery 55, planting mechanism 66, fertilizer discharge and conveying device 77, ditch fertilization and soil covering device 88, fertilization hose 99; fertilizer discharge and conveying Device 77 and ditch fertilization and soil covering device 88 are connected by fertilizing hose 99 to carry out the transportation of fertilizer; Drive the planting mechanism 66, the fertilizer discharge and conveying device 77 and the ditch fertilization and soil covering device 88 to walk by driving the agricultural machinery 55.

[0047] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com