A Multi-motor Synchronous Control Method Based on Identification Model

A technology of synchronous control and identification model, which is applied in the direction of speed adjustment of multiple motors, manufacturing tools, accessories of shearing machines, etc., to achieve the effect of good synchronization performance and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, work flow, use method, purpose and effect of the present invention easy to understand, the present invention will be further described below in conjunction with specific implementation examples.

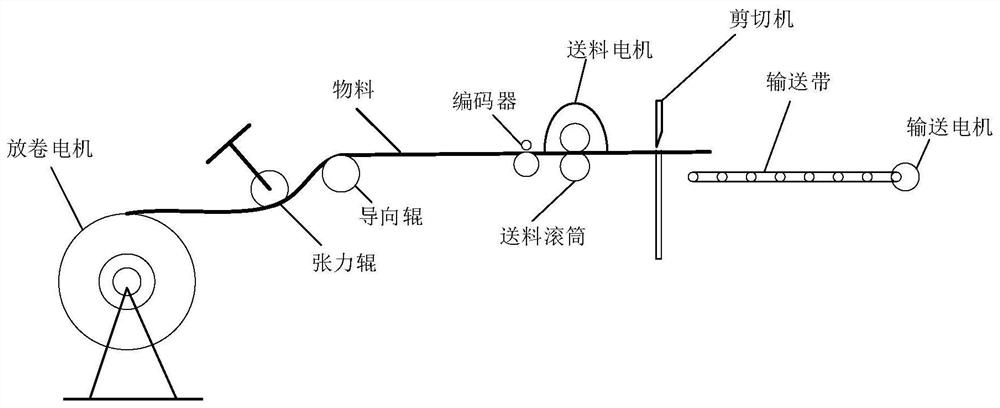

[0042] Build a multi-motor synchronous control scheme for the soft metal strip shearing system, such as figure 1 The composition diagram of the system is shown. The system is mainly composed of three parts: discharging system, shearing system and conveying system. The unwinding system is mainly driven by the unwinding motor to rotate the material disc for automatic unwinding. During the process, the pneumatic tension roller is constantly adjusted to maintain a constant tension; the strip driving and shearing system is the core part of the entire equipment, and the feeding is mainly driven by the feeding motor. Composed of rollers and shearing mechanisms; the conveying system is composed of belts and conveying motors. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com