Bifunctional catalyst for catalyzing ORR and OER and preparation and application of bifunctional catalyst

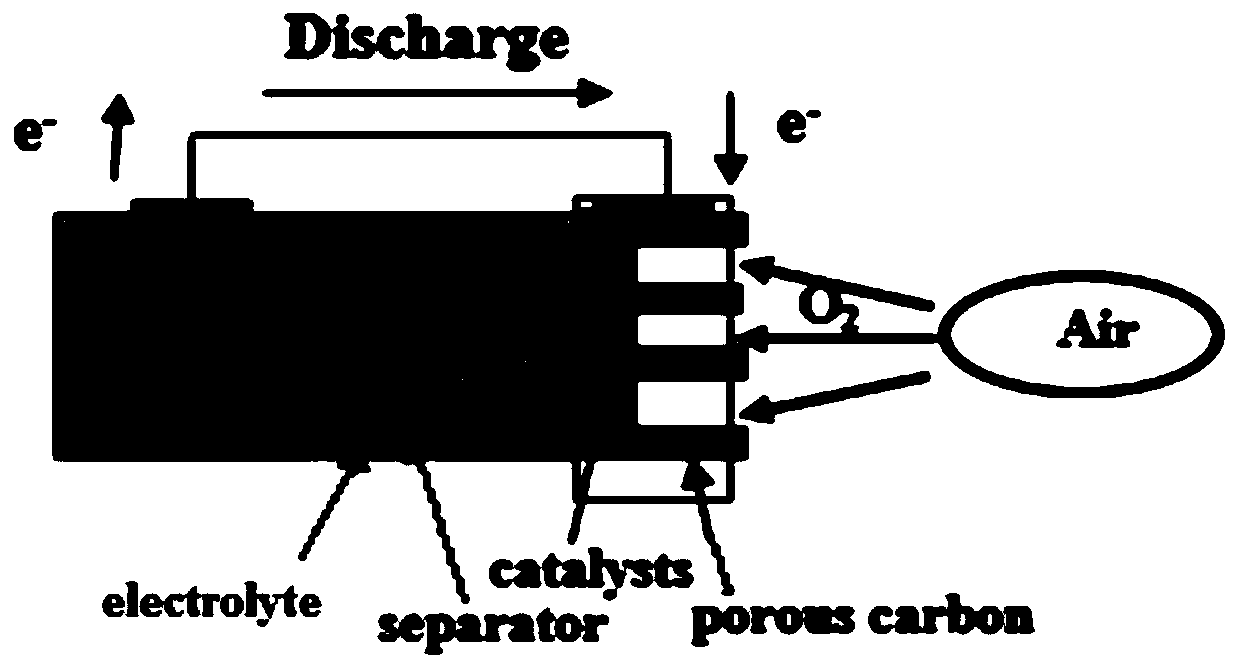

A bifunctional catalyst and catalyst technology, applied in the direction of nanotechnology for materials and surface science, fuel cell half-cells and primary battery half-cells, electrical components, etc., can solve the scarcity of resources and the high cost of noble metal catalysts , cannot be commercialized on a large scale, and achieve the effect of solving high cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

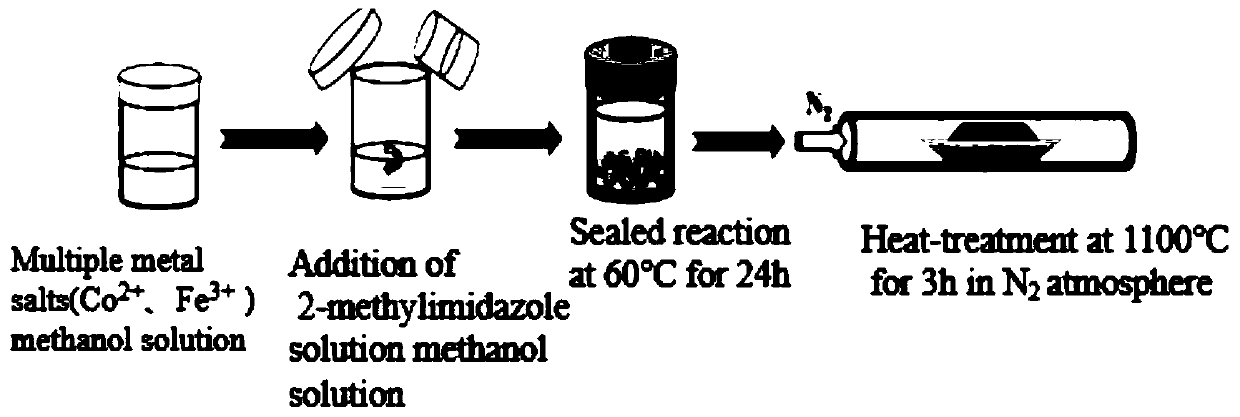

[0043] A method for preparing a nitrogen-doped MOF-based dual-function air catalyst in which binary metals work together in an embodiment of the present invention comprises the following steps:

[0044] Step 1, solvothermal reaction: different amounts of Zn containing metal ions 2+ 、Co 2+ and Fe 3+ The nitrate is dispersed in methanol, and a certain amount of dimethylimidazole is also dispersed in methanol, where Zn 2+ The molar concentration is 0.038mol / L (3.39gZn(NO 3 ) 2 ·6H 2 O dissolved in 300mL methanol), the concentration of dimethylimidazole is an equal volume of Zn 2+ 4 times the molar concentration of Fe 3+ and Co 2+ The molar concentrations are 3% times the Zn 2+ (same as Zn 2+ Disperse in methanol together); mix the uniformly dispersed reactant solutions together, stir for 5 minutes, and stand in a 60° oven for 24 hours, and cool to room temperature naturally after the reaction is complete; centrifugally wash the obtained white precursor solid And drying:...

Embodiment 2

[0047] The preparation method of the embodiment of the present invention, the difference with embodiment 1 only lies in: Fe 3+ The molar concentration is 3% times, Co 2+ The molar concentration is 6% times the Zn 2+ ; Others are identical to Example 1.

Embodiment 3

[0049] The preparation method of the embodiment of the present invention, the difference with embodiment 1 only lies in: Fe 3+ The molar concentration is 3% times, Co 2+ The molar concentration is 9% times the Zn 2+ ; Others are identical to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com