Dividing device

A workpiece and annular frame technology, applied in the field of splitting devices, can solve the problems of incapable chip spacing, uneven heat shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

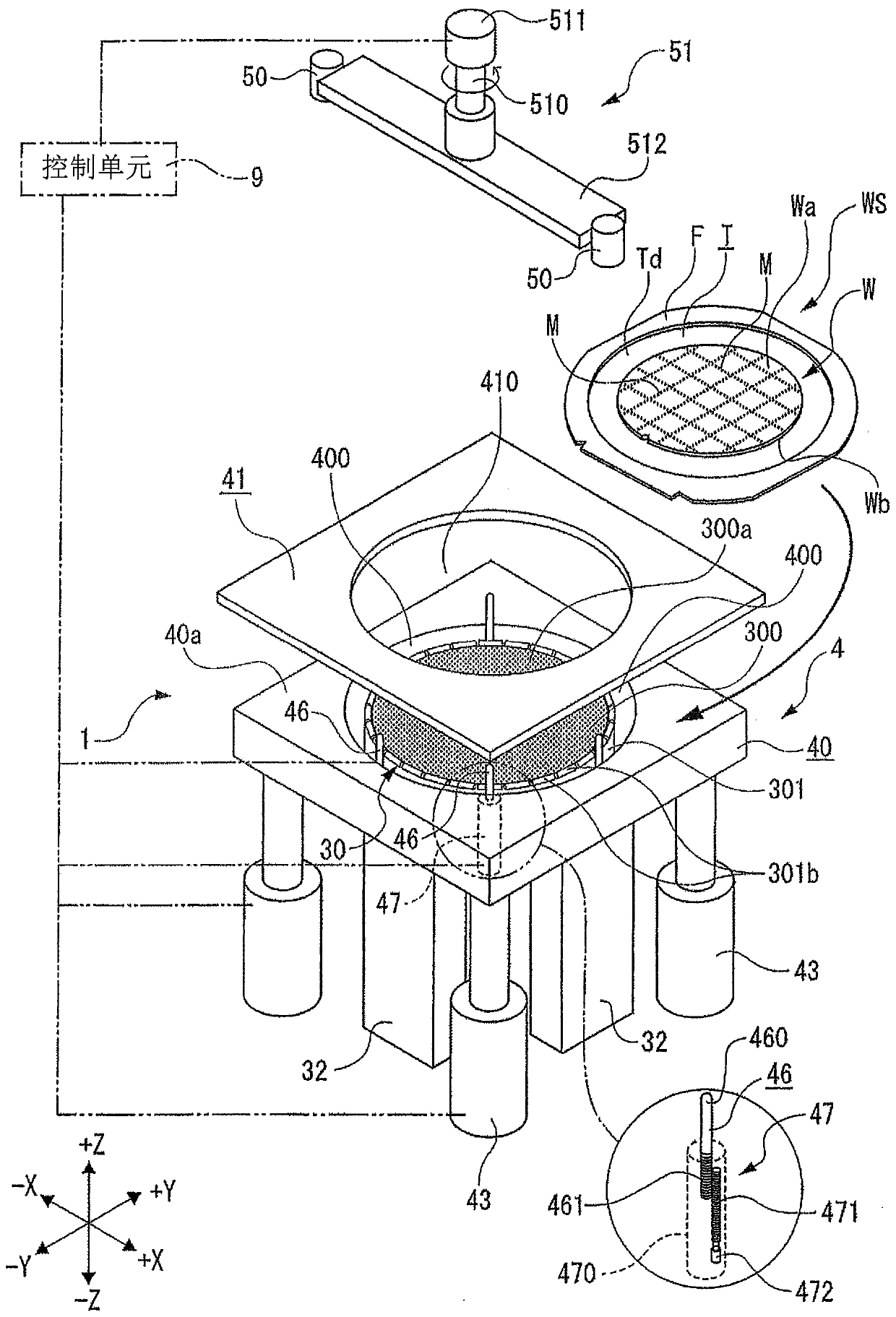

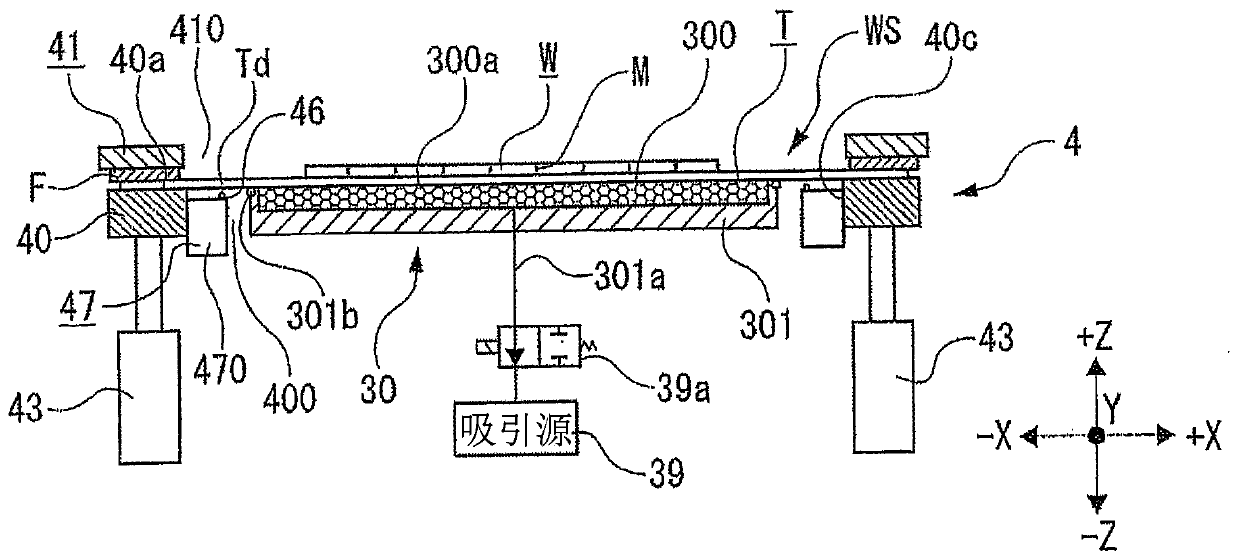

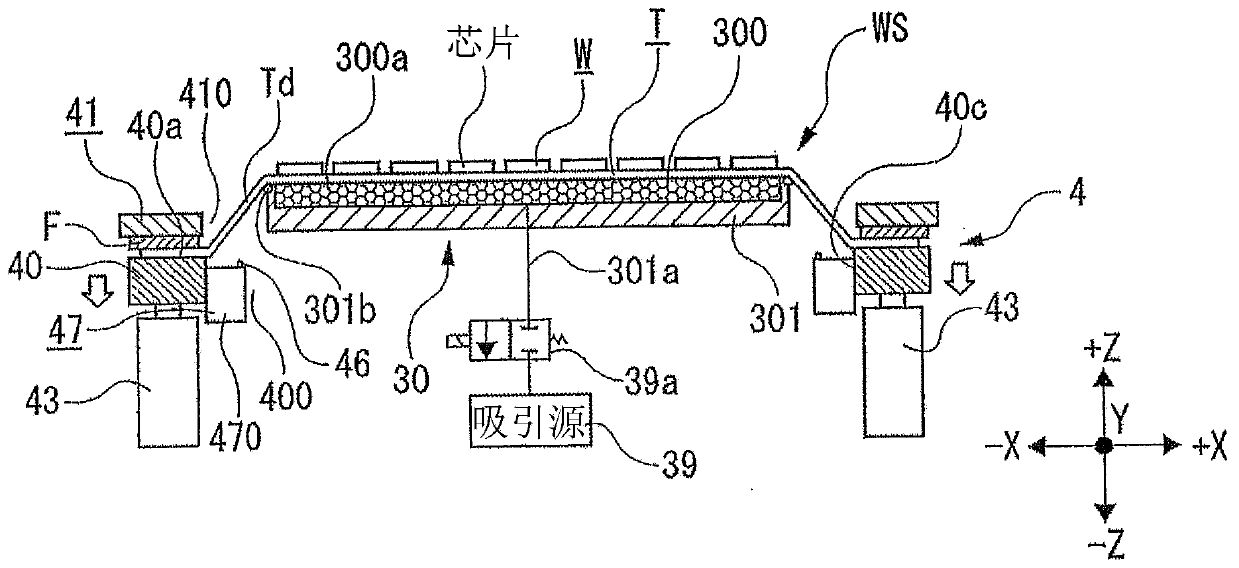

[0032] figure 1 The wafer W shown is, for example, a circular semiconductor wafer made of silicon as a raw material, and a plurality of dividing lines are set vertically on the front surface Wa of the wafer W. Furthermore, devices not shown in the figure are respectively formed in a plurality of grid-like regions partitioned by the planned division lines.

[0033] The wafer W is irradiated with a laser beam of a wavelength transparent to the wafer W along the planned dividing line, and the dividing starting point M (reformed layer M) is continuously formed at a predetermined depth inside the wafer W along the planned dividing line.

[0034] In addition, the division starting point M (modified layer M) is a region where the inside of the wafer W is modified by irradiation of the laser beam so that the intensity is lower than that of the surrounding area. Cracks may extend from the splitting starting point M toward the front Wa or back Wb of the wafer W, respectively. In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com