Multistage heat exchange absorption type refrigeration and heat dissipation system for built-in display cabinet

An absorption refrigeration and heat dissipation system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as poor refrigeration effect of condensing pressure equipment, deterioration of goods in the cabinet, and rise in exhaust temperature of system compressors, etc., to achieve Reduce system failure rate, improve cooling efficiency, and reduce heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As shown in the figure, a multi-stage heat exchange absorption cooling and cooling system for a built-in display cabinet includes a refrigerant circulation device and an absorption refrigeration device 6, wherein:

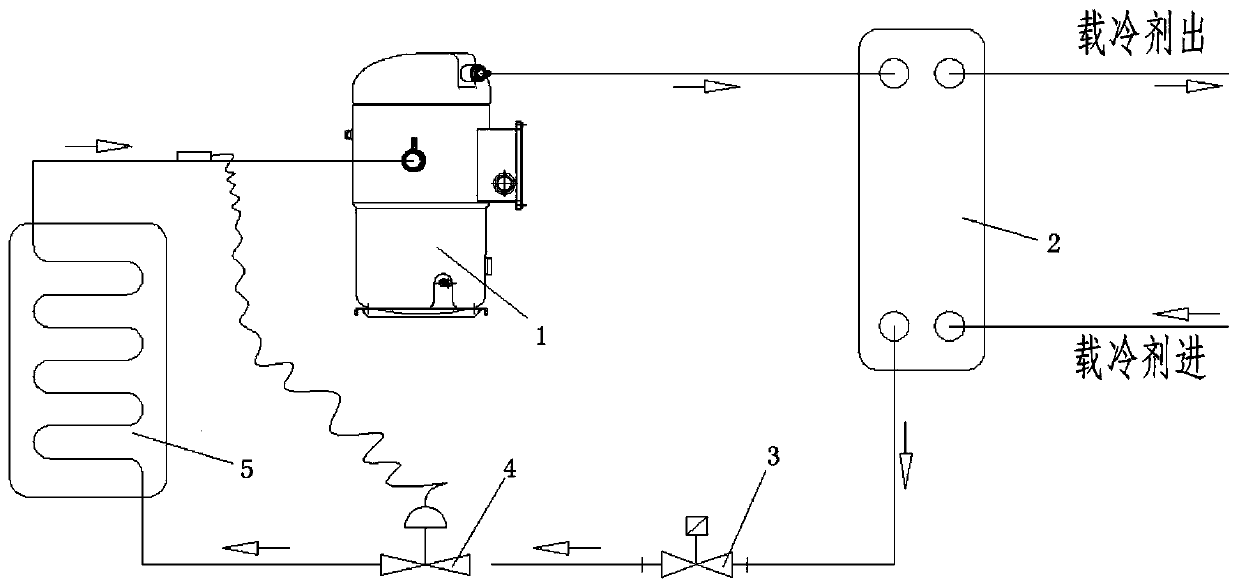

[0041] Refrigerant cycle devices, such as figure 1 As shown, it includes a compressor 1, a plate heat exchanger 2, a solenoid valve 3, a throttling and pressure-reducing component 4, and a first evaporator 5 connected in sequence through pipelines, and the way in which the refrigerant enters the plate heat exchanger 2 is upward. Next, the solenoid valve 3 can control the opening or closing of the refrigerant delivery into the first evaporator 5 and the compressor 1;

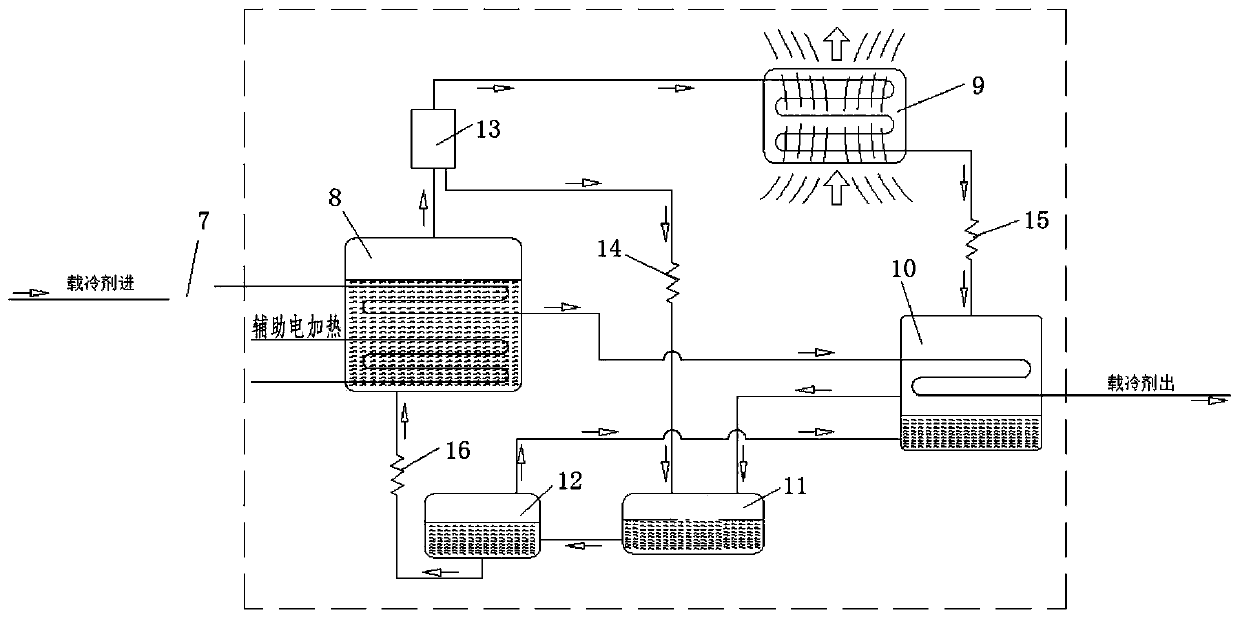

[0042] When ammonia is used as the refrigerant, water is used as the absorbent, and helium is the equilibrium medium, the absorption refrigeration device 6, such as figure 2 As shown, it includes a generator 8, a first condenser 9, a second evaporator 10, a first absorber 11 and a liquid stor...

Embodiment 2

[0057] A multi-stage heat exchange absorption cooling and cooling system for a built-in display cabinet, including a refrigerant circulation device and an absorption refrigeration device 6, wherein:

[0058] The refrigerant cycle device includes a compressor 1, a plate heat exchanger 2, a solenoid valve 3, a throttling and pressure-reducing component 4, and a first evaporator 5, which are sequentially connected through pipelines. The refrigerant enters the plate heat exchanger 2 in a manner In order to go in and out, the solenoid valve 3 can control the opening or closing of the refrigerant delivery into the first evaporator 5 and the compressor 1;

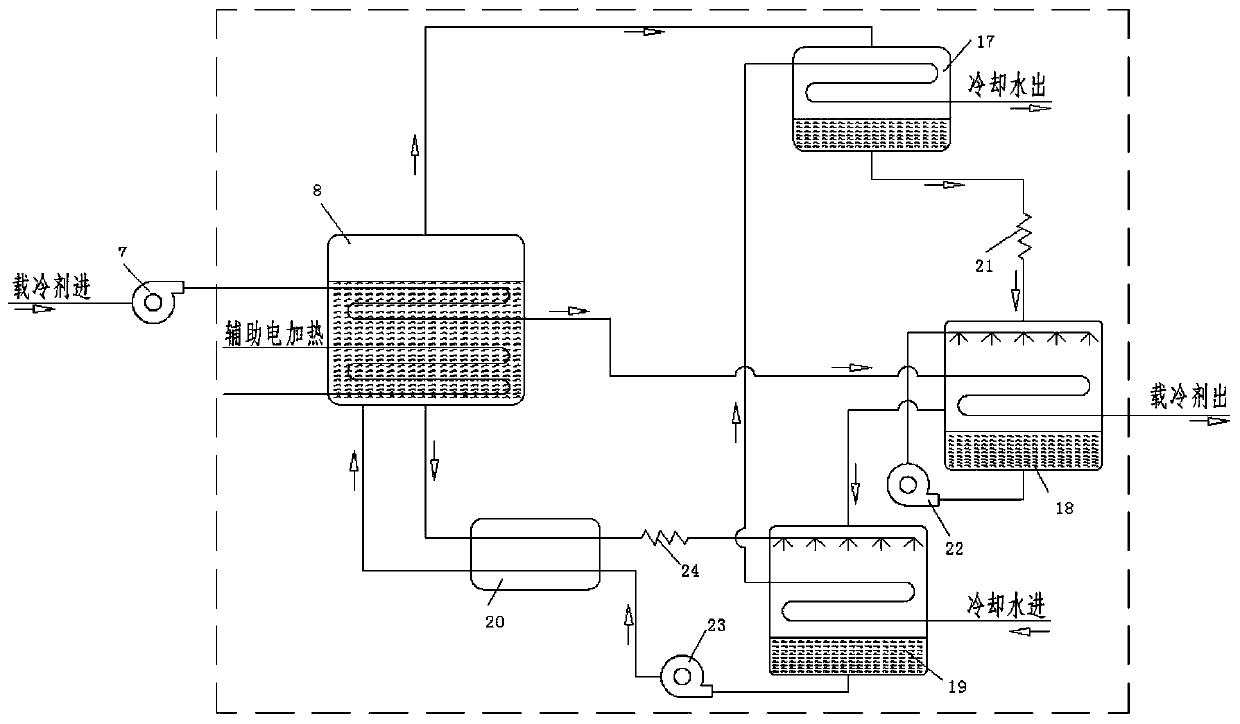

[0059] When water is used as the refrigerant and lithium bromide solution is used as the absorbent, the absorption refrigeration device 6 includes a generator 8, a second condenser 17, a third evaporator 18, a second absorber 19 and a heat exchanger 20, and the generator 8 It is connected with the third evaporator 18, the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com