Hydraulic oil cylinder piston rod adjusting device

A technology for adjusting devices and hydraulic cylinders, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of unilateral wear of seals and guide elements, oil leakage of hydraulic cylinders, etc., and achieve the effect of avoiding unilateral wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

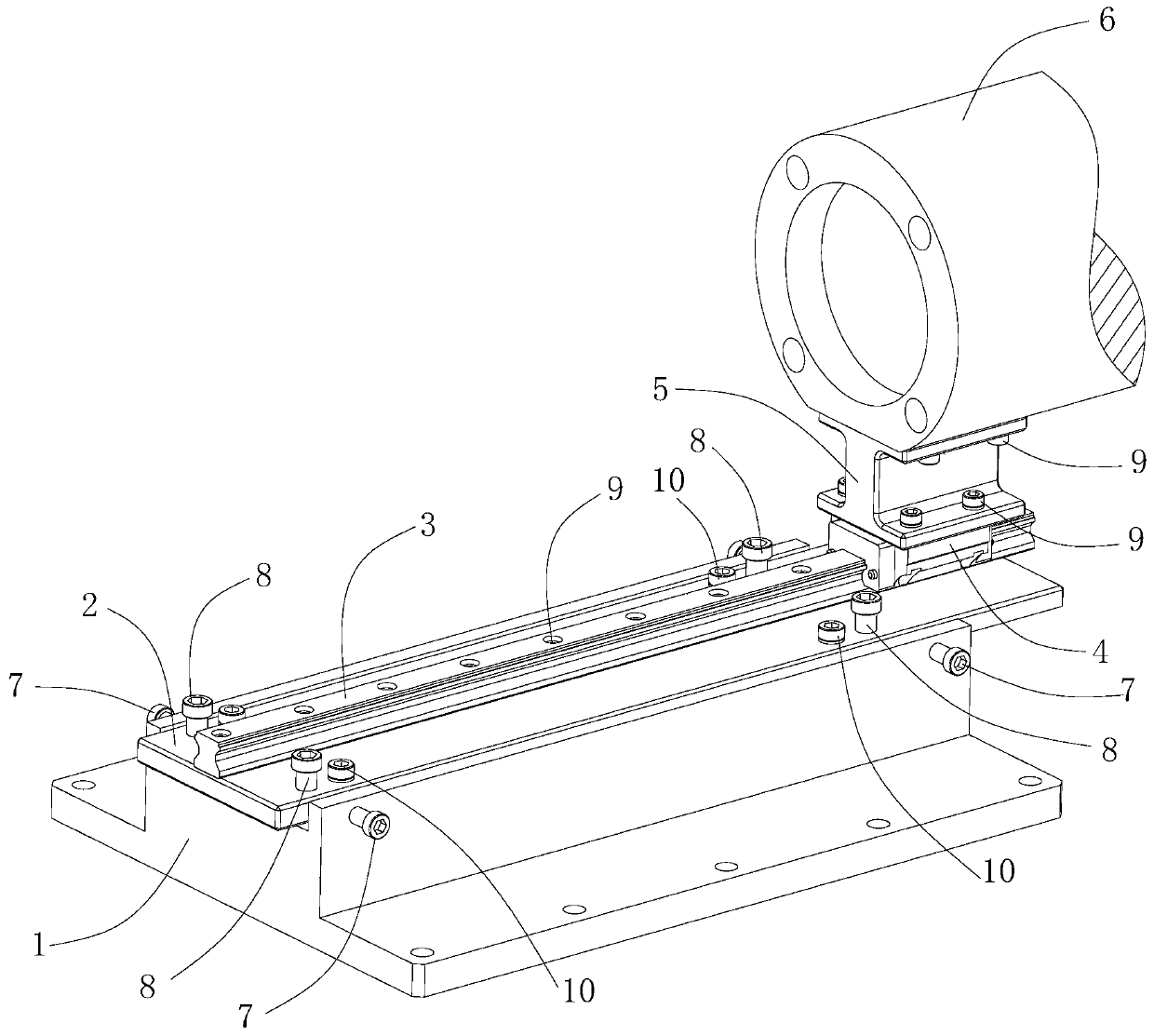

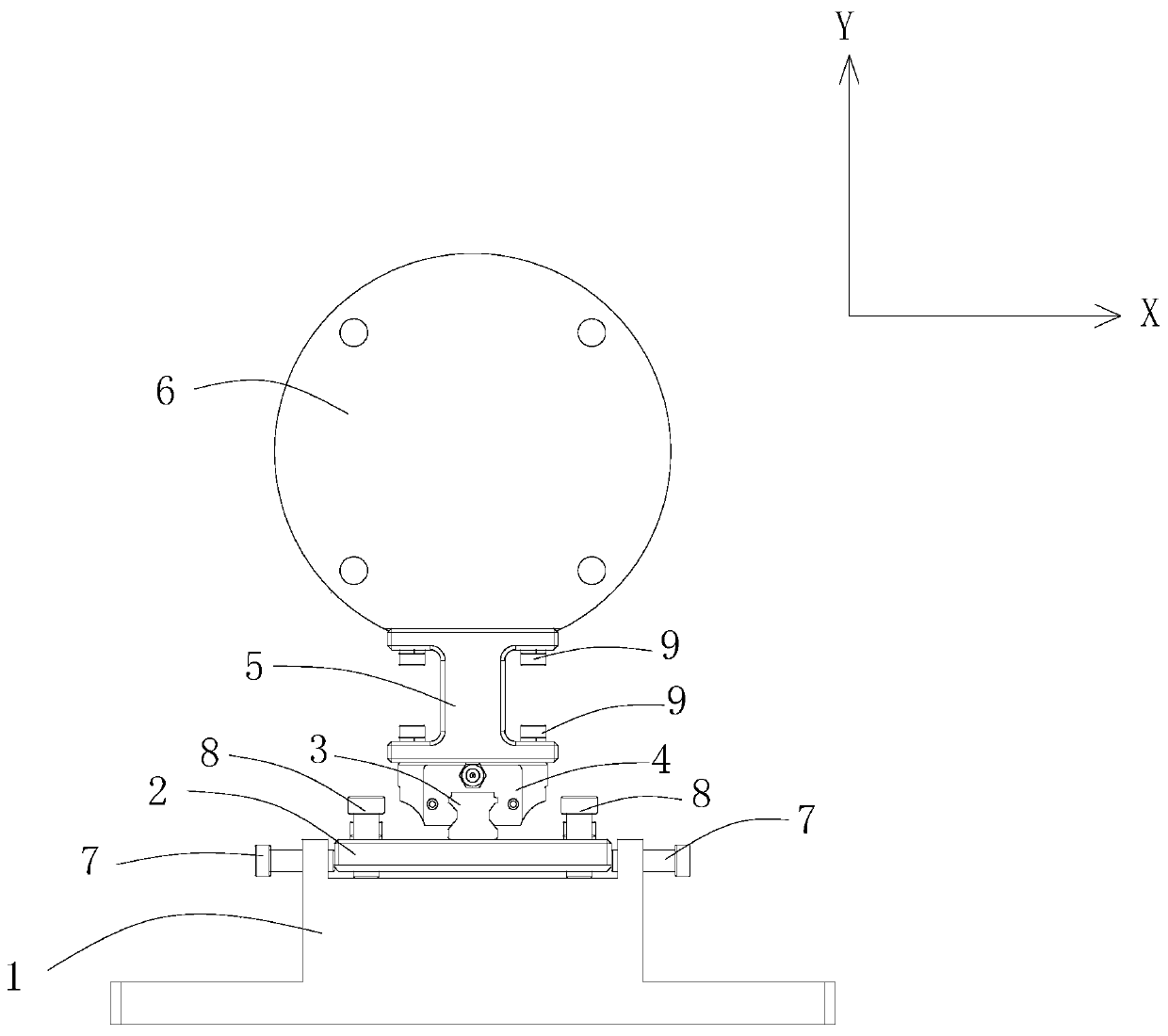

[0023] Embodiment 1: as Figure 1-3 The hydraulic cylinder piston rod adjustment device shown is placed directly below the free end of the piston rod 6 of the hydraulic cylinder. There is a boss, and an adjustment groove is opened on the boss, the adjustment plate 2 is embedded in the adjustment groove, the guide rail 3 is set on the adjustment plate 2, the support seat 5 is slidingly connected with the guide rail 3, and the support seat 5 can slide along the guide rail. The extension direction of 3 moves, the support seat 5 is used to connect with the piston rod 6, the adjustment assembly is respectively connected with the fixed seat 1 and the adjustment plate 2, and the adjustment assembly adjusts the position of the adjustment plate 2 in the adjustment groove, so that the support seat 5 and the adjustment plate The contact surface of the piston rod 6 is in a horizontal position, and the support seat 5 fixes the piston rod 6 and makes it in a horizontal position.

[0024] A...

Embodiment 2

[0034] Embodiment 2: as Figure 1-3 The hydraulic cylinder piston rod adjustment device shown is placed directly below the free end of the piston rod 6 of the hydraulic cylinder. There is a boss, and an adjustment groove is opened on the boss, the adjustment plate 2 is embedded in the adjustment groove, the guide rail 3 is set on the adjustment plate 2, the support seat 5 is slidingly connected with the guide rail 3, and the support seat 5 can slide along the guide rail. The extension direction of 3 moves, the support seat 5 is used to connect with the piston rod 6, the adjustment assembly is respectively connected with the fixed seat 1 and the adjustment plate 2, and the adjustment assembly adjusts the position of the adjustment plate 2 in the adjustment groove, so that the support seat 5 and the adjustment plate The contact surface of the piston rod 6 is in a horizontal position, and the support seat 5 fixes the piston rod 6 and makes it in a horizontal position.

[0035] A...

Embodiment 3

[0046] Embodiment 3: as Figure 1-3 The hydraulic cylinder piston rod adjustment device shown is placed directly below the free end of the piston rod 6 of the hydraulic cylinder. There is a boss, and an adjustment groove is opened on the boss, the adjustment plate 2 is embedded in the adjustment groove, the guide rail 3 is set on the adjustment plate 2, the support seat 5 is slidingly connected with the guide rail 3, and the support seat 5 can slide along the guide rail. The extension direction of 3 moves, the support seat 5 is used to connect with the piston rod 6, the adjustment assembly is respectively connected with the fixed seat 1 and the adjustment plate 2, and the adjustment assembly adjusts the position of the adjustment plate 2 in the adjustment groove, so that the support seat 5 and the adjustment plate The contact surface of the piston rod 6 is in a horizontal position, and the support seat 5 fixes the piston rod 6 and makes it in a horizontal position.

[0047] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com