High-temperature molten salt pump comprehensive test detection device and test method

A high-temperature molten salt, comprehensive test technology, used in pump control, non-variable-capacity pumps, machines/engines, etc., can solve the problem of not being able to meet the test requirements, unable to complete the valve test on the same stage, and unable to test the performance of high-temperature molten salt pumps And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

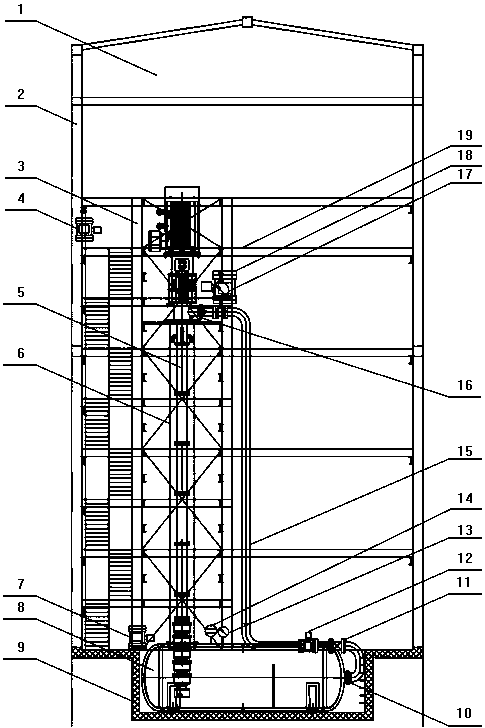

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail;

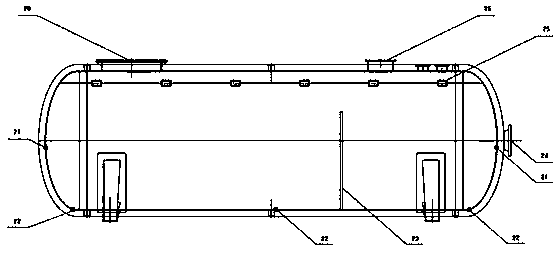

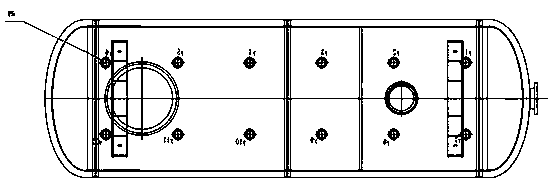

[0031] as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown; The specific method of the test is:

[0032]A comprehensive test and detection device for high-temperature molten salt pumps, including a test bench 1, a pump barrel 6, and a molten salt tank 8, characterized in that: the test bench 1 includes a frame 2, and several transverse supports 19 are arranged in the frame 2 , two test bench support steel frames 3 are longitudinally arranged; the bottom of the test bench 1 is provided with a molten salt tank tank 9, and a molten salt tank 8 is arranged in the molten salt tank tank tank 9; the upper surface of the molten salt tank 8 is The support bases for the heating pipes 25 inserted into the molten salt tank 8 are evenly distributed, and the molten salt pump insertion port 20, the liquid level gauge 14, the pressure transmitter 13 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com