Non-uniform transverse longitudinal groove turbine outer ring structure

A non-uniform, horizontal and vertical technology, applied in the direction of the stator, engine components, machine/engine, etc., can solve the problems of interfering with the normal and stable flow of the main flow of the blade cascade, the gas flow speed is fast, and the efficiency of the film cooling efficiency is reduced, so as to achieve the improvement Effects of film cooling efficiency, improved gas utilization efficiency, and improved cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

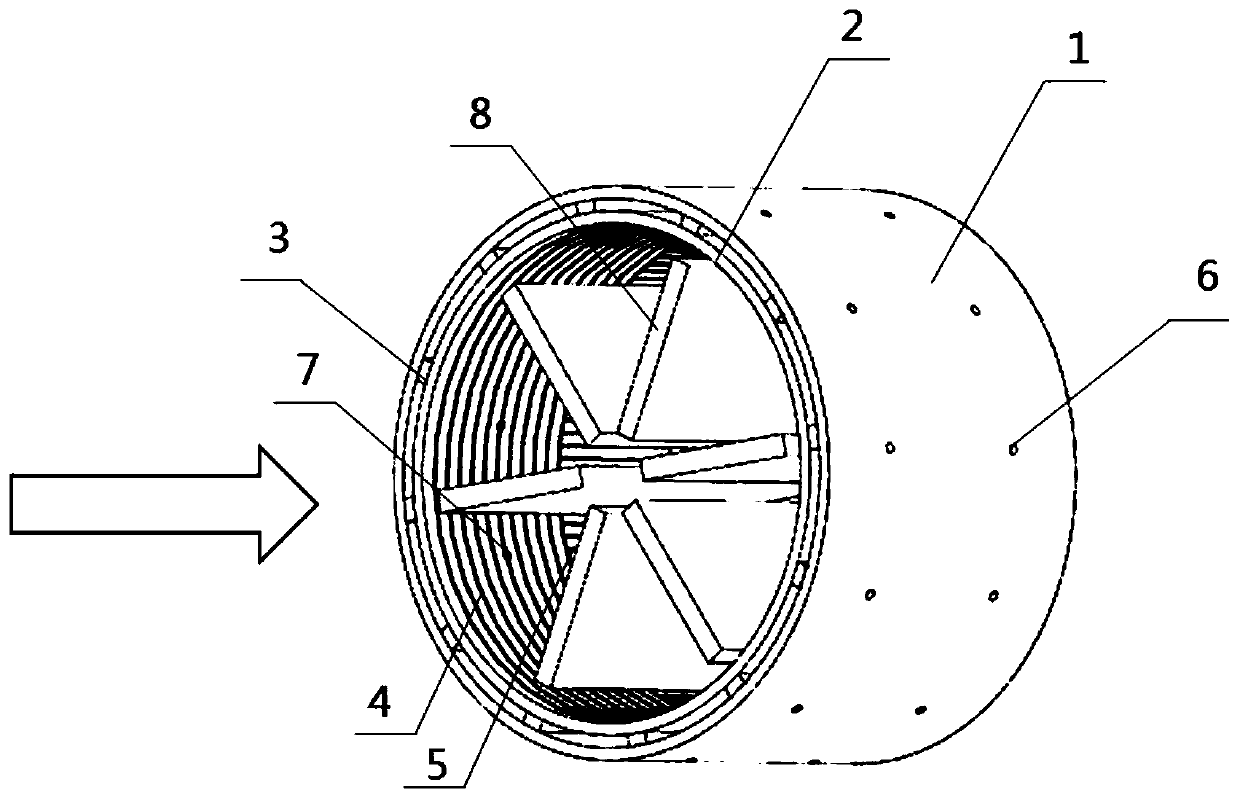

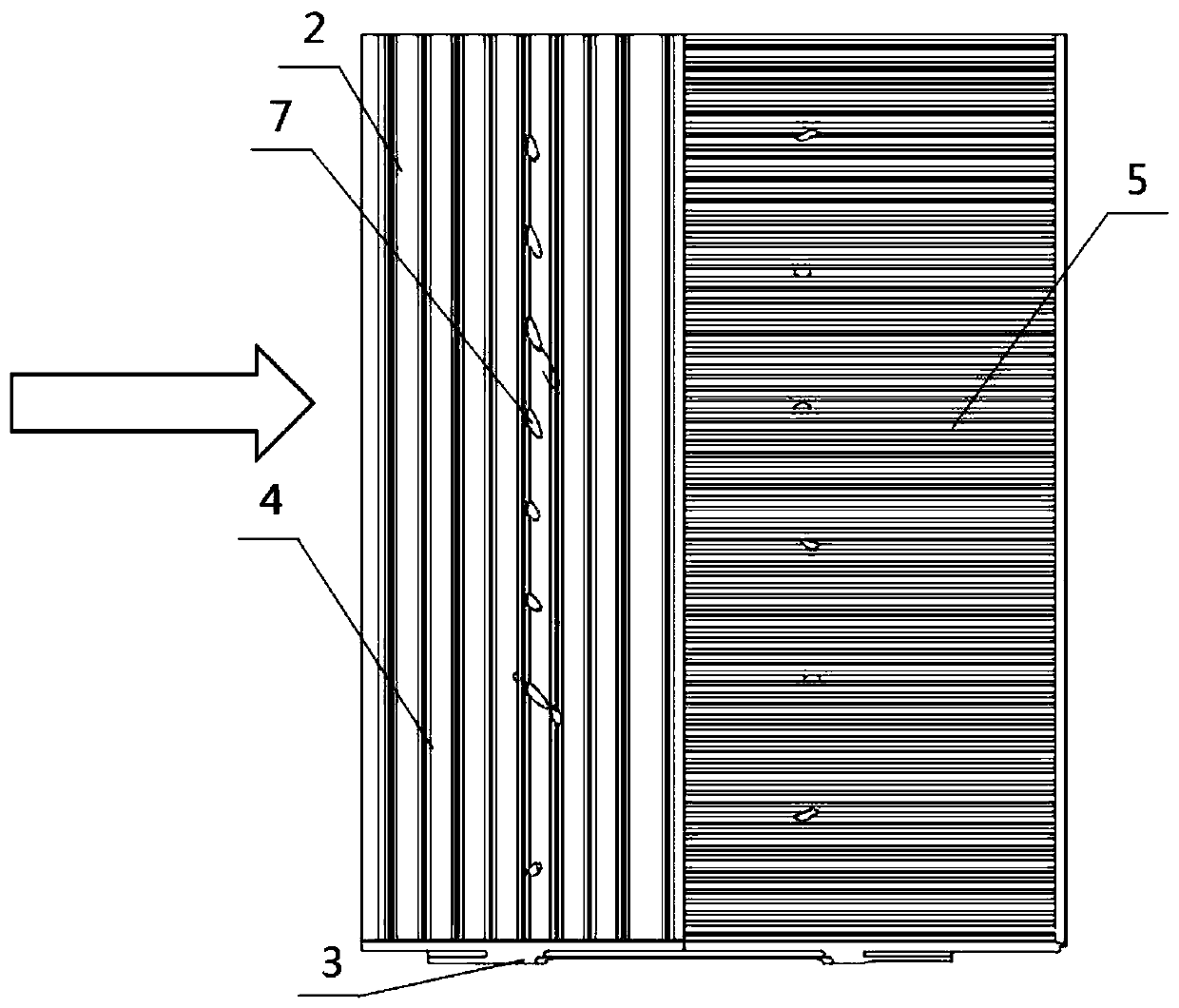

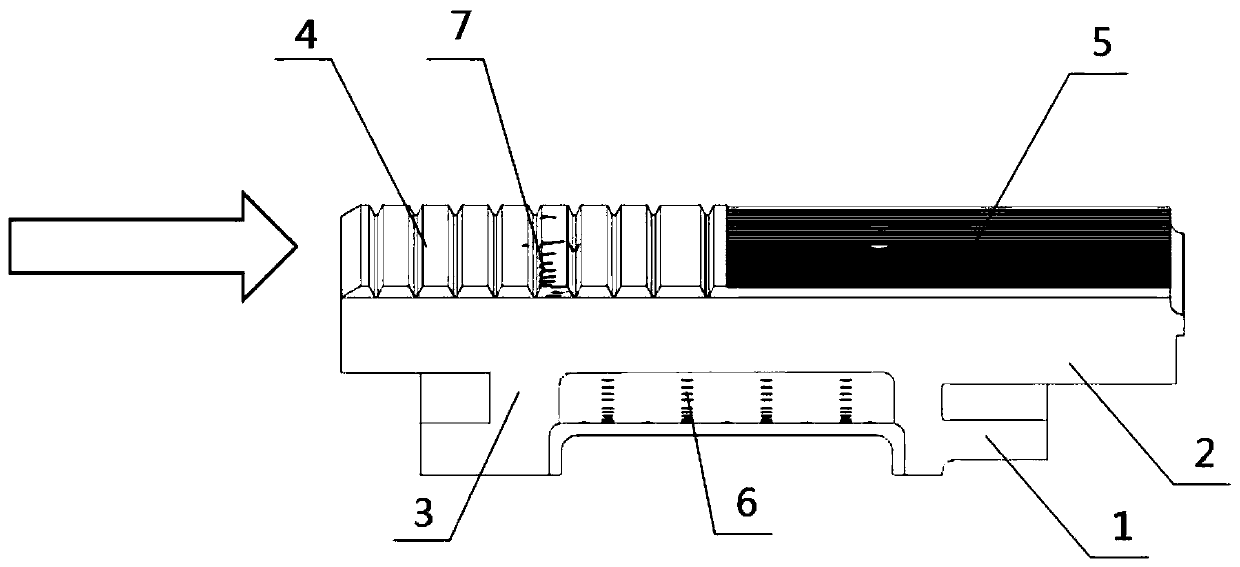

[0023] The axial chord length of the blade 8 is 40mm; the axial length of the outer casing 1 is 50mm, the thickness of the inner casing 2 and the outer casing 1 is 10mm, and the height of the connecting body 3 is 8mm; the inner diameter of the impact hole 6 is 0.8mm, two rows of impact holes 6, each row 30, evenly arranged, the impact angle of the impact hole 6 is 85°; the number of 3 connectors is 12, evenly arranged; two exhaust film holes 7, each exhaust film hole 7 is 30, and the air film hole is 7 The diameter is 0.5mm; the height of the circumferential rib groove 4 is 0.5mm, the gap between the rib grooves is 0.2mm, the width of the rib groove sealing tooth is 1.3mm, the chamfer of the top of the sealing tooth is 62.5°, and the overall length of the circumferential rib groove 4 is 25mm, evenly distributed on the inlet side of the cascade; the height of the axial rib groove 5 is 0.5mm, the width of the bottom of the rib groove is 0.2mm, the width of the rib groove sealing ...

Embodiment 2

[0026] The axial chord length of the blade 8 is 40 mm; the axial length of the outer shell 1 is 50 mm, the thickness of the inner shell 2 and the outer shell 1 is 10 mm, and the height of the connecting body 3 is 8 mm; the diameter of the impact hole 6 is 0.8 mm, and two rows of impact holes 6, each 25 rows, evenly arranged, the impact angle of the impact hole 6 is 90°; the number of 3 connectors is 20, evenly arranged; two exhaust film holes 7, each exhaust film hole 7 is 25, the air film The inner diameter of hole 7 is 0.5mm; the height of circumferential rib groove 4 is 0.5mm, the gap between rib grooves is 0.2mm, the width of rib groove sealing teeth is 0.6mm, the chamfer of the tooth top of sealing teeth is 62.5°, and the circumferential rib groove 4 The overall length is 20mm, evenly distributed on the inlet side of the cascade; the height of the axial rib groove 5 is 0.5mm, the width of the bottom of the rib groove is 0.2mm, the width of the rib groove sealing teeth is 0...

Embodiment 3

[0029]The axial chord length of the blade 8 is 40 mm; the axial length of the outer shell 1 is 50 mm, the thickness of the inner shell 2 and the outer shell 1 is 10 mm, and the height of the connecting body 3 is 8 mm; the inner diameter of the impact hole 6 is 0.8 mm, and two rows of impact holes 6, each There are 25 rows, evenly arranged, and the impact angle of the impact hole 6 is 80°; the number of 3 connectors is 20, evenly arranged; two exhaust membrane holes 7, each exhaust membrane hole 7 is 30, and the air membrane The inner diameter of the hole 7 is 0.5mm; the height of the circumferential rib groove 4 is 0.5mm, the rib groove gap is 0.2mm, and the width of the rib groove sealing teeth is different. mm, increasing successively toward the outlet of the cascade. The top chamfer of the sealing tooth is 62.5°, the overall length of the circumferential rib groove 4 is 30mm, and is unevenly distributed on the inlet side of the cascade; the height of the axial rib groove 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com