Multi-cavity sectional type descending gas extracting, drilling and water draining device and method

A gas drainage and drainage device technology, which is applied in the direction of gas discharge, drainage, safety devices, etc., can solve the problems of poor gas drainage effect, inability to realize deep hole drainage, limited drainage depth, etc., and achieve convenient disassembly and repetition Use and avoid the effect of limited drainage depth and convenient drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

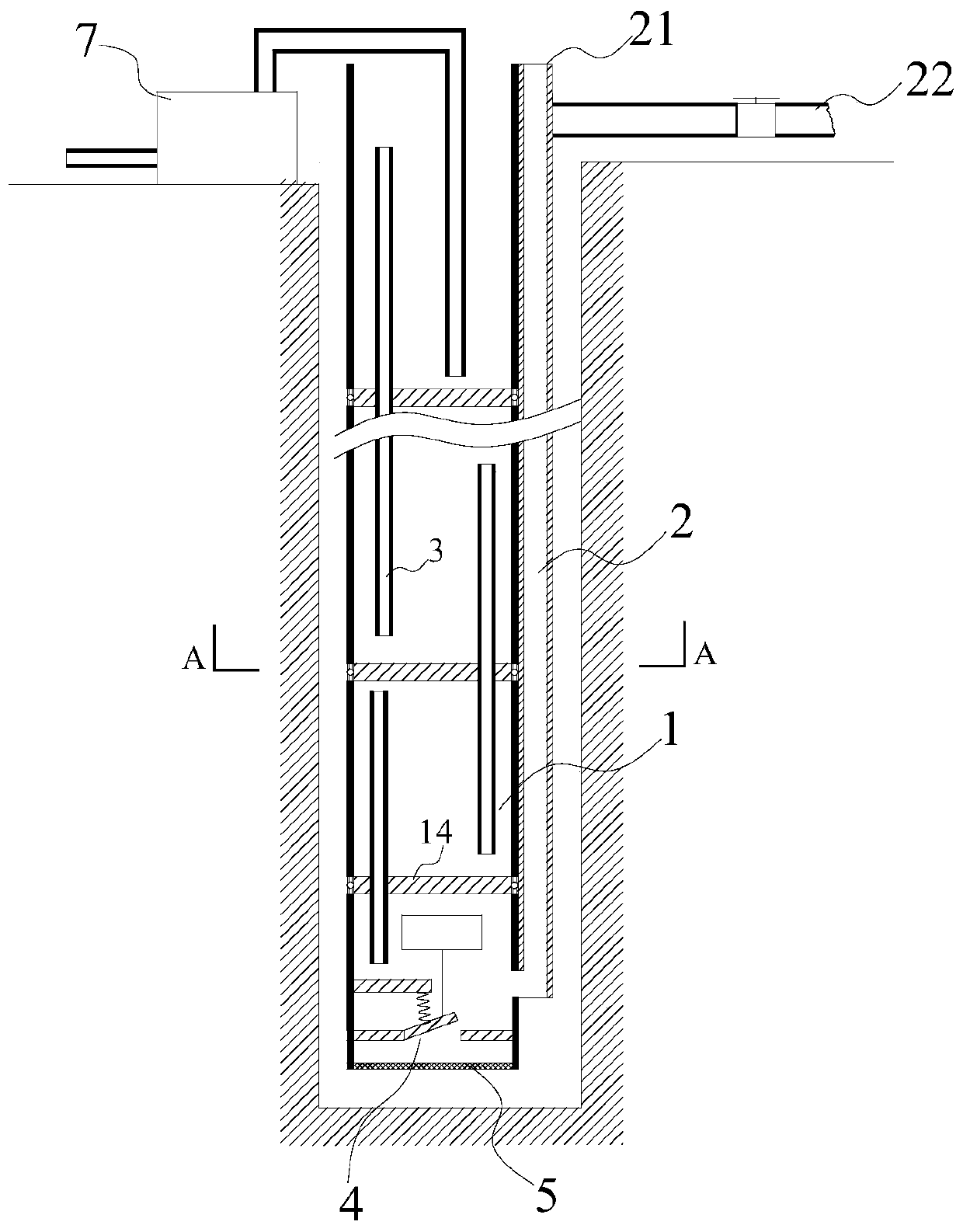

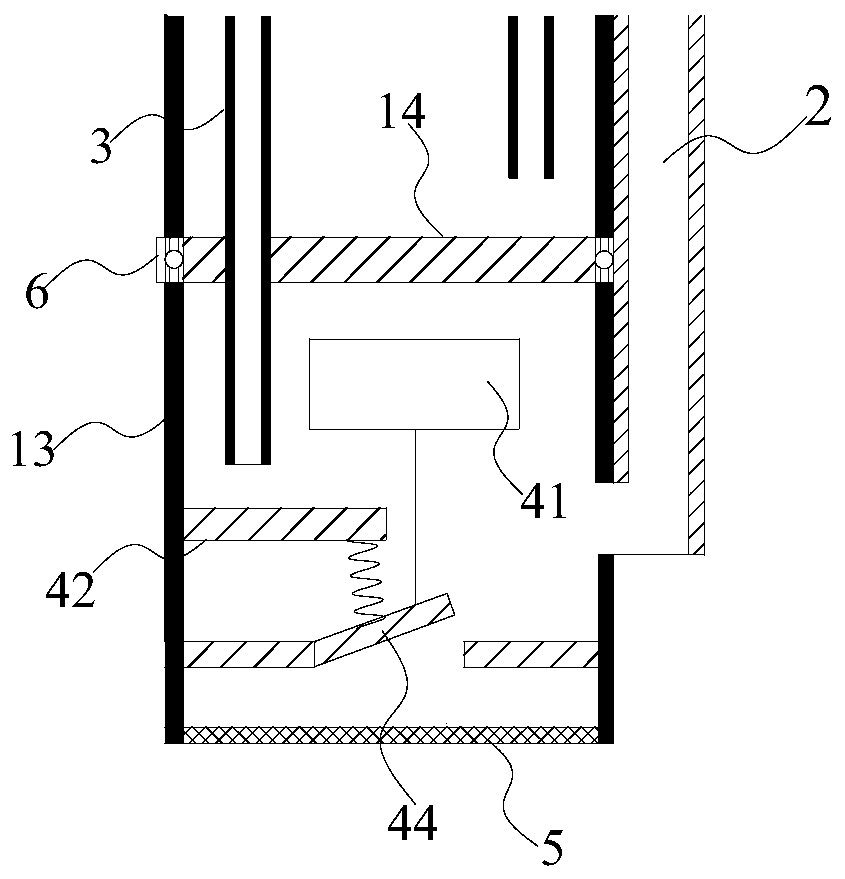

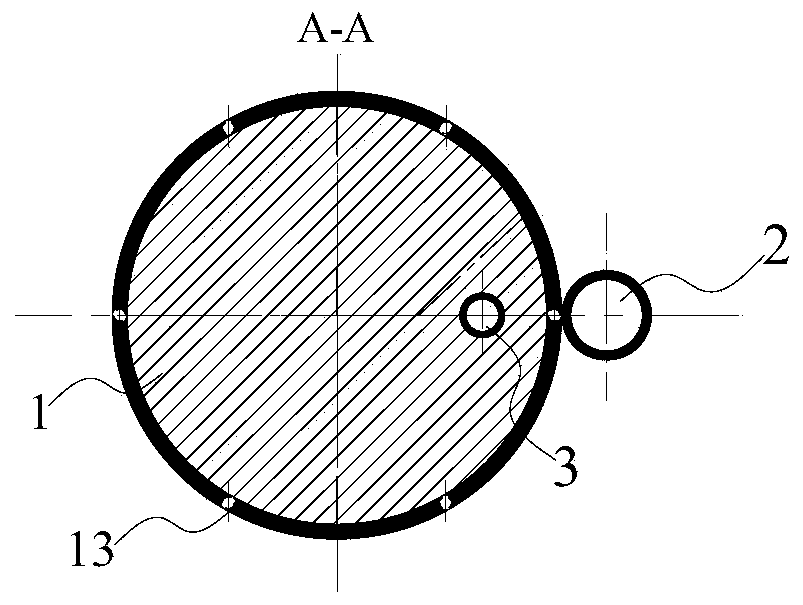

[0029] A specific structure of a multi-cavity segmented downward gas drainage borehole drainage device includes a plurality of segmented chambers 1, a gas injection pipe 2, a water conduit 3, and a float valve 4. The multiple segmented chambers 1 divide the downward long borehole into multiple stages, and the distance of each stage is respectively injected and drained, so that the injection pressure does not need to be large to meet the requirements. The segmented chamber 1 includes a connecting pipe 13 and a segmented partition 14, a plurality of segmented chambers 1 are connected in sequence, the water pipe 3 is connected to the adjacent segmented chamber 1, and the gas injection pipe 2 is connected to the bottom of the hole segmented chamber 1 , A float valve 4 and a filter screen 5 are also provided in the segmented cavity 1 at the bottom of the hole. The device is provided with a plurality of segmented chambers 1, which solves the technical problem that the compressed air ...

Embodiment 2

[0040] The specific structure of the multi-cavity segmented downward gas drainage borehole drainage device includes a plurality of segmented chambers 1, a gas injection pipe 2, a water conduit 3 and a float valve 4. Among them, the gas drainage boreholes are arranged downwards and drilled vertically or obliquely downwards. The multiple segmented chambers 1 divide the downward long boreholes into multiple stages. The segmented chamber 1 includes a connecting pipe 13 and a segmented partition. Plate 14, multiple segmented chambers 1 are connected in sequence, so as to be placed in the downward gas drainage borehole, water pipe 3 is connected to each adjacent segmented chamber 1, and gas injection pipe is connected to the bottom segmented cavity of the through hole. In the chamber 11, a float valve 4 and a filter screen 5 are also arranged in the hole bottom segmented chamber 11, which are used to control the water intake in the device and prevent the device from being blocked.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com