Assembly type waterproof double-layer circle-type non-node underground comprehensive pipe gallery

A comprehensive pipe gallery and prefabricated technology, applied to underwater structures, water conservancy projects, protection devices, etc., can solve the problems of poor integrity of underground comprehensive pipe gallery, time-consuming and labor-intensive installation, and unstable structure, etc., to achieve novel waterproof measures, The pipe gallery body is firm and the construction is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

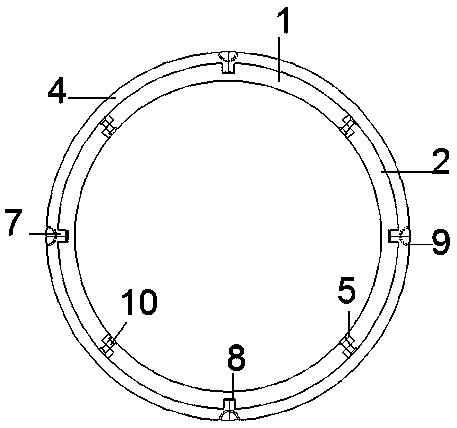

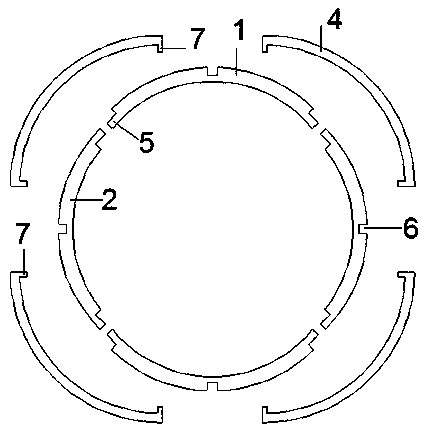

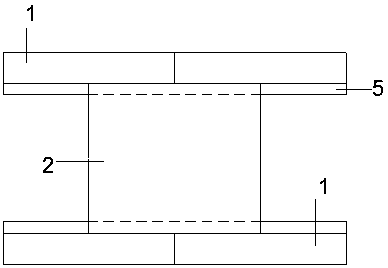

[0023] Embodiment 1: as figure 1 As shown in -7, an assembled waterproof double-layer circular node-free underground comprehensive pipe gallery of the present invention includes arc-shaped pipe gallery wall one 1, arc-shaped pipe gallery wall two 2, end pipe gallery wall 3, and arc-shaped concrete Outer shell 4, pipe gallery body connecting rib 5, gallery wall groove 6, shell connecting rib 7, waterproof rubber cushion 8, U-shaped bolt 9, high-strength bolt 10, reserved bolt hole 11, U-shaped bolt hole 13, its characteristics It is that: the arc-shaped pipe gallery wall 1 and the arc-shaped pipe gallery wall 2 are symmetrically arranged on the upper and lower sides and the left and right sides of the comprehensive pipe gallery, respectively, to form the inner pipe gallery wall, which is circular in shape and arc-shaped. The positions of the pipe gallery body connecting ribs 5 on the arc-shaped pipe gallery wall 1 and the arc-shaped pipe gallery wall 2 are corresponding, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com