Pyrolysis stirring apparatus for treating contaminated soil

A technology of polluted soil and stirring device, which is applied in the field of stirring device, can solve the problems affecting the quality of soil treatment, uneven heating of soil, incomplete pyrolysis, etc., to improve the efficiency and quality of pyrolysis, and the soil is fully heated and heated Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

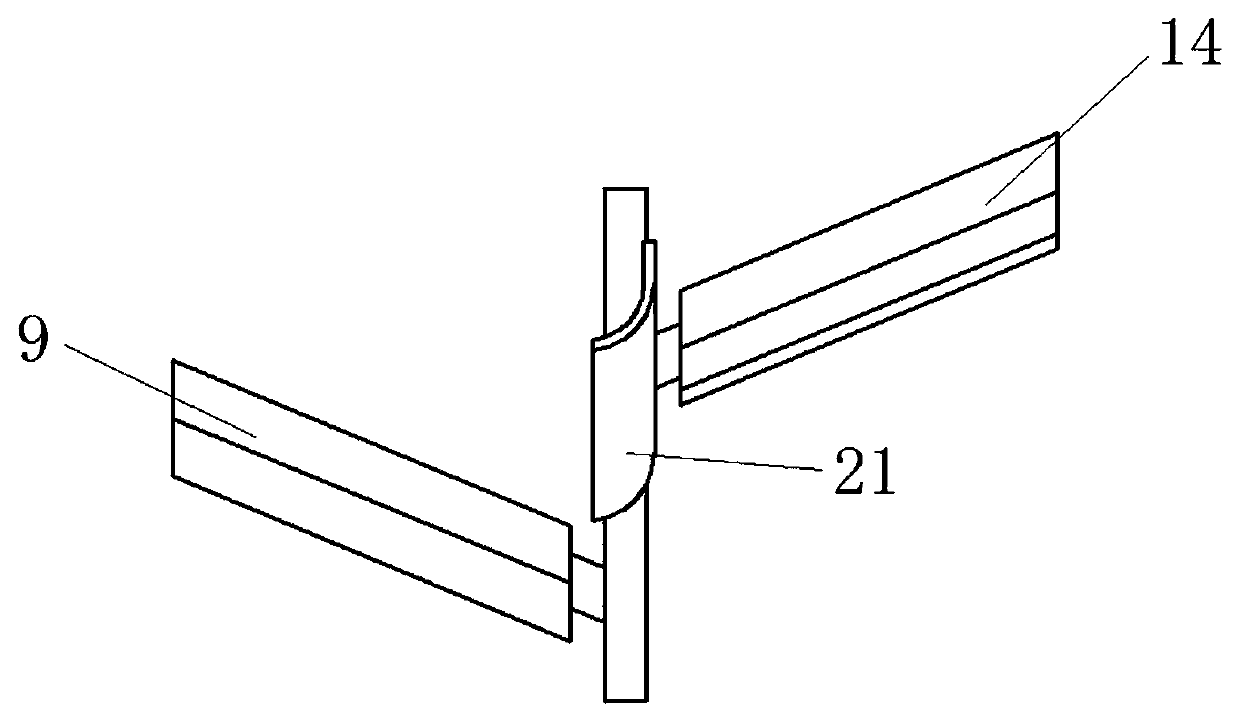

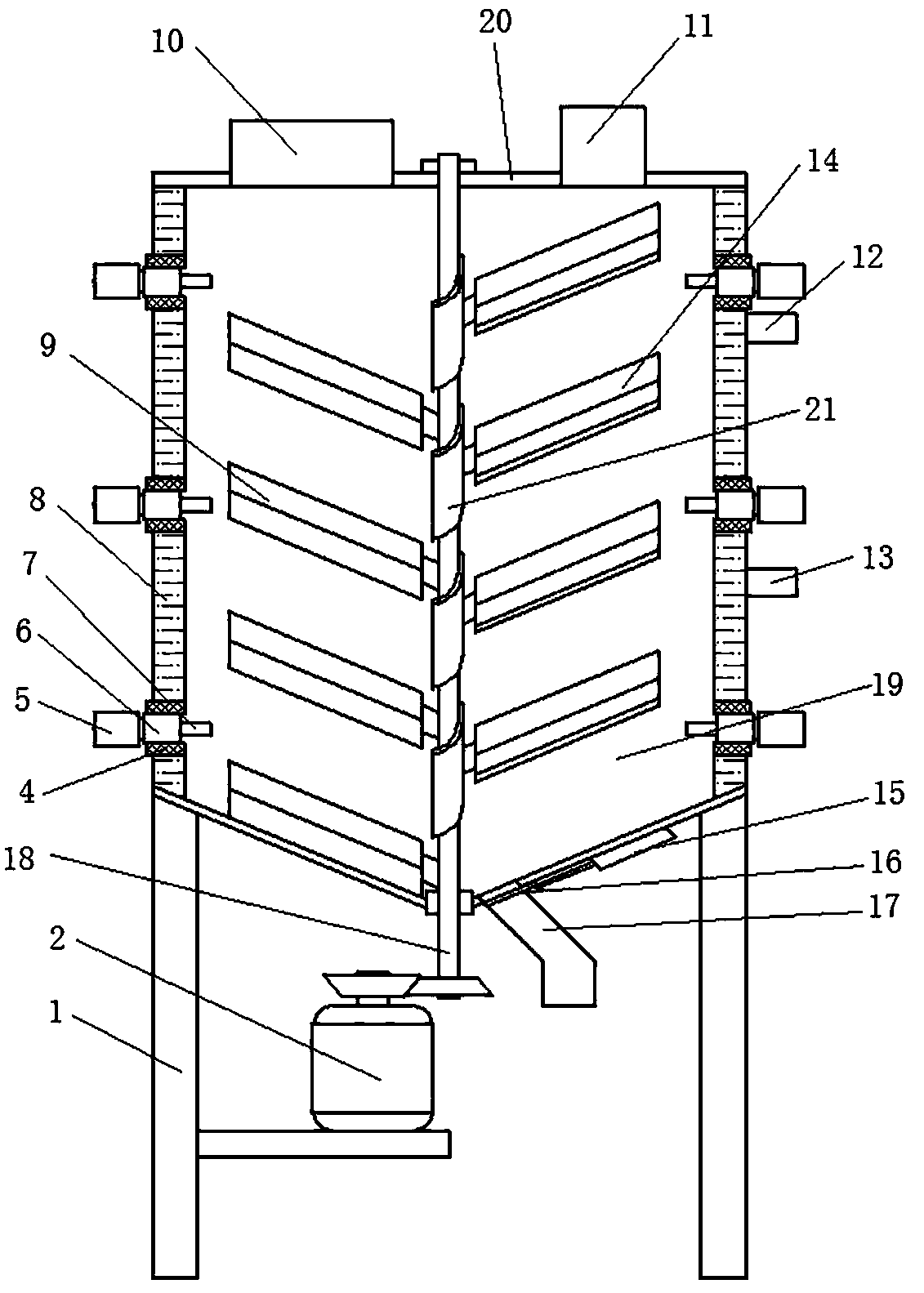

[0025] Such as Figure 1-2 As shown, a pyrolysis tank 19 is welded on the frame 1, and a top cover 20 is connected by bolts on the top of the pyrolysis tank 19, and a feed inlet 10 and an exhaust port 11 are welded on the top cover 20. A jacket 8 is arranged on the outside of the side wall of the pyrolysis tank 19, an oil inlet 13 and an oil outlet 12 are arranged on the jacket 8, and a group of ultrasonic vibration components are arranged on the side wall of the pyrolysis tank 19. The heat insulation bushing 4 that is threaded on the side wall of the pyrolysis tank 19 and runs through the side wall is threaded on the heat insulation bush 4 and the ultrasonic horn 6 and the tool head 7 fixed at one end of the ultrasonic horn 6, An ultrasonic transducer 5 is fixed at the other end of the ultrasonic horn 6 , the tool head 7 is located inside the pyrolysis tank 19 , and the ultrasonic transducer 5 is located outside the pyrolysis tank 19 .

[0026] The bottom of the pyrolysis ta...

Embodiment 2

[0029] Such as Figure 2-3 Shown, different from embodiment 1 is:

[0030] Three groups of ultrasonic vibration components are arranged on the side wall of the pyrolysis tank 19 .

[0031] Other content is identical with embodiment 1.

[0032] The working principle of the present invention is: heat the heat-conducting oil to the set temperature by the external heat-conducting oil furnace, pass the heat-conducting oil into the jacket 8 from the oil inlet 13, and flow back into the heat-conducting oil furnace from the oil outlet 12. Open the external ultrasonic generator through external control, open the stirring motor 2, and the cylinder 15 is connected to the external air source and stretched out, so that the material blocking plate 16 closes the discharge pipe 17. The polluted soil is sent into the pyrolysis tank 19 from the feed inlet 10, and the polluted soil is constantly stirred in the thermal pyrolysis pipe 19, due to the first stirring paddle 9, the second stirring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com