Mobile socket and cover plate used thereon

A socket and cover technology, applied in the base/housing, parts of the connection device, electrical components, etc., can solve the problems of dirty surface of the socket, cannot be washed with water, potential safety hazards, etc., and achieve the effect of reducing production cost and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

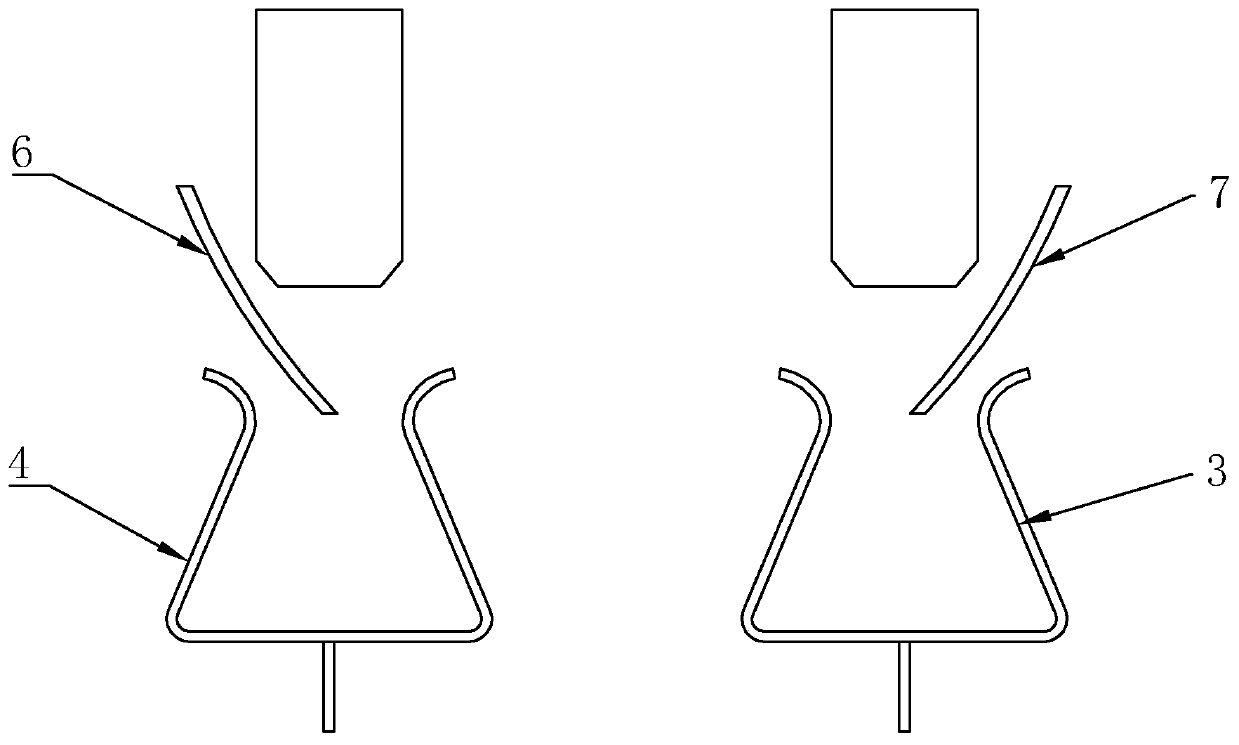

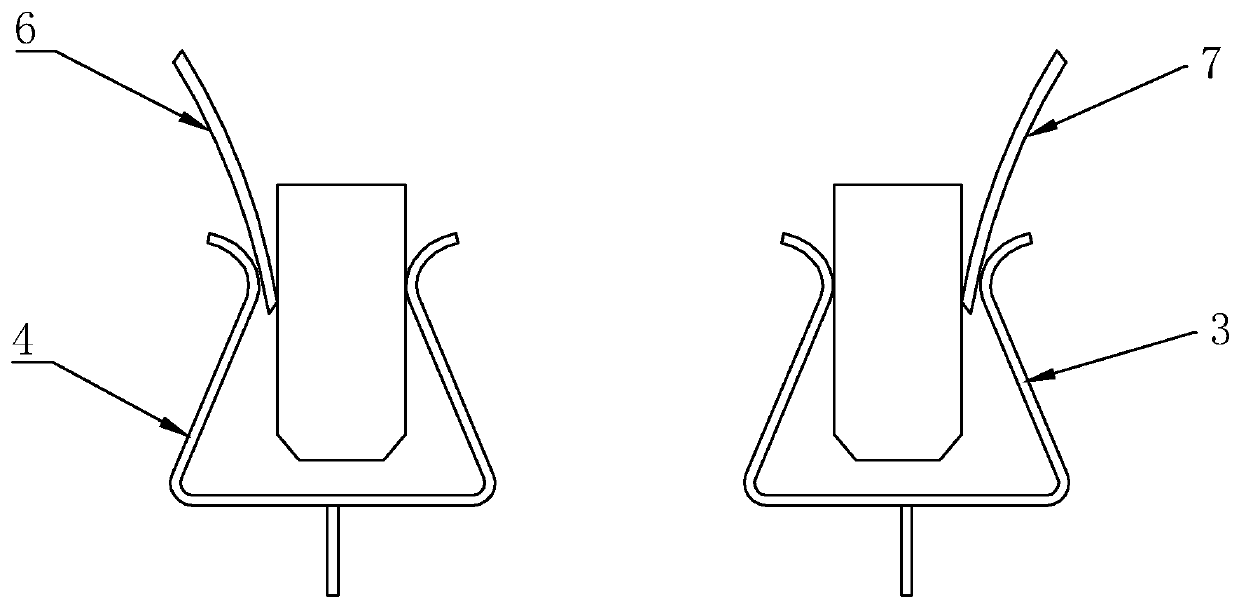

[0050] The spring sets the other end of the safety door opposite to the wedge-shaped surface. This end is provided with a groove for placing the spring, and the center of the bottom of the groove is provided with a positioning post.

[0051] The groove cooperates with the positioning post to make the connection between the spring and the safety door more firm, and prevent the spring from colliding with the safety door in the state of elastic compression, so as to avoid affecting the normal reset of Ah Quan. A spring is installed at the corresponding position of each safety door to reset the safety door The effect is better.

Embodiment 2

[0053] The spring is arranged at the intersection position of the positive clamping plate 15 and the negative clamping plate 16 .

[0054] Reduce the number of springs and reduce production costs.

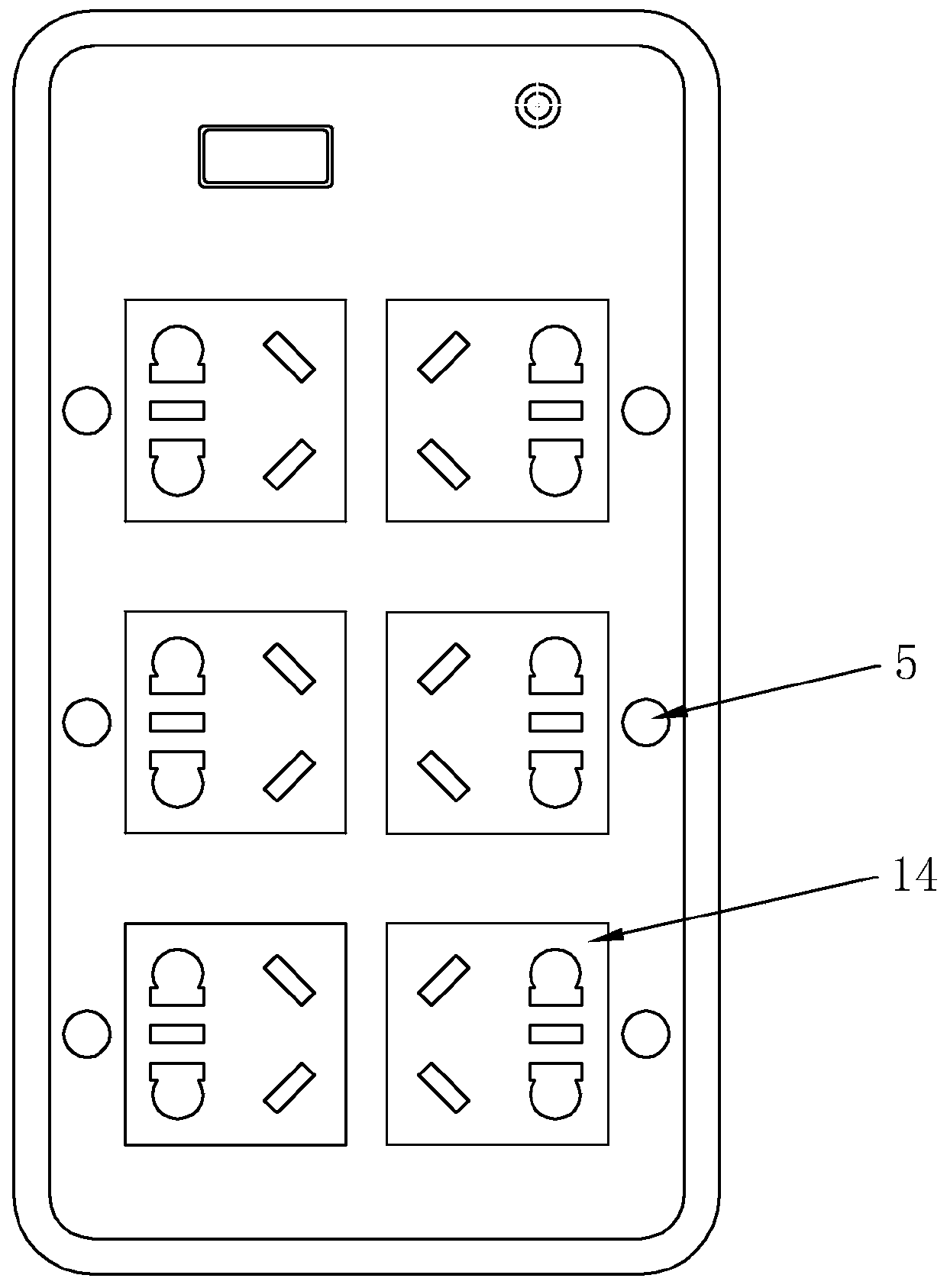

[0055] according to Image 6 As shown, the mobile socket can be split or used together. The bottom box 1 is divided into a main bottom box and a secondary bottom box, and the panel 2 is divided into a main panel and a secondary panel. The main bottom box and the main panel are spliced to form the main socket 11, and The main chamber is formed, the auxiliary bottom box and the auxiliary panel form the auxiliary panel, and the auxiliary chamber is formed, the main socket 11 and the auxiliary socket 12 are detachably and fixedly connected, and the end surface of the main socket 11 opposite to the auxiliary socket 12 is provided with a female terminal. The socket 12 is provided with a male lug on the end face relative to the main socket 11, and the male lug is coupled with the femal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com