Novel automatic lifting nitrogen blowing instrument

A technology of automatic lifting and nitrogen blowing instrument, used in instruments, scientific instruments, sampling and other directions, can solve the problems of inconvenient, inconvenient, artificial loosening of the height adjustment of the blowing pipe, saving labor costs, simple structure, and stable lifting control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

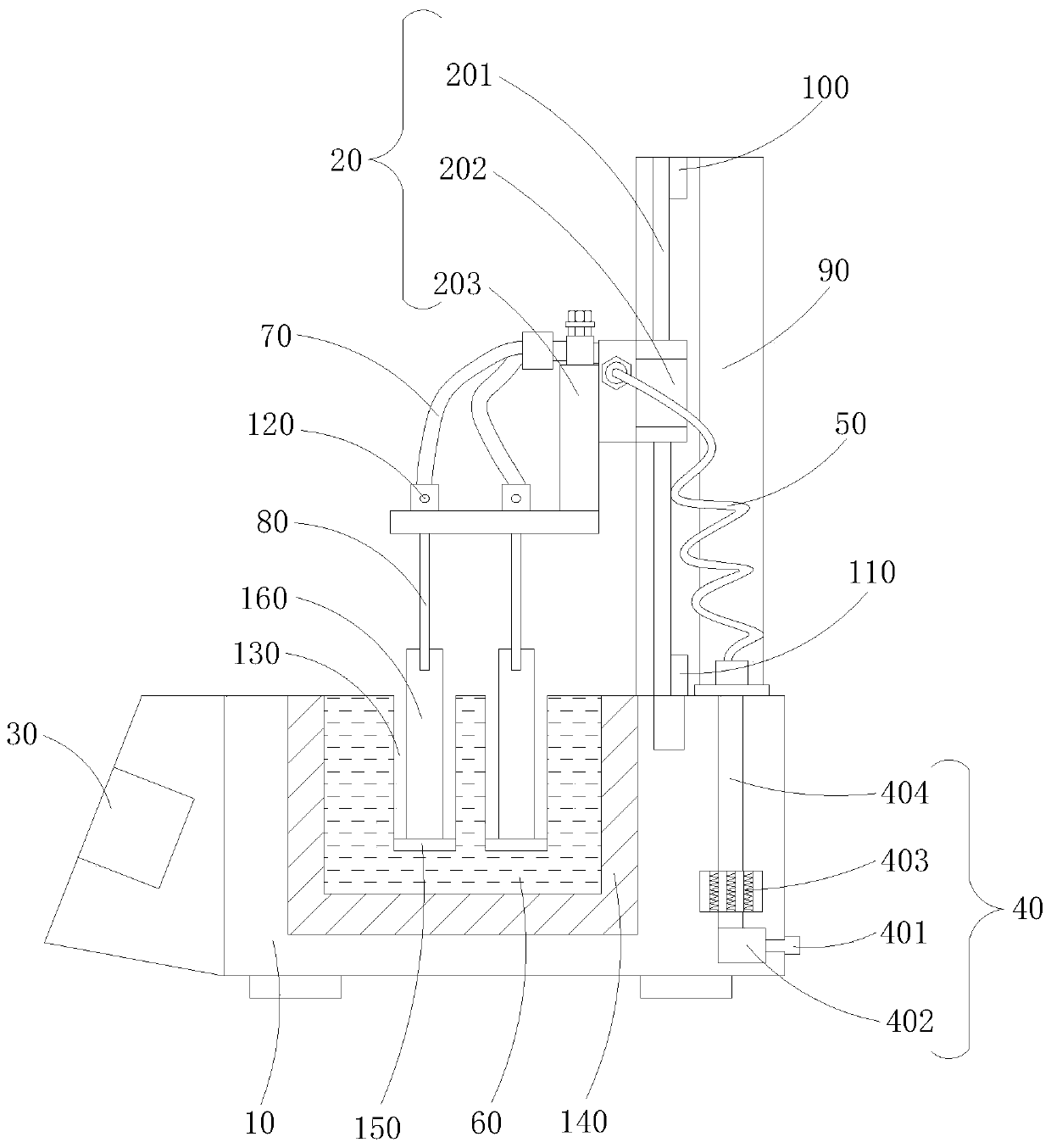

[0026] refer to figure 1 , in the embodiment of the present invention, a new type of automatic lifting nitrogen blowing instrument includes a base 1, a control panel 30 is installed on the side of the base 1, the control panel 30 is electrically connected to the electric slider 202 through a wire, and the control panel 30 sends out Instructions control the sliding of the electric slider 202. The upper end of the base 1 is provided with a heating pool 60, the right side of the base 1 is equipped with a preheating device 40, and the right side of the upper end of the base 1 is connected with a lifting device 20 through a bracket 90. The device 20 includes an electric slider 202, a linear guide rail 201 and a lifting plate 203. The electric slider 202 is sleeved on the linear guide rail 201 and moves longitudinally along the linear guide rail 201. The electric slider 202 is connected with the lifting plate 203. The lifting plate 203 is also provided with a nitrogen blowpipe 70 an...

Embodiment 2

[0033] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the heating pool 60 is made of high temperature resistant glass material, and a groove 130 is opened in the heating pool 60 for heating Pool 60 periphery is provided with heat insulation layer 140, and described groove 130 interior is provided with test tube 160, and groove 130 bottom is provided with gasket 150, and this gasket 140 is used for preventing the test tube 160 in groove 130 from contacting with the bottom of groove 130. Collision damage, its function of heating pool 60 is exactly to fix test tube 160 and conduct heat, and heating pool 60 adopts high temperature resistant glass material to be convenient to observe the change of the sample in test tube 160 simultaneously; Heat from the heating pool 60 is dissipated.

[0034]The working principle of the present invention is: when in use, the sample to be concentrated is first packed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com