Tectonic coal block type briquette coal triaxial sample preparation device and method with controllable apparent density

A technology of apparent density and tectonic coal, applied in the field of briquette pressing, can solve the problems of sample pressing failure, experimental error, uneven stress distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

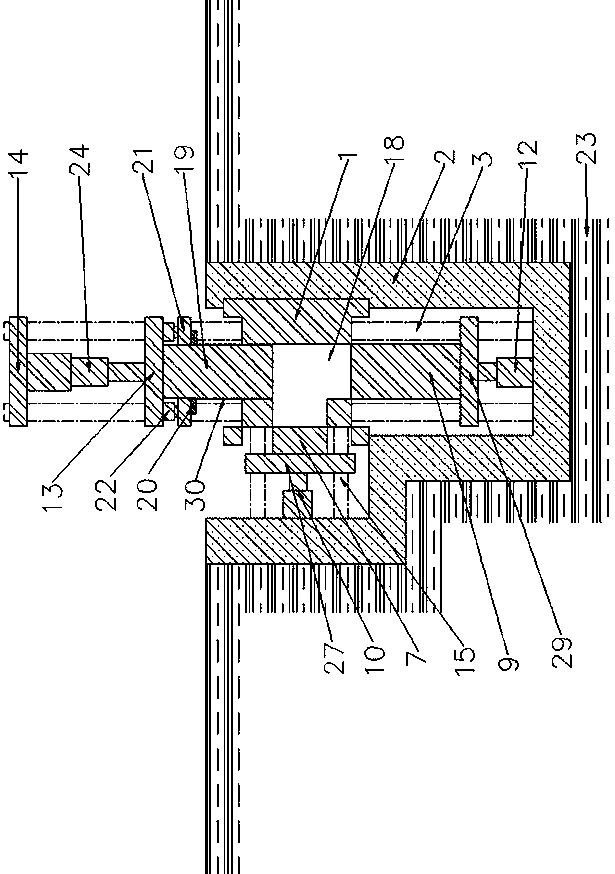

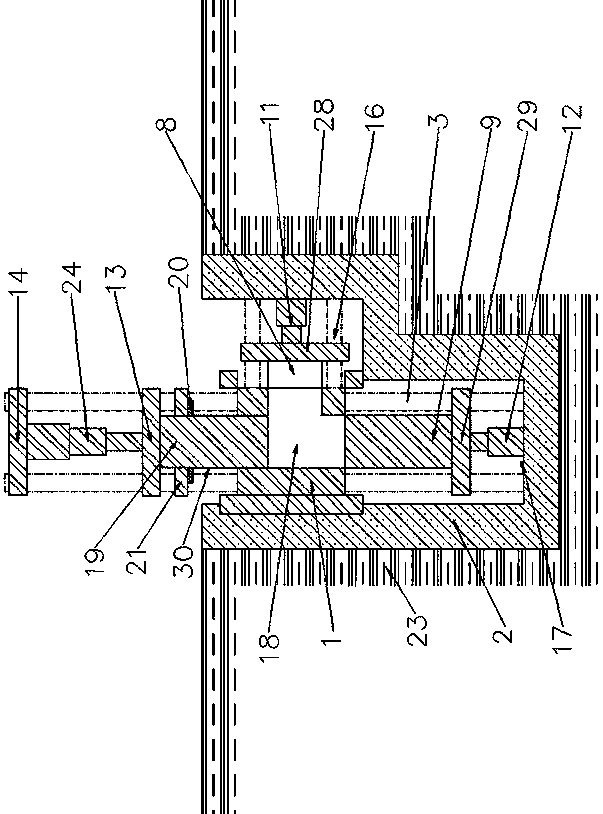

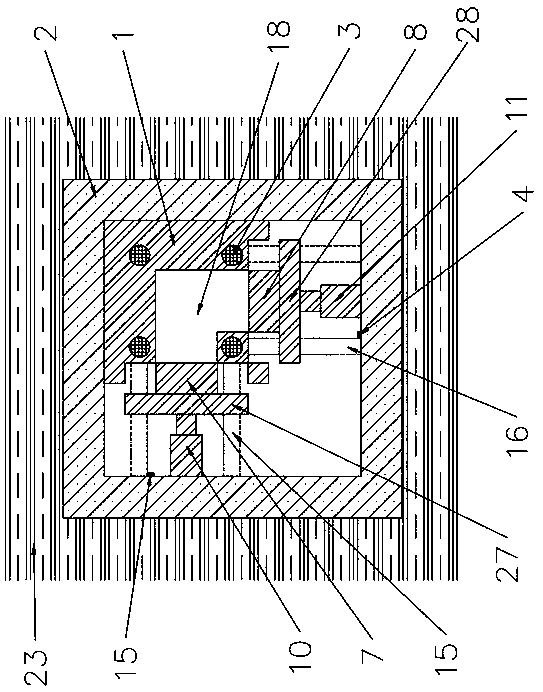

[0039] Such as Figure 1-Figure 4 As shown, the controllable apparent density structural coal block-shaped coal triaxial sample preparation device of the present invention includes a concrete fixing tank 2 with an open top, and four load-bearing beams arranged in a rectangular array are pre-embedded in the bottom of the concrete fixing tank 2. Column 3, the upper ends of four load-bearing columns 3 protrude from the concrete fixing groove 2 and a fixing plate 14 is horizontally arranged;

[0040] The upper part of the concrete fixing groove 2 is provided with a molding box 1 which is in the shape of a cuboid as a whole. 3 vertically pass through the side wall of the molding box 1 and be fixedly connected with the molding box 1, the top, bottom, left side and front side of the molding box 1 are provided with a rectangular hole, the pressure inside the molding box 1 The cross-section of the mold cavity 18, the rectangular hole at the top and the rectangular hole at the bottom a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com