Test platform and method of nonparallelism of space ring on coupling influence rule of main shaft thermal structure

A technology for testing platform and parallelism, which is applied in the field of machinery, can solve problems such as poor parallelism of the end face of the spacer, preload force, bearing running performance, influence of heat generated by contact load, lack of influence of bearing performance on the geometric accuracy of the end face of the spacer, etc., to achieve The effect of simple structure and clear test principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

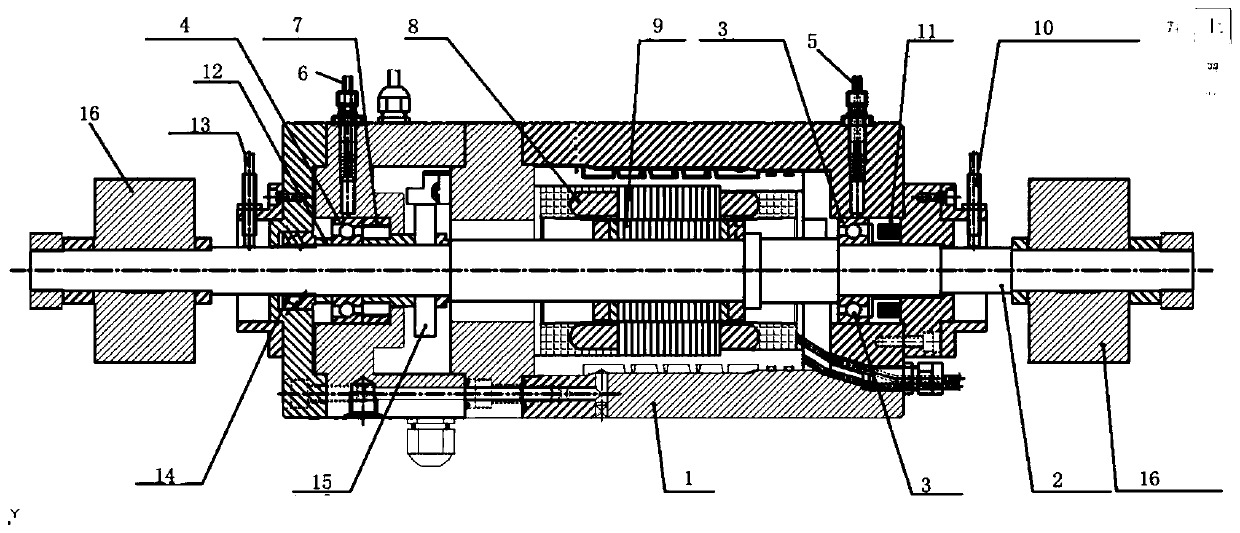

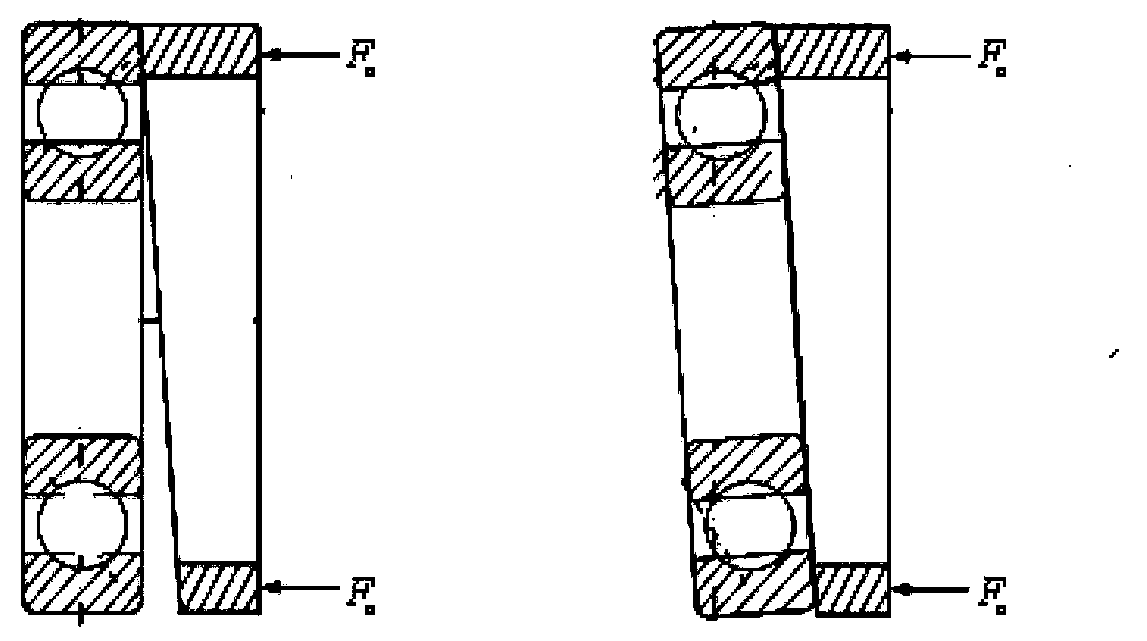

[0043] In Example 1, a fixed rotational speed was set, and five spacers with different parallelisms were used for comparative tests. Table 1 shows the spacers and spindle speeds used.

[0044] Table 1 Example 1 spacer and tachometer

[0045]

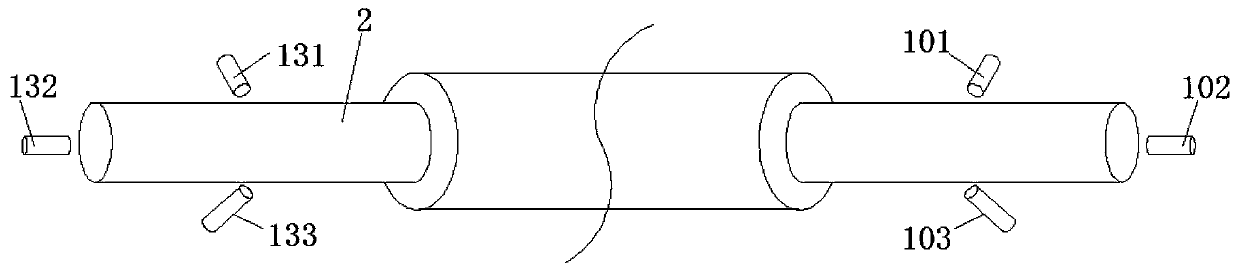

[0046] The temperature of the spacer ring changes with time as shown in the figure Figure 5 As shown, the thermal elongation of the main shaft 2 in the three directions of X, Y and Z is as follows Image 6 , 7 , 8 shown.

Embodiment 2

[0048] Example 2 The temperature rise characteristics of the spindle at different rotational speeds (1000-8000 rpm) were measured, and it was operated continuously. The display screen of the industrial computer records the temperature rising trend of each measurement point in real time, and records the temperature value every 2s until the shaft system reaches thermal equilibrium at this speed, and then increases the speed to continue the operation measurement.

[0049] Under the condition of variable speed, the set spacer non-parallelism error and speed are shown in Table 2.

[0050] Table 2 Example 2 Spacer and tachometer

[0051]

[0052] Under the condition of variable speed, the temperature of the spacer ring with a single parallelism error changes with time as follows: Figure 9 shown.

[0053] Under the condition of variable speed, the thermal elongation of the spindle is as follows Figure 10 shown.

[0054] according to Figure 6-8 and Figure 10 Analysis show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com