Heat pipe and heat exchanger

A technology of heat exchangers and heat pipes, which is applied in the field of heat exchangers and heat pipes, can solve the problems of prone to bursting, increasing the pressure of the water tank, and bursting of the water tank, and achieve the effect of saving the water tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

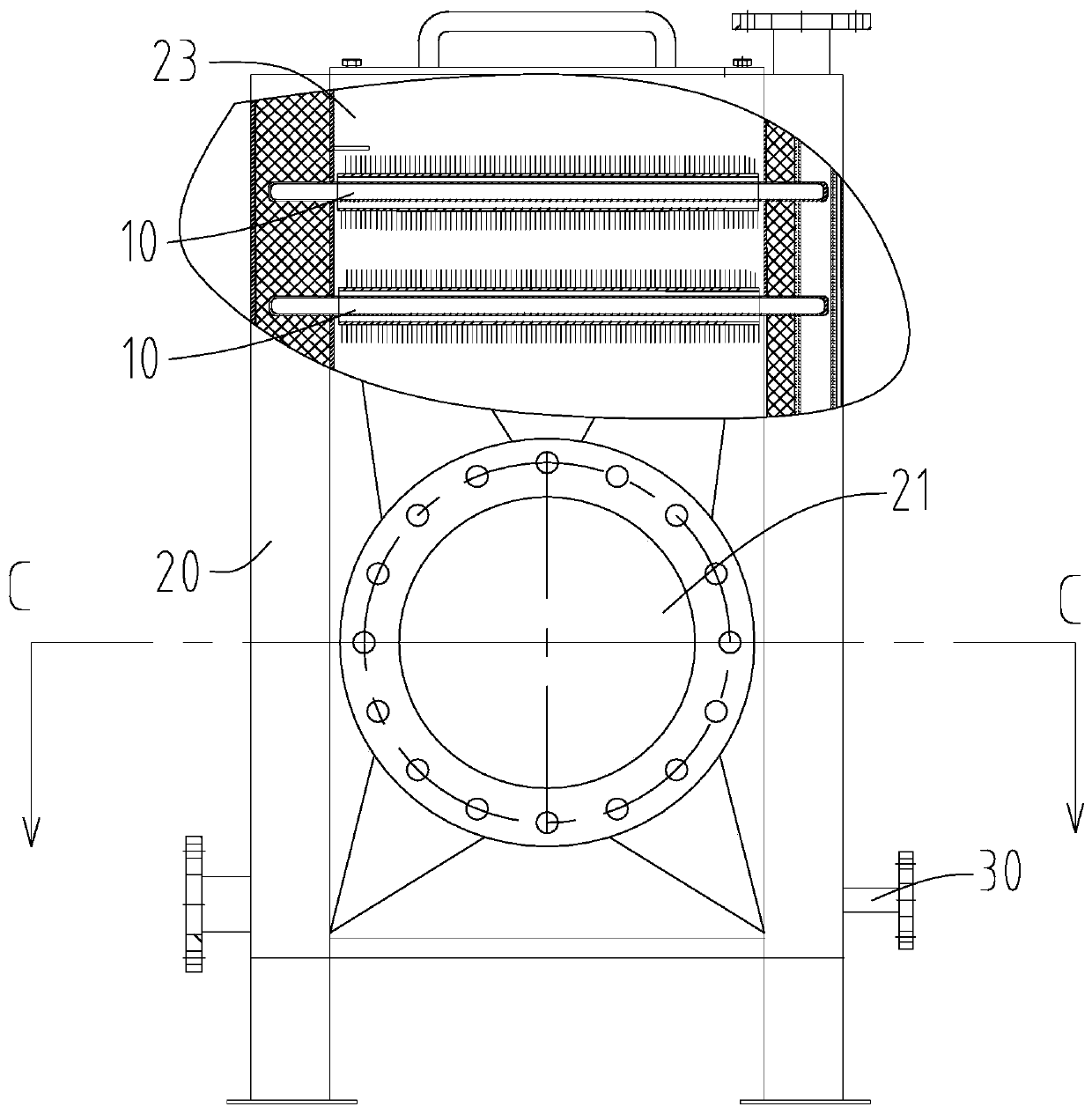

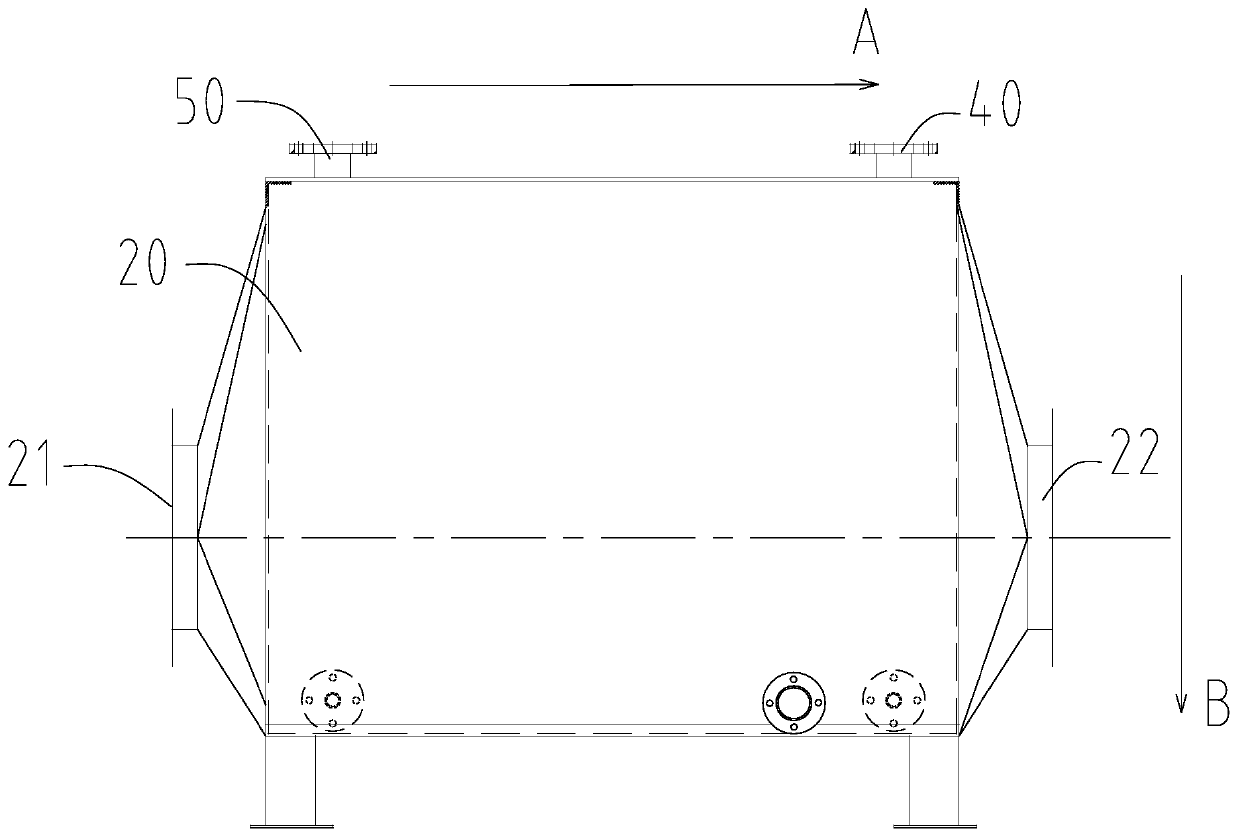

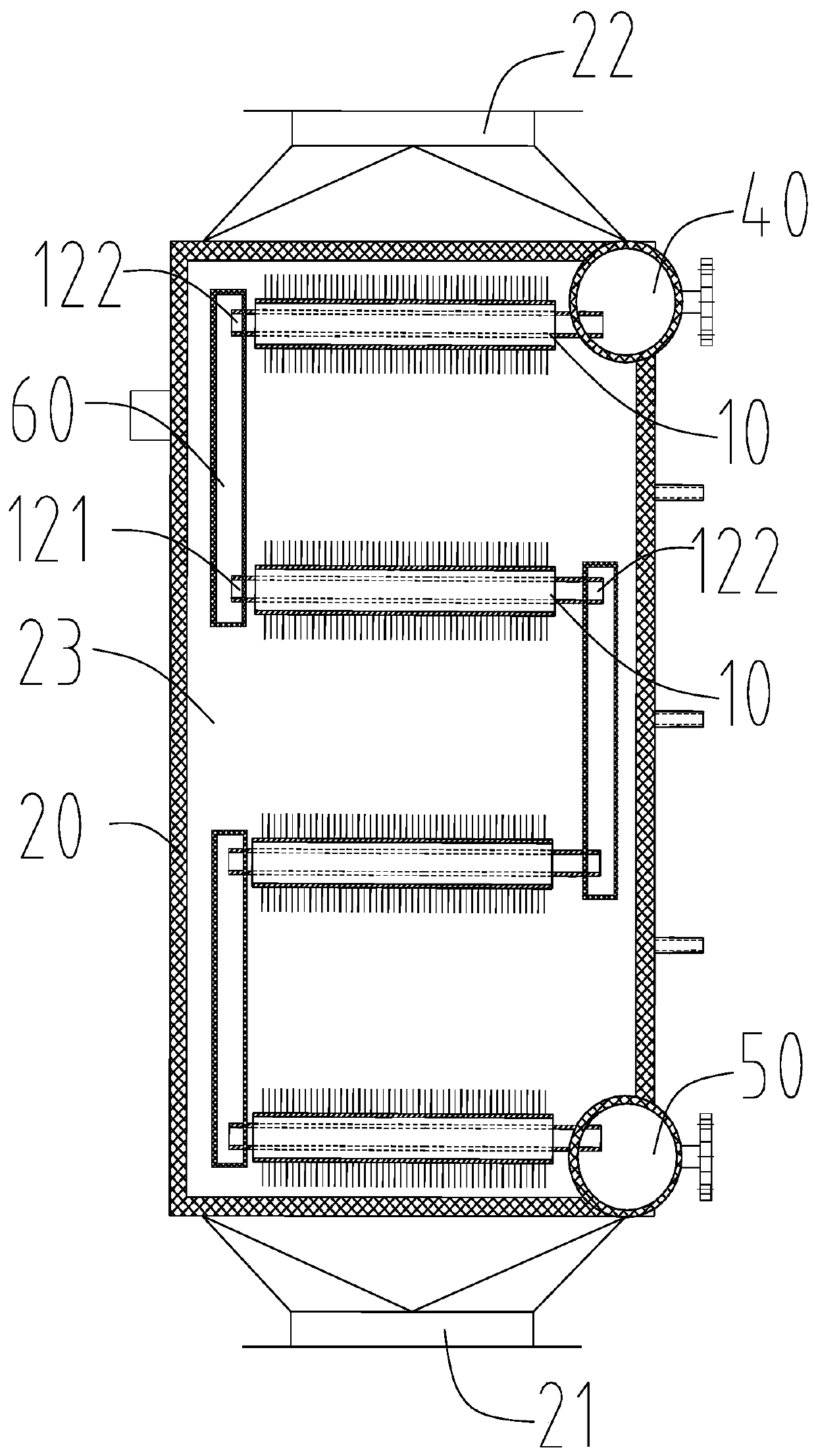

[0028] like Figure 4 The shown heat pipe 10 includes an outer tube body 11 and an inner tube body 12; the inner tube body 12 is penetrated in the outer tube body 11 and is formed with a cooling channel 123 for the passage of an external cooling liquid; the inner tube body The opposite ends of the body 12 protrude out of the outer tube body 11 respectively, and are respectively formed with a liquid inlet 121 and a liquid outlet 122; For external cooling liquid to enter and exit the cooling channel 123, the cooling liquid can be water or the like; a vacuum cavity 13 is formed between the inner tube body 12 and the outer tube body 11, and the vacuum cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com