Method for degrading polymer-containing waste water in oil field by using improved Fenton system

An improved oilfield technology, applied in water/sewage treatment, chemical instruments and methods, reduced water/sewage treatment, etc., can solve the problems of difficult to effectively degrade poly-containing sewage, expensive reagents, insufficient degradation, etc., to achieve enhanced oxidation Degradation effect, low price, effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

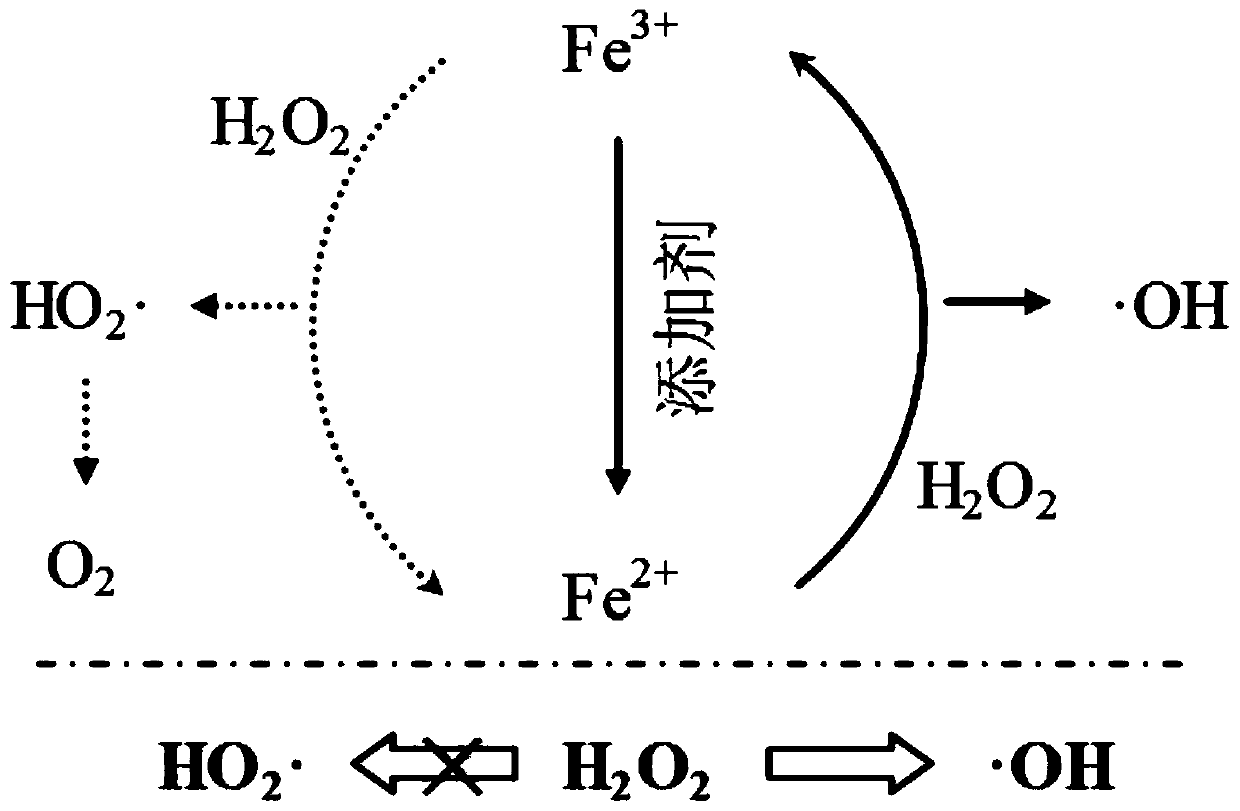

[0030] Specific implementation mode one: the present implementation mode is a kind of improved Fenton system degrading the method for oil field poly-containing sewage and is finished according to the following steps:

[0031] 1. Add H to the oilfield wastewater containing polymer 2 o 2 solution and Fe 2+ Reagent, obtain solution A;

[0032] H in solution A described in step 1 2 o 2 The concentration is 3mmol / L~11mmol / L;

[0033] Fe in solution A described in step 1 2+ The concentration is 0.5mmol / L~1.5mmol / L;

[0034] Two, add ascorbic acid in solution A, then stir reaction, obtain the sewage that removes polyacrylamide;

[0035] Ascorbic acid described in step 2 and Fe in solution A 2+ The molar ratio is (1~10):1.

[0036] The beneficial effect of this implementation mode:

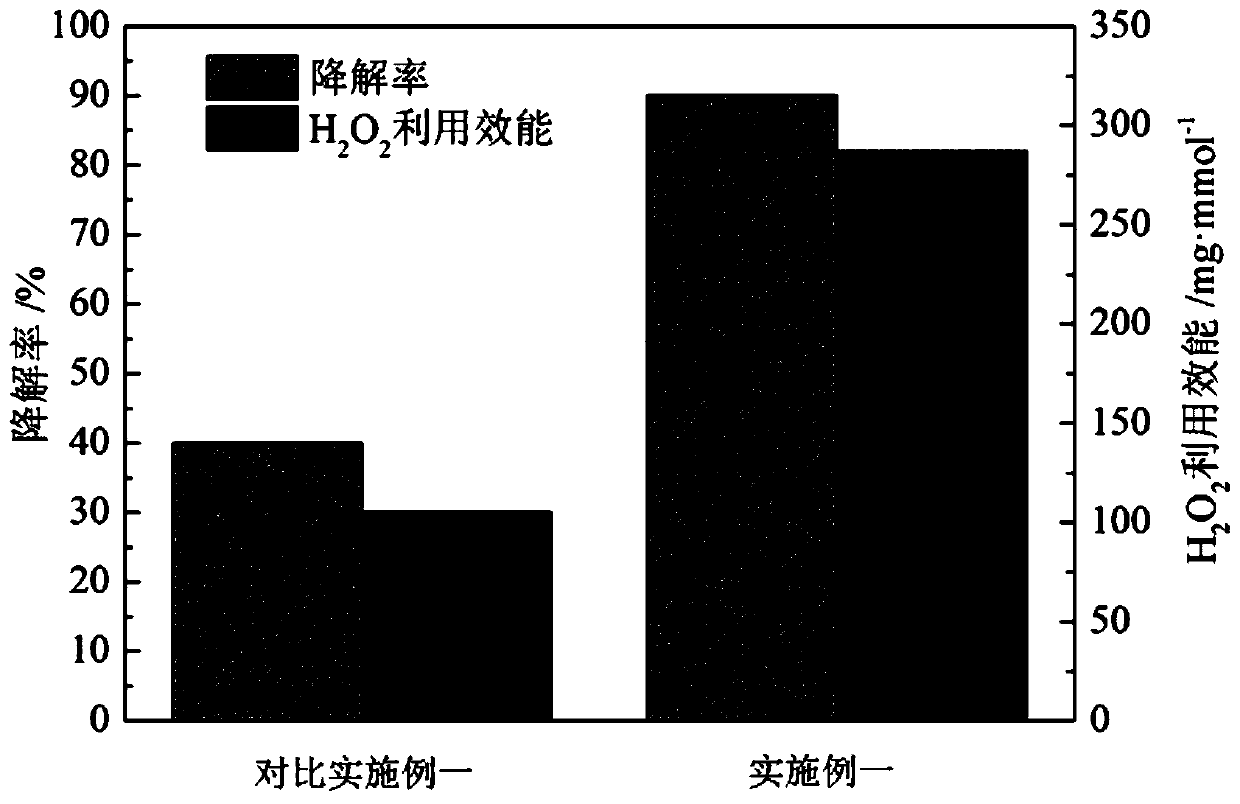

[0037] 1. The improved Fenton system used in this embodiment can efficiently degrade poly-containing sewage, which solves the problems of difficult degradation of poly-contained sewage and low d...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that: the temperature of the oil field poly-containing sewage described in step 1 is 20°C-60°C, and the stirring speed is 400r / min-600r / min. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific implementation mode three: the difference between this implementation mode and specific implementation modes one or two is: the H described in step one 2 o 2 The mass fraction of the solution is 30%. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com