Self-adaptive rewinding device

A self-adapting, driving device technology, applied in the direction of winding strip, transportation and packaging, thin material handling, etc., can solve the problems of affecting accuracy, increasing the difficulty of disassembly, and loss of parts, so as to improve the rewinding efficiency and improve the The effect of roll quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

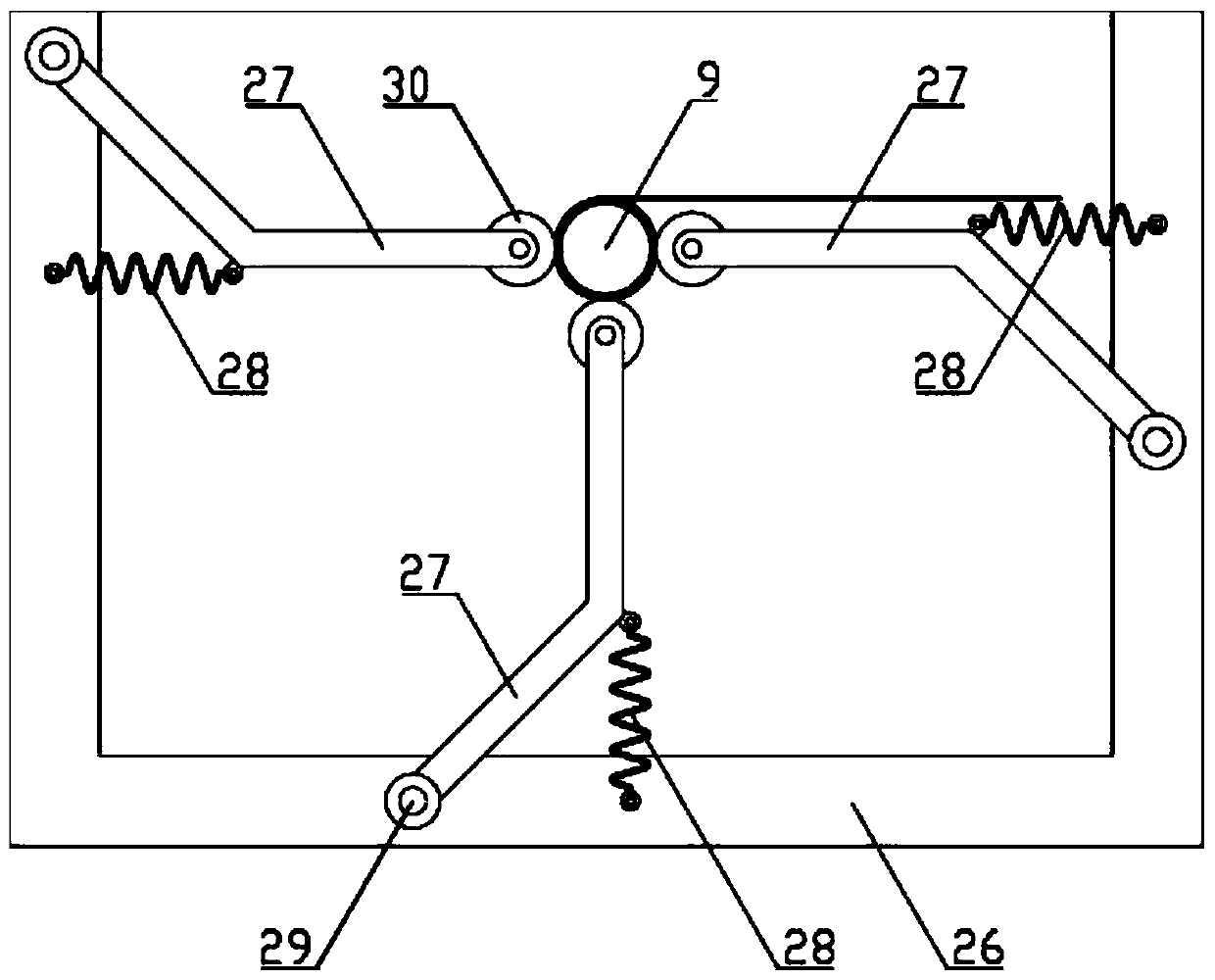

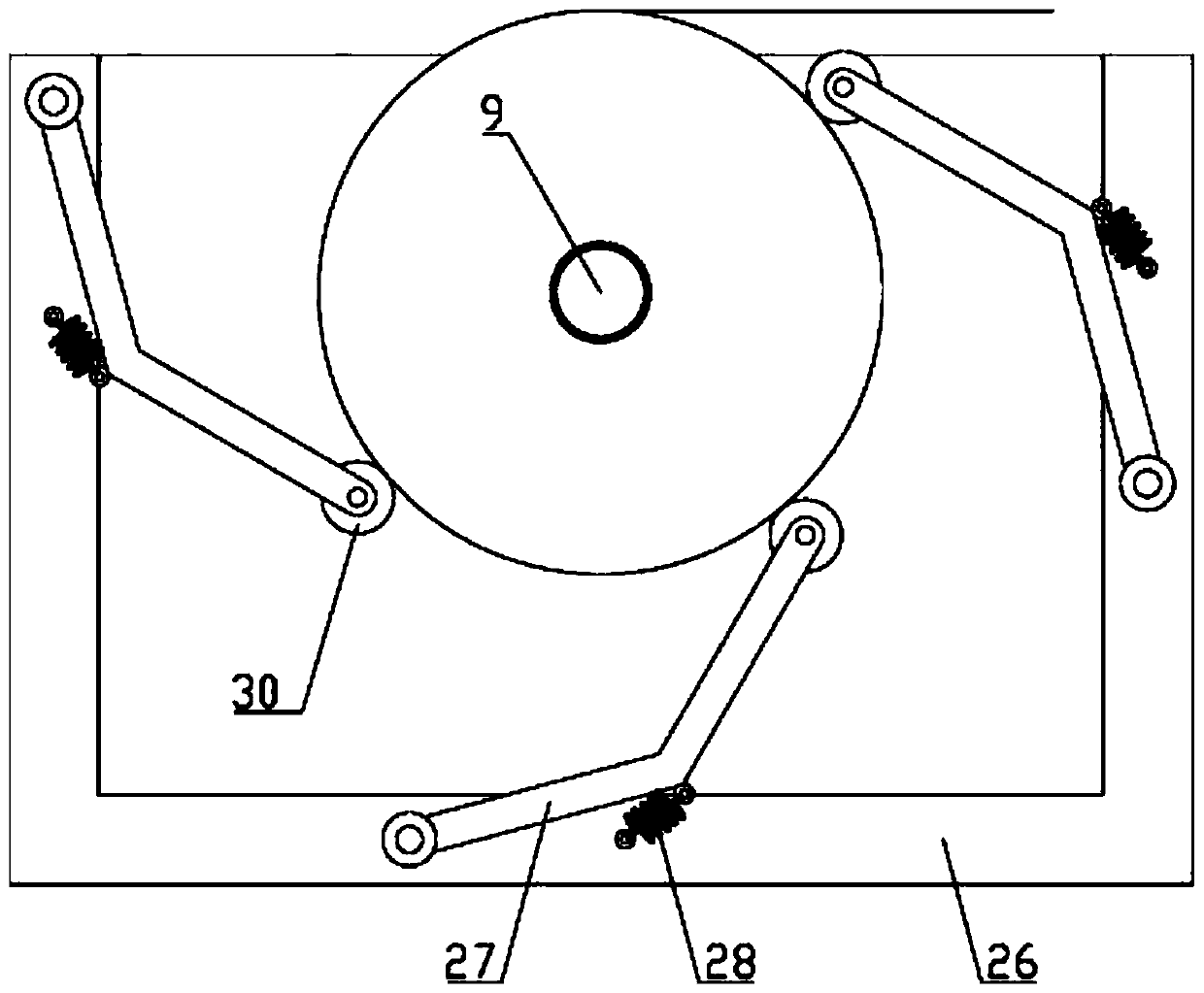

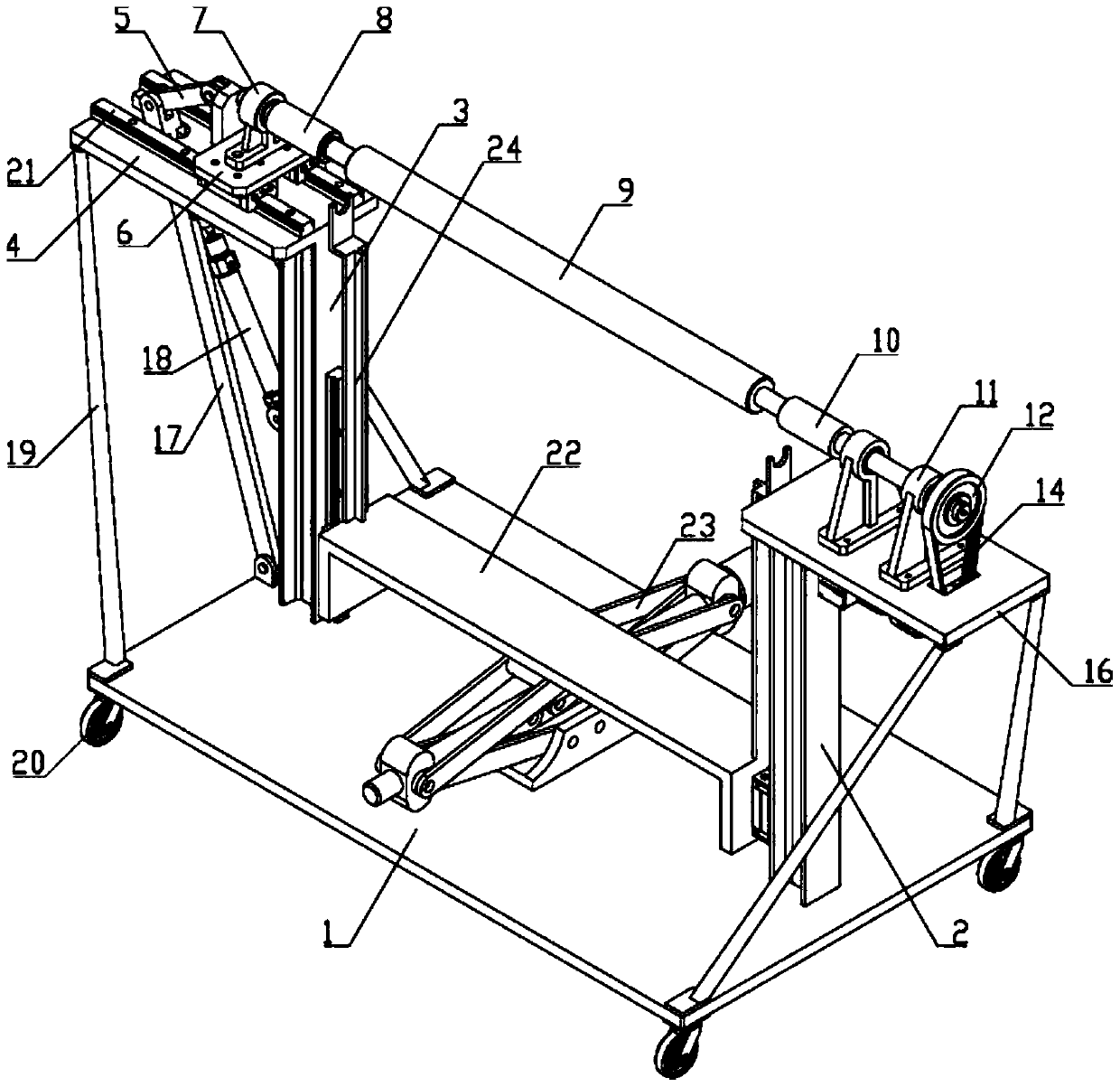

[0024] Such as Figures 1 to 4 As shown, the improvement of the present invention only lies in the improvement and optimization of the parts at the winding place, and does not involve changes to the overall structure, for example, the positional relationship and structure of other rollers other than the rewinding roller 9 are not modified. Specifically, an adaptive rewinding device includes a main frame 1, and the main frame 1 is also provided with a sub-frame 26 and a film roll 9 driven by the driving device 2 to rotate around its own axis, and the sub-frame 26 is provided with There is at least one swing arm 27 that swings within a certain range and a resetter 28 that makes the swing arm 27 have a reset tendency. The swing arm 27 is provided with a detector 29 and a pinch wheel 30 that detects its swing angle. 30 is affected by the action of the film on the rolling film roller 9 to make the swing arm 27 rotate around its axis of rotation, and make the detector 29 obtain corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com