Alternative Clamping Mechanism of Automatic Rewinder

A technology of clamping mechanism and rewinding machine, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of low efficiency and inconsistent rewinding effect, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

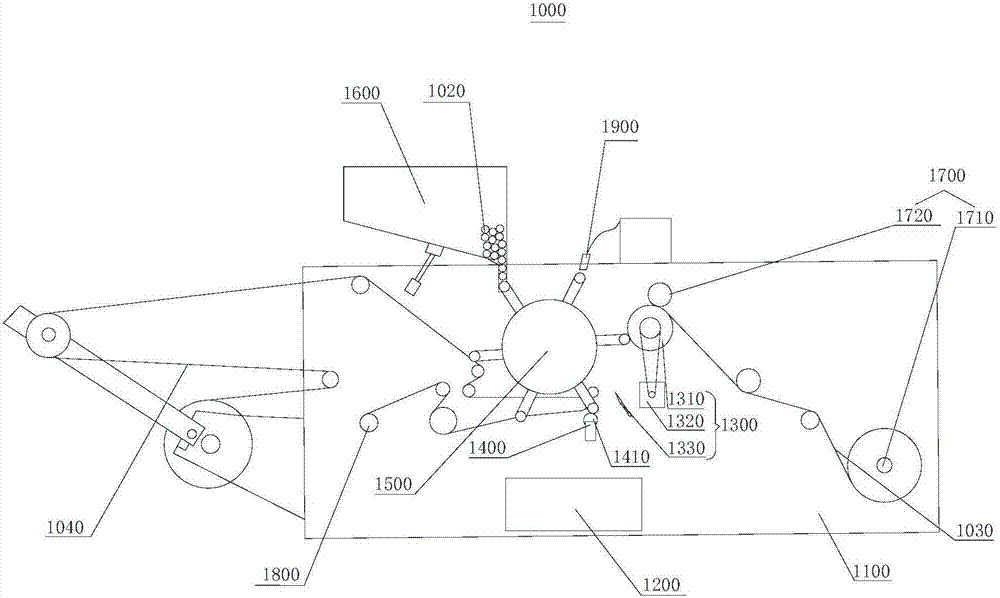

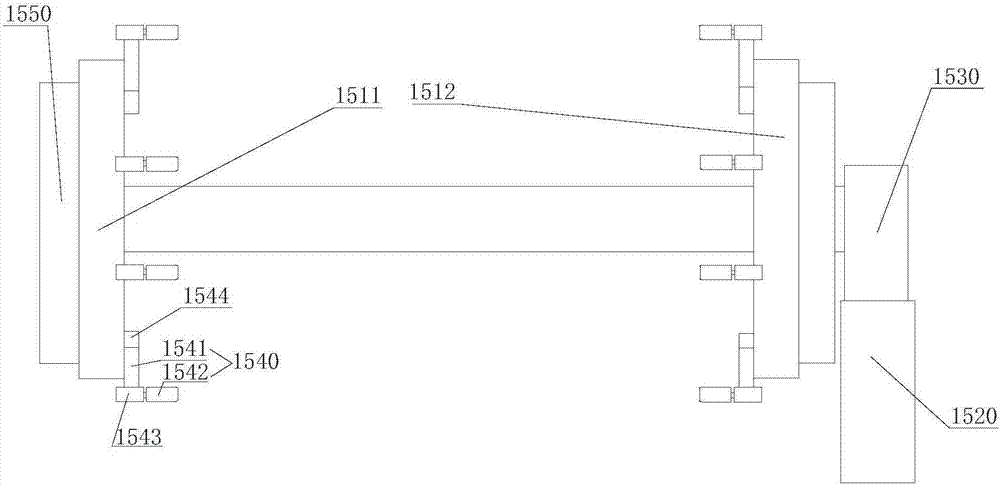

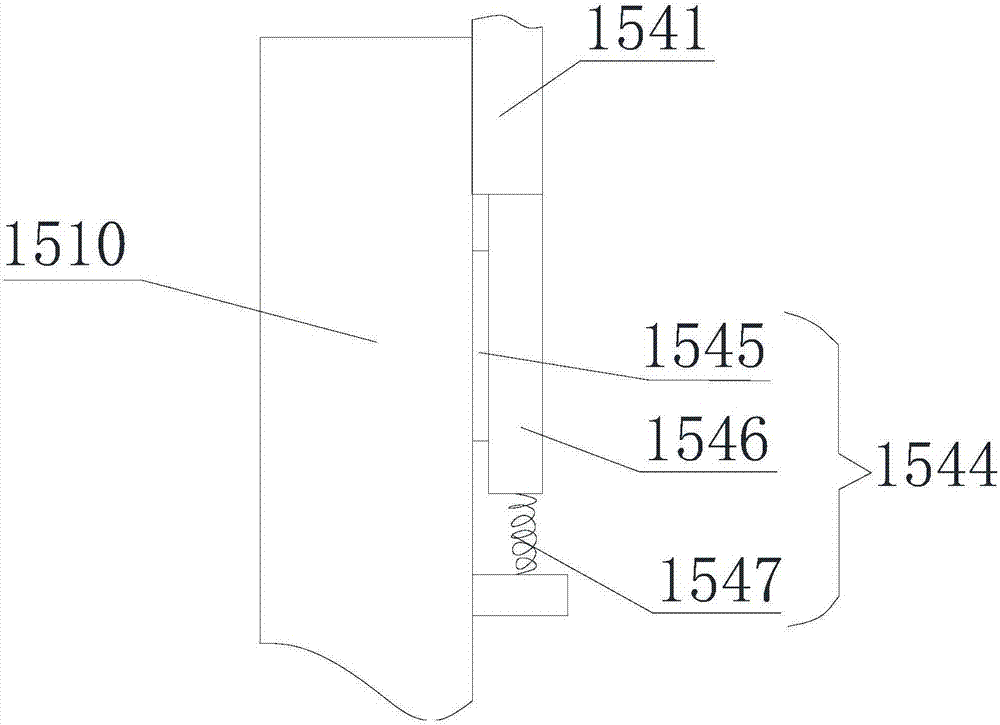

[0025] See attached figure 1 , the rotating clamping mechanism 1500 provided by the embodiment of the present invention is mainly applied to the automatic rewinding machine 1000. The qualified product after rewinding is to tightly wrap the fixed-length raw material 1030 on the paper tube 1020, and use the label to The cuts are glued so that the raw material 1030 does not come loose. And the concrete operation of forming above-mentioned product needs to be cut off after wrapping a certain length of raw material 1030 of a large roll on paper tube 1020, then carry out labeling and sealing. Further, in this embodiment, the raw material 1030 for rewinding is aluminum foil. Certainly, other materials 1030 such as films may also be used in other embodiments.

[0026] See attached figure 1 , the automatic rewinder 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com