Nickel titanium spring production equipment and application method thereof

A technology for producing equipment and equipment, which is applied in the direction of manufacturing springs, other household appliances, and metal processing equipment from wires, which can solve the problems of easily scratching the surface of nickel-titanium alloy wires, failing to meet product surface requirements, and reducing product qualification rates. Achieve the effect of reducing labor costs and risks, saving manpower, and avoiding visual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

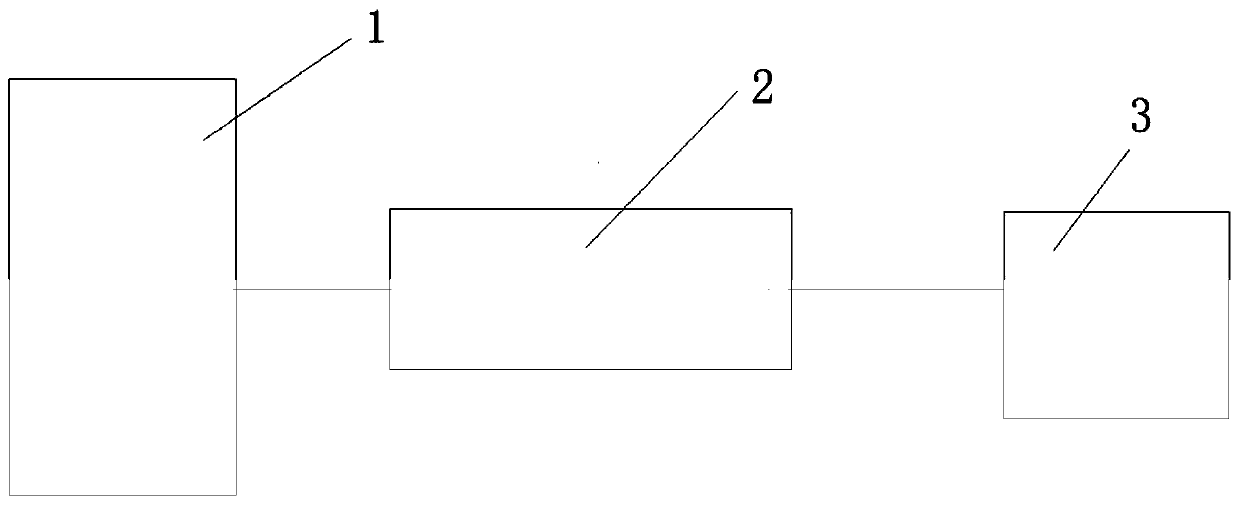

[0025] see Figure 1 to Figure 7 , the present invention relates to a nickel-titanium spring production equipment and its use method, the production equipment includes centerless grinding equipment 1, hot drawing equipment 2 and spring winding equipment 3, the centerless grinding equipment 1 is located in the hot drawing equipment 2 on the front side, the spring winding equipment 3 is arranged on the rear side of the spring winding equipment 2.

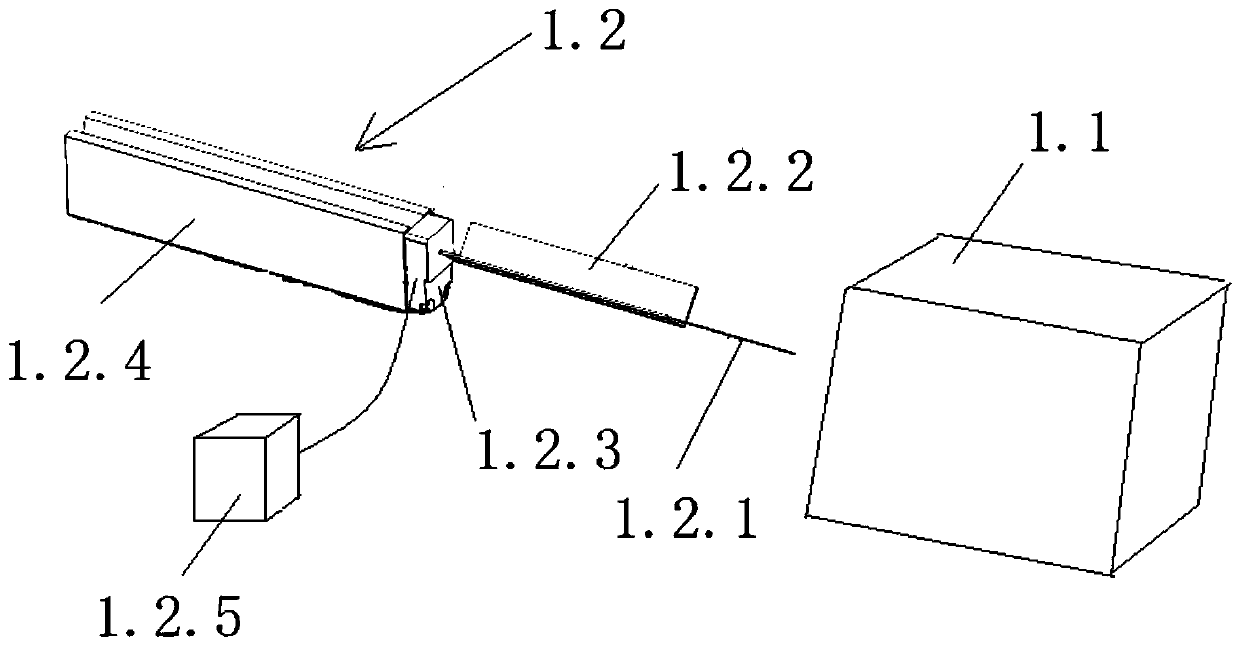

[0026] The centerless grinding equipment 1 includes a grinding machine 1.1, the grinding machine 1.1 is used for centerless grinding of nickel-titanium alloy wire, the front side of the grinding machine 1.1 is provided with a grinding length control device 1.2, and the grinding length control device 1.2 It includes a material rack 1.2.2, the material rack 1.2.2 is V-shaped, the V-shaped groove of the material rack 1.2.2 is used to carry the wire material 1.2.1 to be ground, and the material rack 1.2.2 The front end is close to the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com