Method for setting cold-rolled strip steel target plate-shaped curve as well as computer equipment

A target curve and cold-rolled strip technology, which is applied in the field of strip rolling, can solve problems such as unsatisfactory shape quality, and achieve the effects of improving subsequent shape quality, setting rationally, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

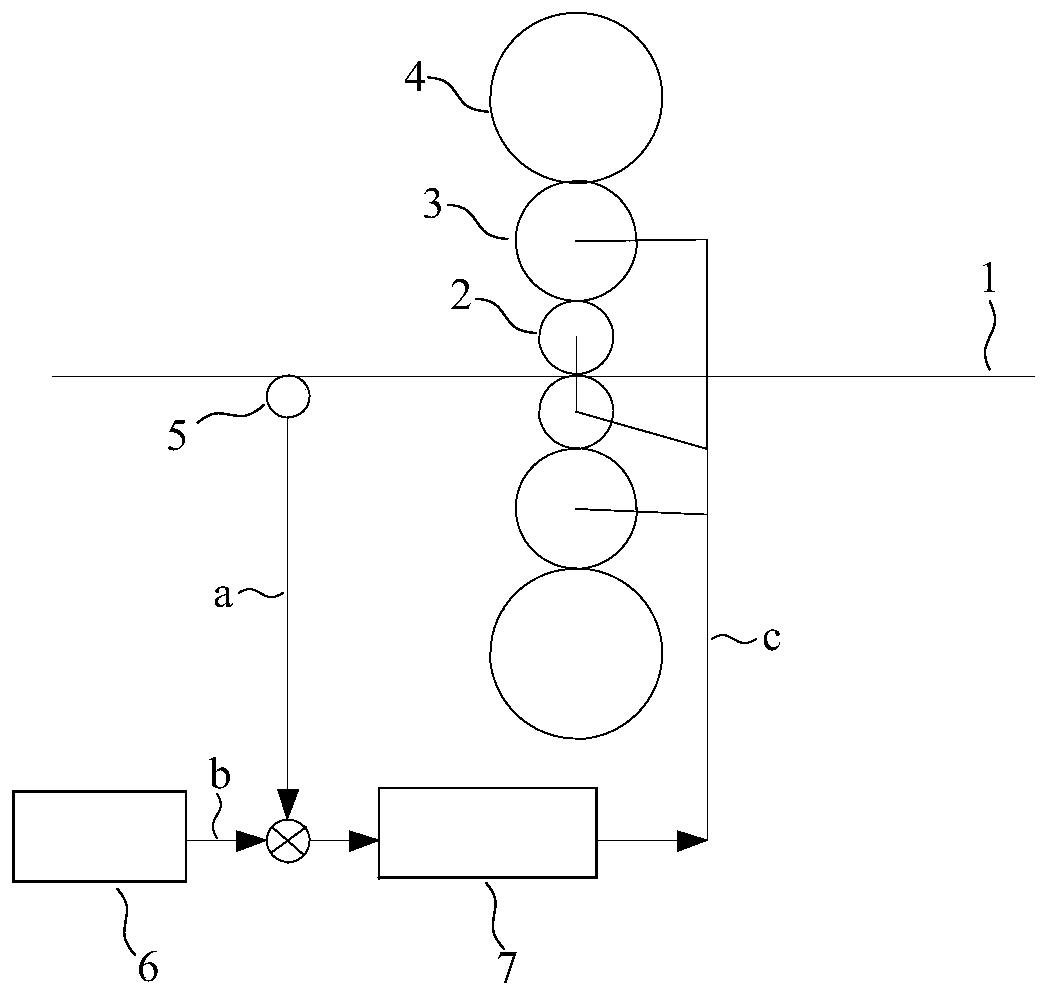

[0060] As mentioned above in the background technology, in order to obtain high-quality cold-rolled plate and strip products, modern cold-rolled production enterprises have widely adopted advanced flatness feedback control systems. Such as figure 1 Shown is a six-high cold rolling mill equipped with a flatness feedback control system, which can be a single-stand reversing six-high cold rolling mill or the last stand of a tandem cold rolling mill including a combined pickling mill. Among them, 1 is strip steel, 2, 3, and 4 are work rolls, intermediate rolls, and backup rolls, respectively, one upper and lower, and the shape roll 5 at the exit of the rolling mill measures the real-time signal a of the shape distribution and sets the target shape The target flatness curve b output by computer 6 is compared, and the obtained flatness deviation distribution is sent to flatness control computer 7. After being processed by a certain mathematical model and control algorithm, flatness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com