Hot melt adhesive injection valve

A technology of jet valve and hot melt adhesive, which is applied in the direction of coating, device for coating liquid on the surface, etc. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the present invention clearer, the various embodiments to be described below will refer to the corresponding drawings, and these drawings constitute a part of the embodiments, which describe various possible implementations of the present invention. kind of embodiment. It is to be understood that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

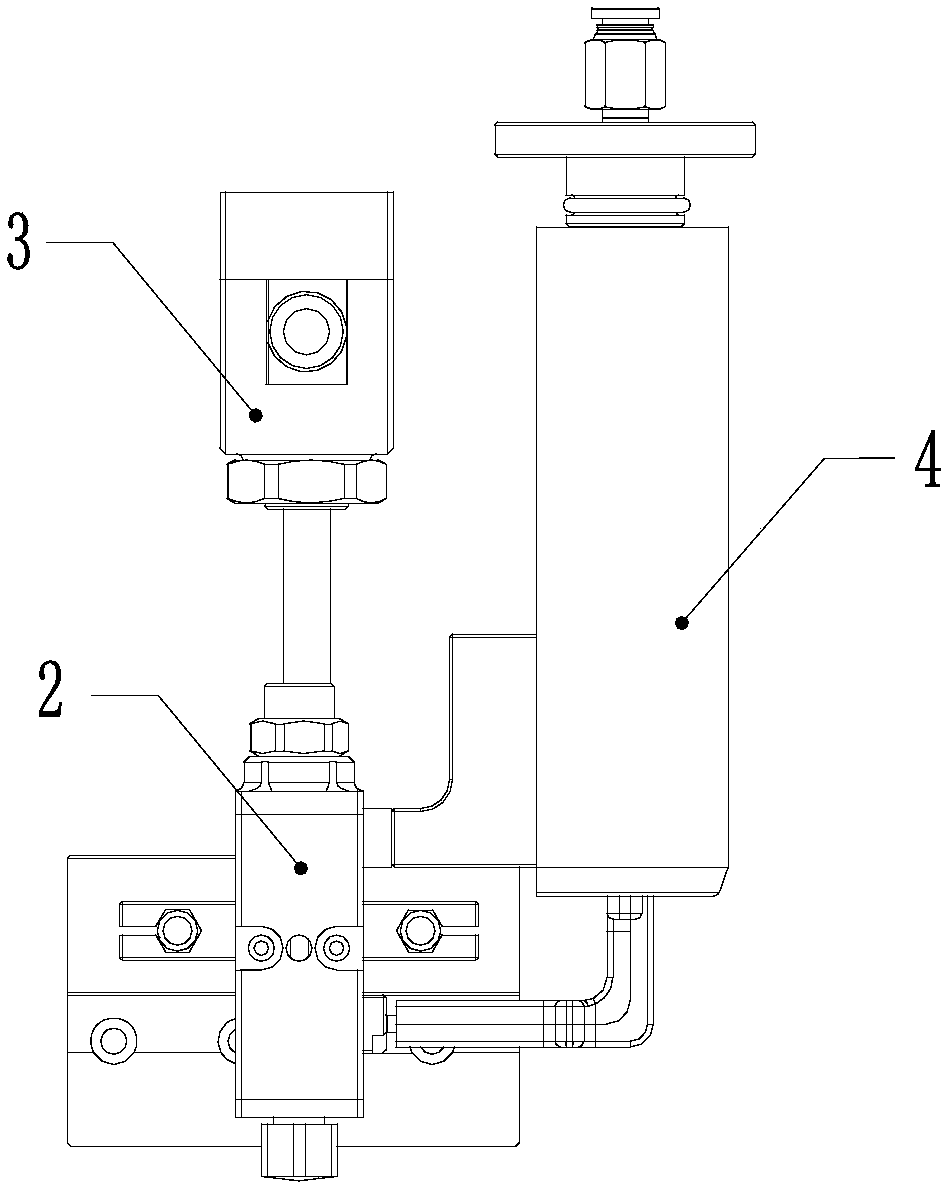

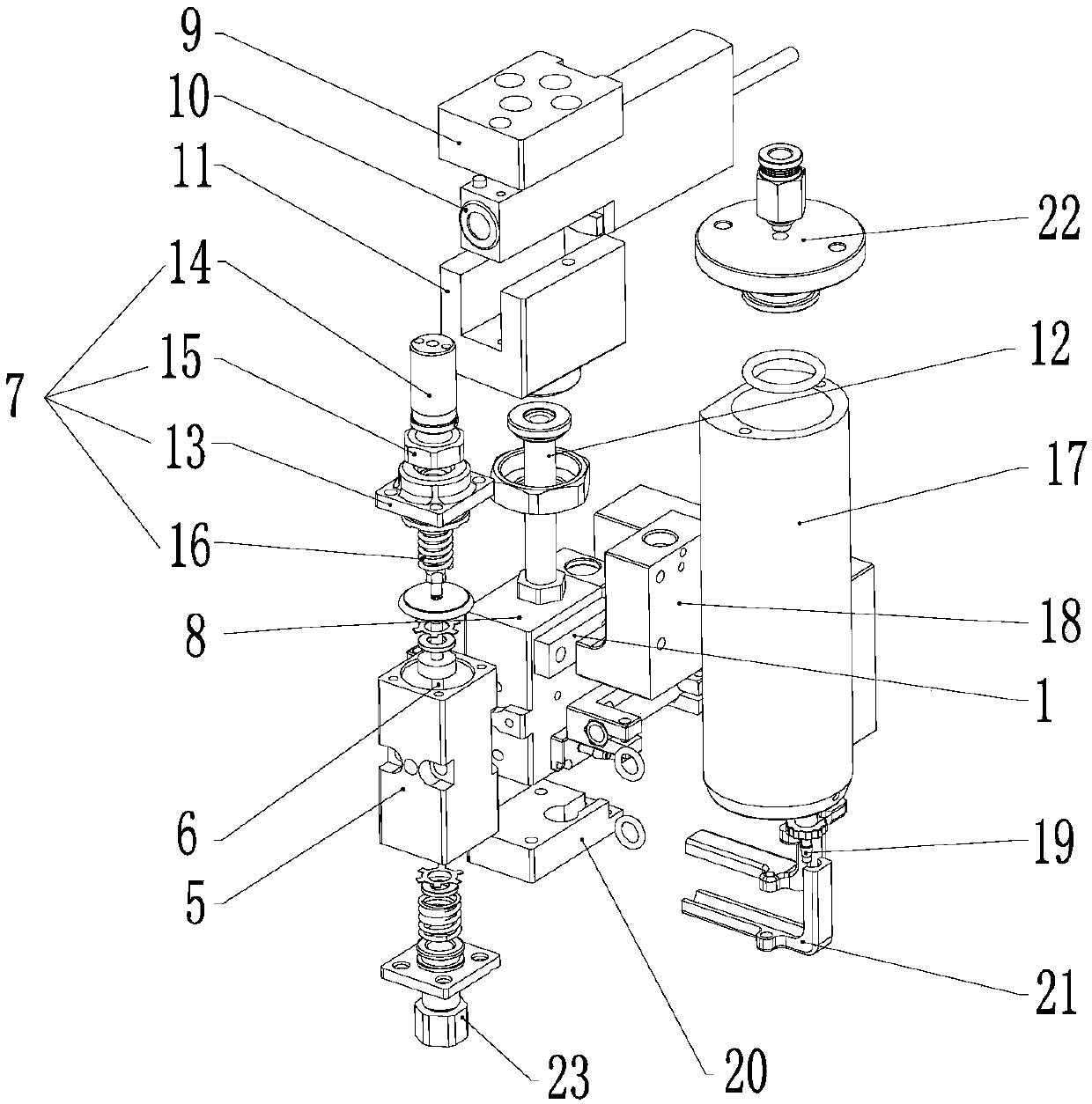

[0027] Such as Figure 1-Figure 4 Shown, the hot melt glue injection valve of the present embodiment:

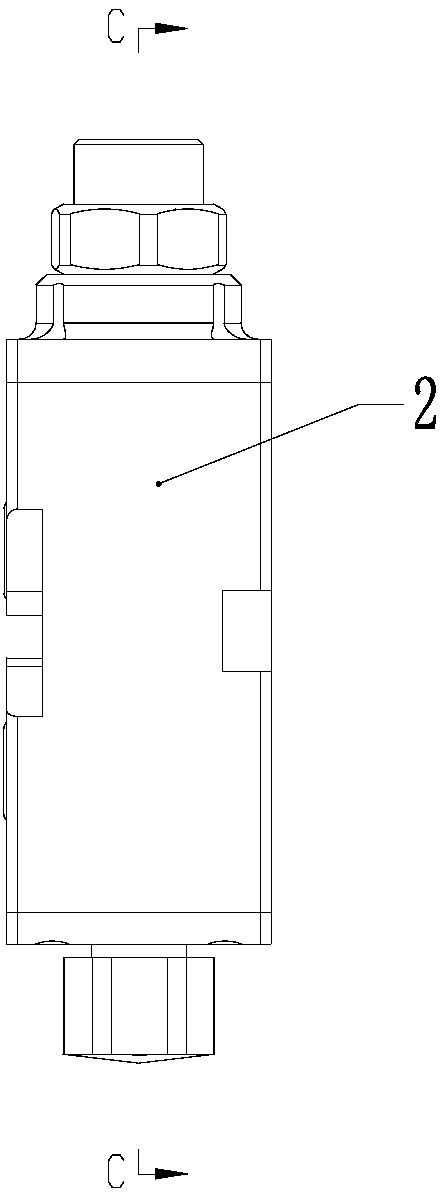

[0028] It includes a heat insulating element 1, a valve body assembly 2, and a solenoid valve assembly 3 and a heating barrel assembly 4 respectively connected to the valve body assembly 2;

[0029] The valve body assembly 2 includes a main body 5, a striker mechanism 6 pierced in the main body 5, and an adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com