Feed preparation raw material efficient crushing device for promoting growth of cattle

A high-efficiency crushing and feed technology, which is applied in feed, grain processing, food science, etc., can solve the problems of inability to grind feed, reduce the efficiency of crushing, and reduce the service life of equipment, so as to increase the granularity of feed, improve the quality of crushing, and ensure The effect of crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

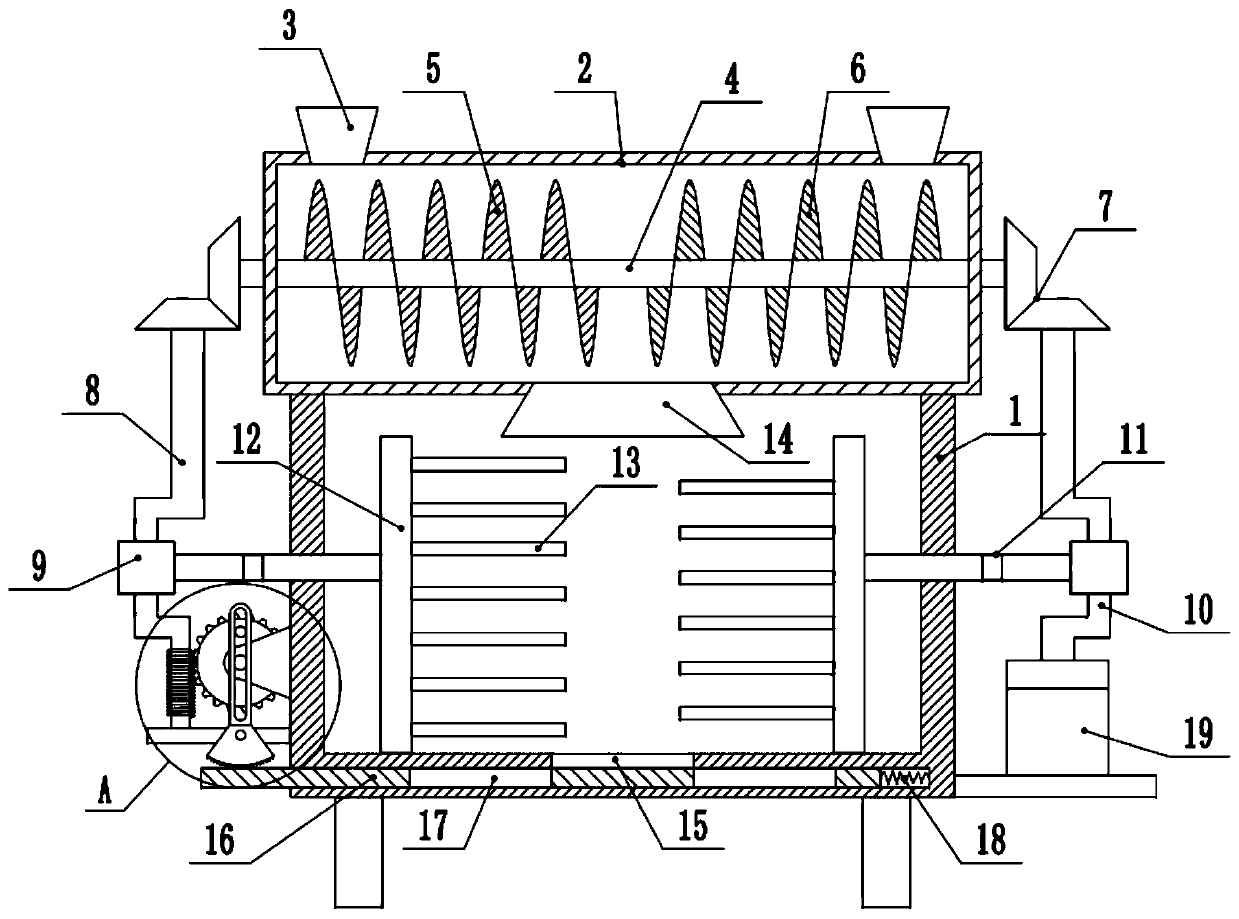

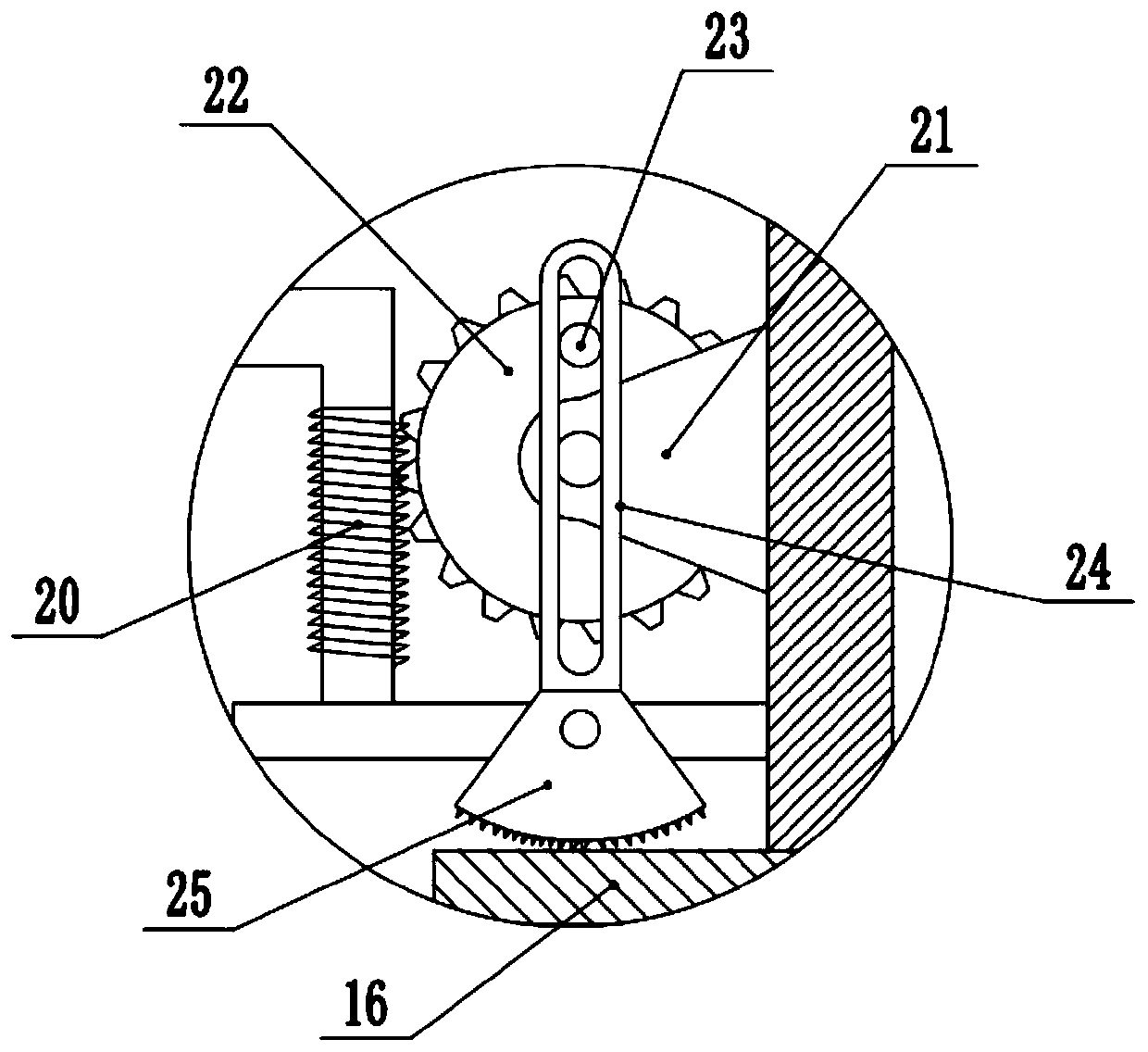

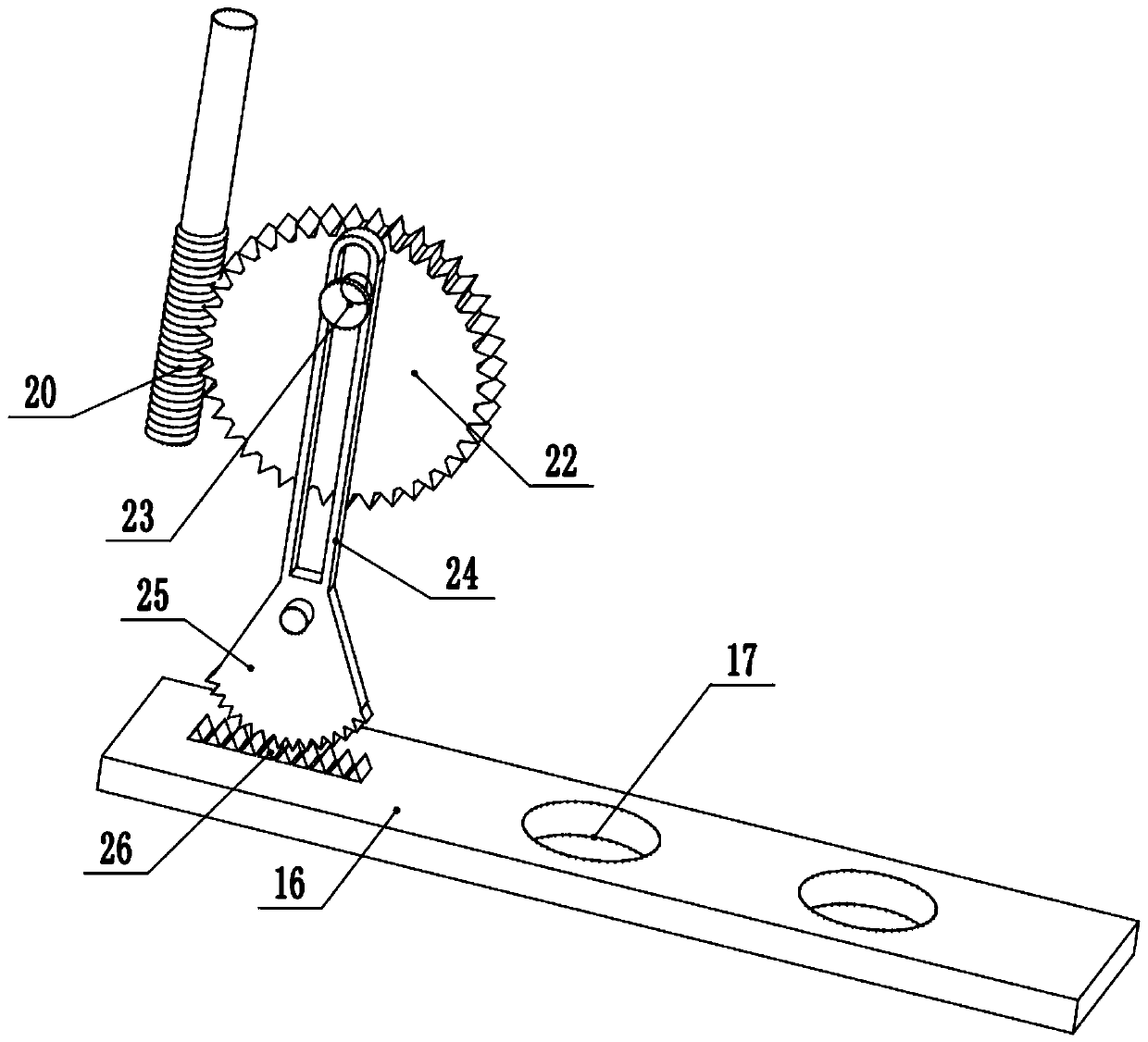

[0026] refer to Figure 1~3 , in an embodiment of the present invention, a high-efficiency crushing device for raw materials for feed production that promotes cattle growth includes a crushing box 1 and a crushing cylinder 2 arranged at the upper end of the crushing box 1, and a feeding hopper 3 is installed on both sides of the upper end of the crushing cylinder 2, It is used for the staff to put the raw materials to be crushed into the crushing cylinder 2. A hopper 14 is installed in the middle of the lower end of the crushing cylinder 2. It is used to introduce the feed raw materials into the crushing box 1 after preliminary crushing. The two sides of the lower end of the crushing box 1 are Supporting legs are installed to support and fix the entire device. A motor plate is installed at the lower end of the right end of the crushing box 1, and a rotating motor 19 is installed on the upper end of the motor plate to provide a power source for the normal operation of the entire...

Embodiment 2

[0028] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a guide spring 18 is installed between the right end of the moving plate 16 and the guide groove, and by setting the guide spring 18, the movement of the moving plate can be guaranteed. 16 will not produce a wide range of shaking during the left and right movement, ensuring that the discharge hole 17 and the discharge hopper 15 can be stably aligned.

[0029]In the present invention, when working, the raw materials to be pulverized are placed in the feeding hopper 3, and the rotating motor 19 is started at the same time, and the rotating motor 19 drives the transmission shaft 8 on the right side to rotate, and then through the action of the gear set 7, the rotating shaft 4 drives the two The crushing screw on the side rotates to crush the raw materials while moving to the middle of the crushing cylinder 2, and then enters the inside of the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com