Preparation method of nickel phosphide/TpPa-2 composite material and hydrogen production method by photolyzing water

A composite material, tppa-2 technology, applied in organic compound/hydride/coordination complex catalysts, hydrogen/syngas production, chemical/physical processes, etc., can solve the problem of low efficiency of photo-splitting water for hydrogen production, etc. To achieve the effect of improving the performance of photo-splitting water for hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

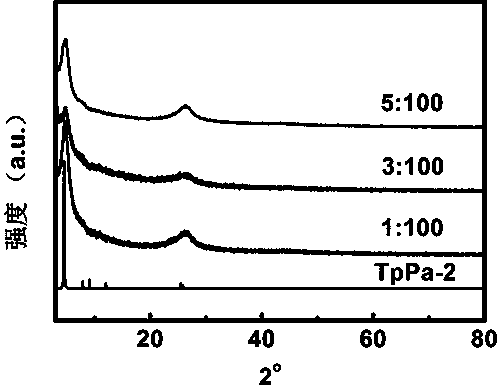

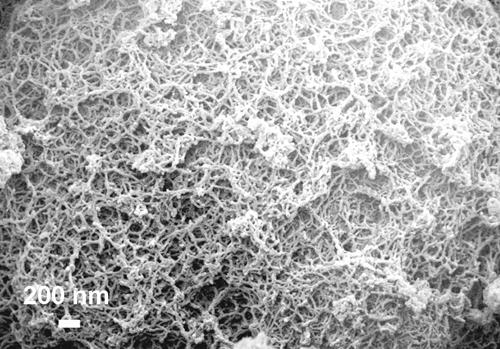

[0018] Specific embodiment one: a kind of Ni of this embodiment 2 The preparation of P / TpPa-2 material is finished according to the following steps:

[0019] Step 1, preparation of TpPa-2;

[0020] Step two, Ni 2 Preparation of P / TpPa-2: TpPa-2 (60mg) and NiCl 2 ·6H 2 O (1.98mg), NaH 2 PO 2 ·H 2 O (9.9mg) was placed in a mortar evenly, then transferred to a magnetic state, heated to 200°C in a tube furnace under a nitrogen atmosphere (the heating rate was 5°C / min) and kept for 1h, and washed several times by centrifugation with water and ethanol , dried in an oven at 80°C for 10 h to obtain Ni 2 P / TpPa-2 (mass ratio 1:100) composite material;

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the NiCl described in step two 2 ·6H 2 The mass of O is 6 mg, NaH 2 PO 2 ·H 2 The mass of O is 30 mg, and other steps and parameters are the same as those in Embodiment 1. get Ni 2 P / TpPa-2 (mass ratio 3:100) composite material;

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the NiCl described in step three 2 ·6H 2 The mass of O is 10 mg, NaH 2 PO 2 ·H 2 The mass of O is 50 mg, and other steps and parameters are the same as those in Embodiment 1 or 2. get Ni 2 P / TpPa-2 (mass ratio 5:100) composite material;

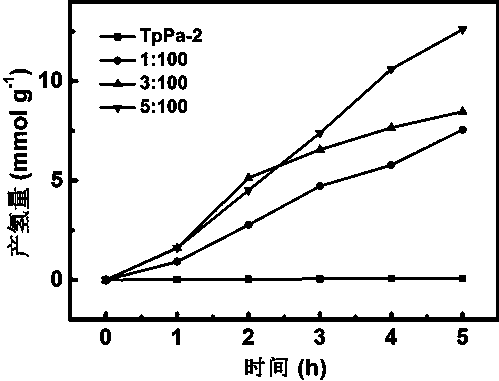

[0023] Carry out following test for verifying beneficial effect of the present invention:

[0024] To examine Ni 2 P / TpPa-2 material catalytic decomposition of water hydrogen production effect, according to the following method to test its visible light photocatalytic hydrogen production performance. The test process is as follows: The photocatalytic hydrogen production experiment was carried out in the photocatalytic activity evaluation online analysis system. Before the reaction started, the cooling circulation system was turned on to ensure that the photocatalytic reaction temperature remained at a constant temperature (4°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com