Microparticle manufacturing device and microparticle manufacturing method

A technology for manufacturing devices and particles, applied in chemical instruments and methods, transportation and packaging, and control/regulating processes, etc., can solve problems such as low processing efficiency, and achieve higher evaporation efficiency, reduction of untreated materials, and increased production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

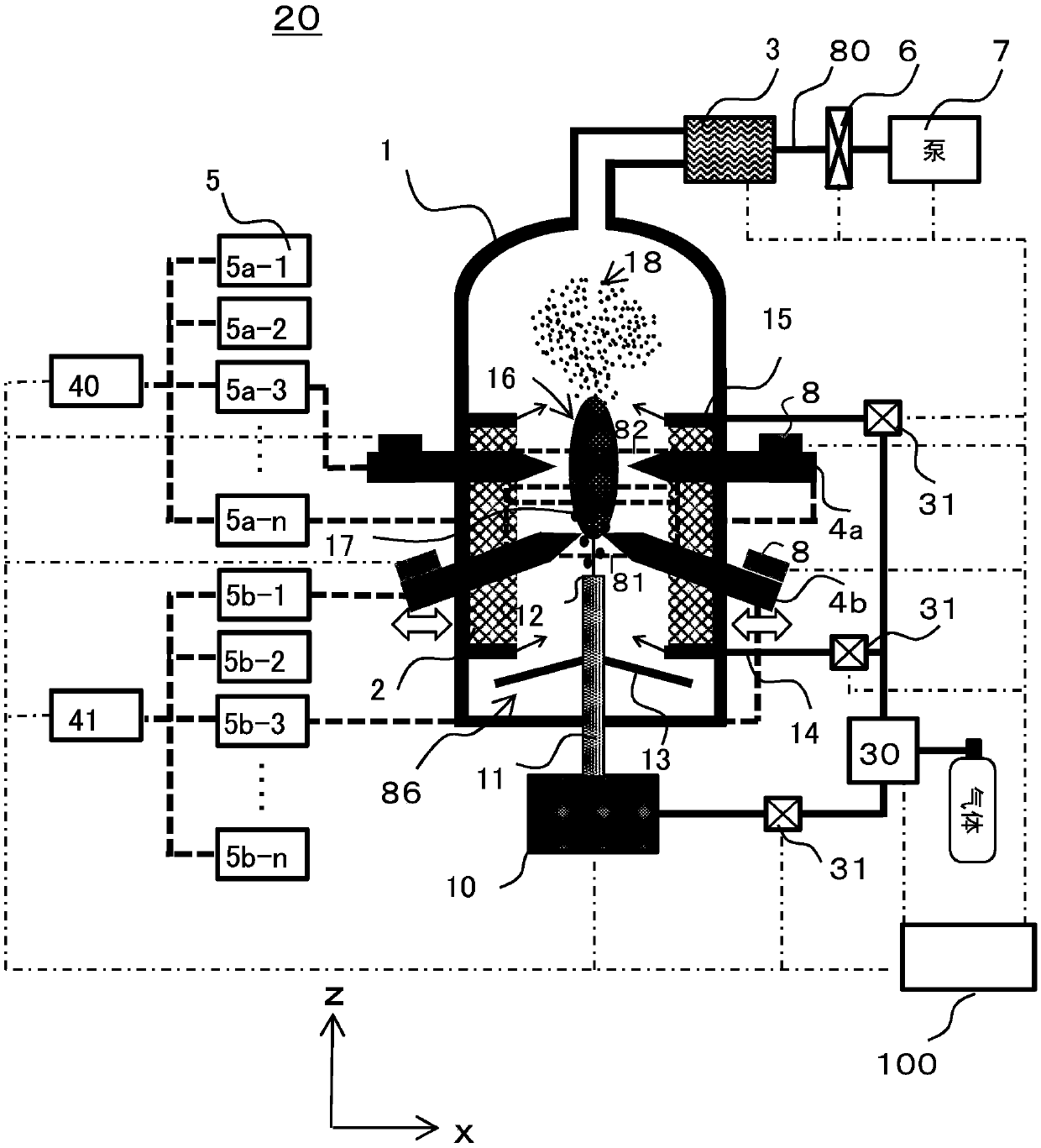

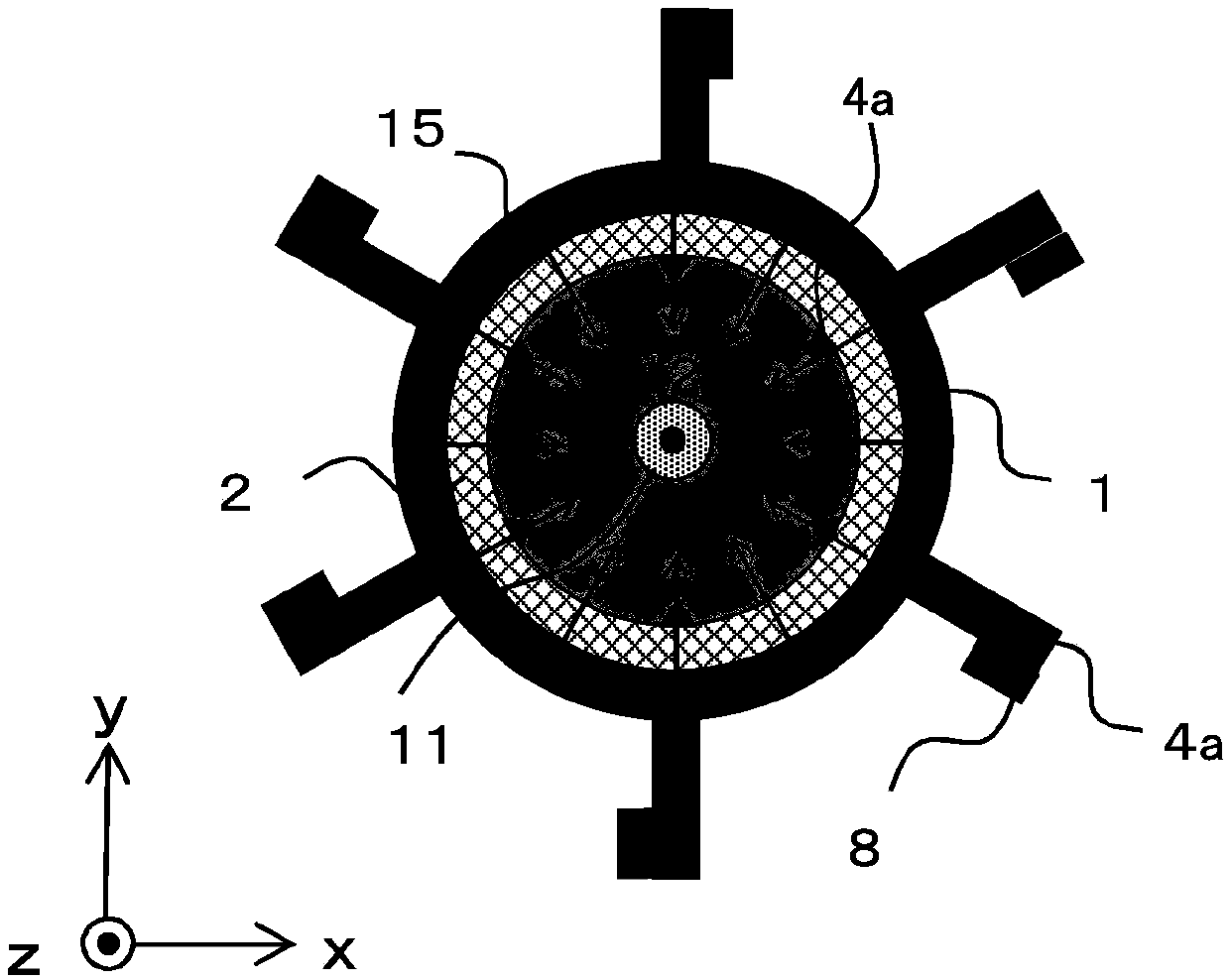

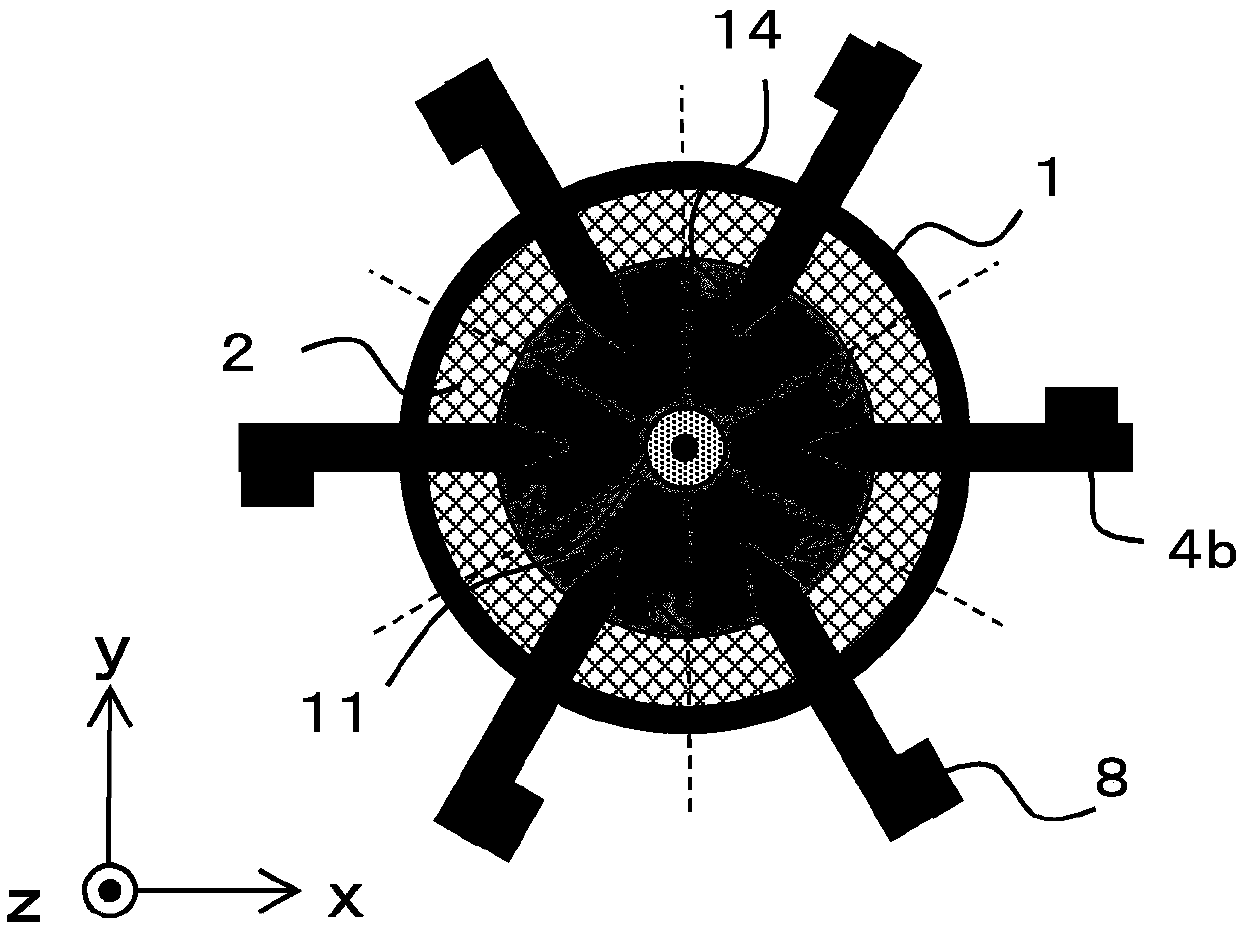

[0064] figure 1 A schematic cross-sectional view of the microparticle manufacturing apparatus 20 according to the first embodiment viewed from a direction perpendicular to the vertical direction is shown. Figure 2A It is a schematic partial cross-sectional view (x-y plan view) seen from the +z direction in the second electrode arrangement region in the vicinity of the upper electrode in the microparticle manufacturing apparatus according to the first embodiment. Figure 2B It is a schematic partial cross-sectional view (x-y plan view) seen from the +z direction in the first electrode arrangement region in the vicinity of the lower electrode. In addition, for the sake of convenience, let one direction in the horizontal plane be the x direction, and let the vertical upper direction be the z direction. use figure 1 , Figure 2A as well as Figure 2B , as an example, an example of producing nanoscale particles of silicon will be described.

[0065] The microparticle produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com