A method for evaluating grouting effect of polymer grouting material and grouting material

A technology of grouting material and grouting effect, which is applied in the field of coal mines, can solve problems such as inability to make full use of bolts (mechanical properties of cables, failure of effective support for broken surrounding rock, failure to guarantee support requirements of grouting parameters, etc., and achieve Efficient bearing capacity of the surrounding rock itself, enhancing the bearing capacity of the surrounding rock itself, and shortening the grouting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

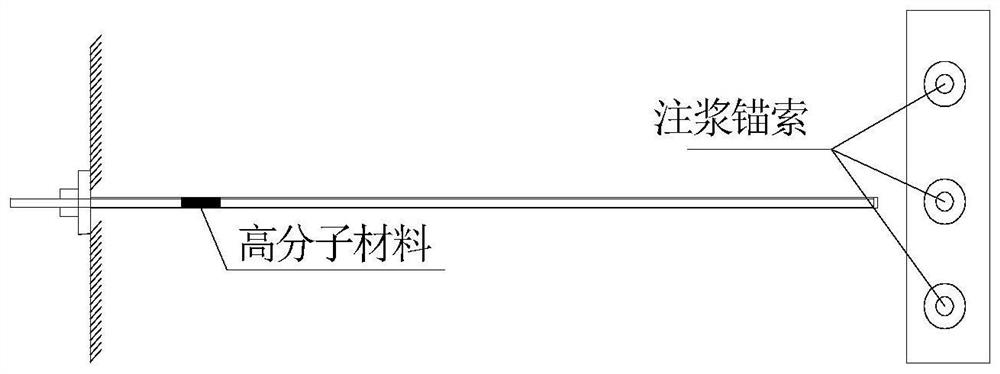

Image

Examples

Embodiment 1

[0059] A kind of polymer grouting material proposed by the present invention, the polymer grouting material includes A and B two components;

[0060] Component A is composed of the following raw materials in parts by weight: 120 parts of isocyanate, 20 parts of foaming agent, 10 parts of foam stabilizer, 8 parts of antistatic agent, 10 parts of epoxy resin, and 8 parts of epoxy resin prepolymer diluent;

[0061] Component B is composed of the following raw materials in parts by weight: 40 parts of phosphoric acid with a concentration of 85%, 30 parts of citric acid with a concentration of 65%, 20 parts of polyols, 10 parts of water-soluble trihydroxy polyether, 6 parts of curing agent, 7 parts of fuel, 5 parts of plasticizer.

[0062] The volume ratio of component A: component B is 1.5:1.

[0063] The present invention also proposes the use method of the polymer grouting material as follows: each component of the A component and the B component becomes two kinds of homogeneou...

Embodiment 2

[0065] A kind of polymer grouting material proposed by the present invention, the polymer grouting material includes A and B two components;

[0066] Component A consists of the following raw materials in parts by weight: 125 parts of isocyanate, 25 parts of blowing agent, 15 parts of foam stabilizer, 8.5 parts of antistatic agent, 15 parts of epoxy resin, and 8.5 parts of epoxy resin prepolymer diluent;

[0067] Component B is composed of the following raw materials in parts by weight: 45 parts of phosphoric acid with a concentration of 85%, 35 parts of citric acid with a concentration of 65%, 25 parts of polyols, 15 parts of water-soluble trihydroxy polyether, 6.5 parts of curing agent, Fuel agent 7.5 parts, plasticizer 5.5 parts.

[0068] The volume ratio of component A: component B is 1.5:1.

[0069] Using method is the same as embodiment one.

Embodiment 3

[0071] A kind of polymer grouting material proposed by the present invention, the polymer grouting material includes A and B two components;

[0072] Component A consists of the following raw materials in parts by weight: 130 parts of isocyanate, 30 parts of foaming agent, 20 parts of foam stabilizer, 9 parts of antistatic agent, 20 parts of epoxy resin, and 9 parts of epoxy resin prepolymer diluent;

[0073] Component B is composed of the following raw materials in parts by weight: 50 parts of phosphoric acid with a concentration of 85%, 40 parts of citric acid with a concentration of 65%, 30 parts of polyols, 20 parts of water-soluble trihydroxypolyether, 7 parts of curing agent, 8 parts of fuel, 6 parts of plasticizer.

[0074] The volume ratio of component A: component B is 1.5:1.

[0075] Using method is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com