Ozone oxidation viscosity reduction treatment device for ternary water produced from oil fields and use method of device

An ozone oxidation and treatment device technology, applied in mining wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of low oxidation efficiency, easy blockage, and hidden safety hazards in the storage of additional oxidizing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

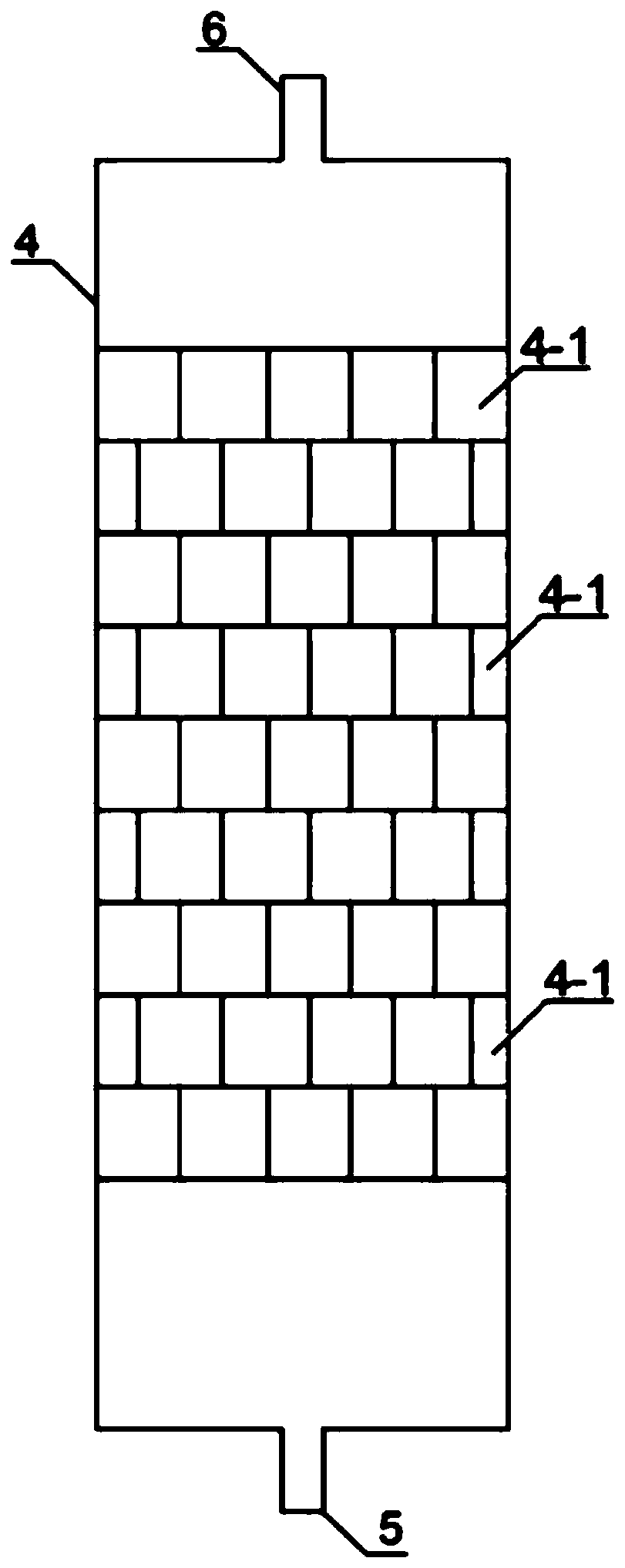

[0048] Specific implementation mode 1: This implementation mode is a treatment device for ozone oxidation and viscosity reduction of oilfield ternary production water, such as Figure 1-Figure 5 As shown, it is specifically composed of a circulating water pump 1, a Venturi tube gas / liquid mixer 2, a first-stage columnar catalytic oxidation reactor 4, a second-stage columnar catalytic oxidation reactor 7, a third-stage columnar catalytic oxidation reactor 10, Rear reaction tank 13 and ozone generator 36 are formed;

[0049] The liquid outlet of the circulating water pump 1 is communicated with the liquid inlet of the Venturi tube gas / liquid mixer 2, the gas outlet of the ozone generator 36 is communicated with the inlet 3 of the Venturi tube gas / liquid mixer 2, and the Venturi tube The liquid outlet of the gas / liquid mixer 2 communicates with the liquid inlet 5 of the first-stage columnar catalytic oxidation reactor 4, and the liquid outlet 6 of the first-stage columnar catalyt...

specific Embodiment approach 2

[0057] Embodiment 2: This embodiment is different from Embodiment 1 in that: the distance between two parallel and adjacent slices 4-1-1 is 0.5 cm to 2 cm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0058] Specific Embodiment 3: This embodiment differs from Specific Embodiment 1 or 2 in that: the angle between two intersecting and adjacent flakes 4-1-1 is 30°-90°. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com