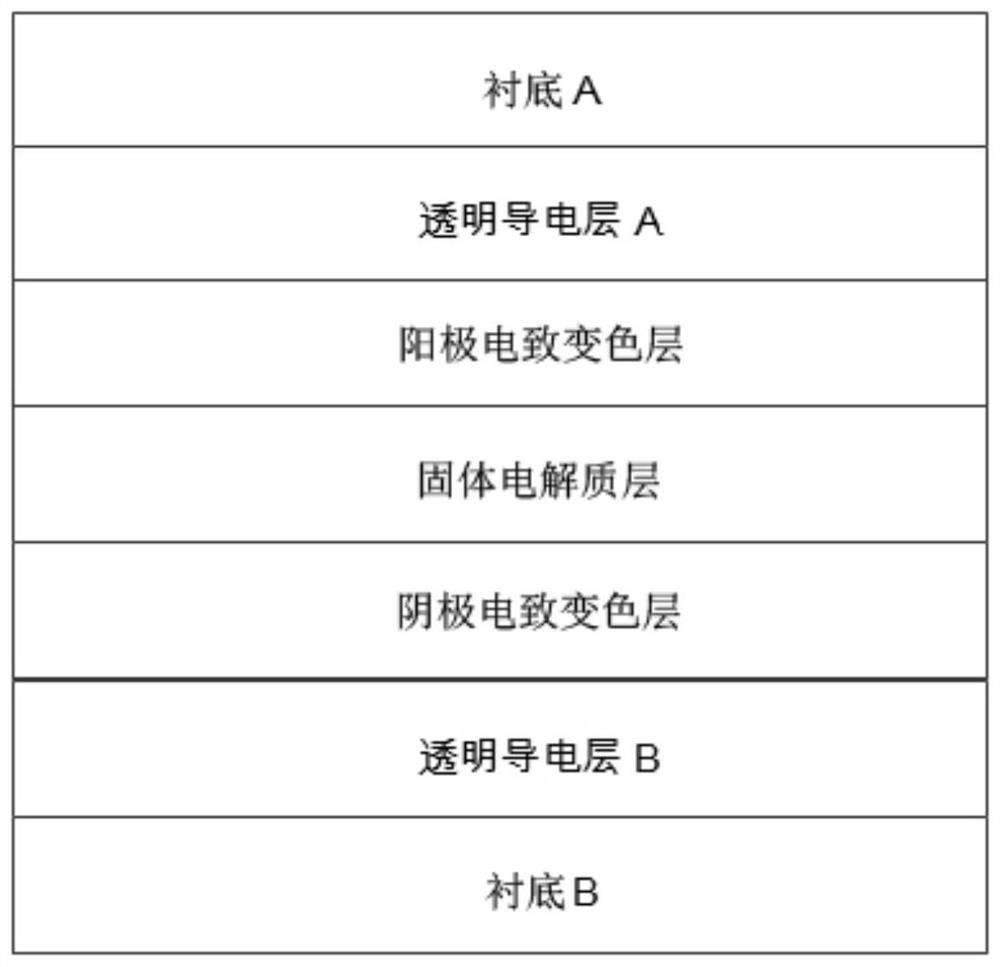

An all-solid-state electrochromic device and its preparation method

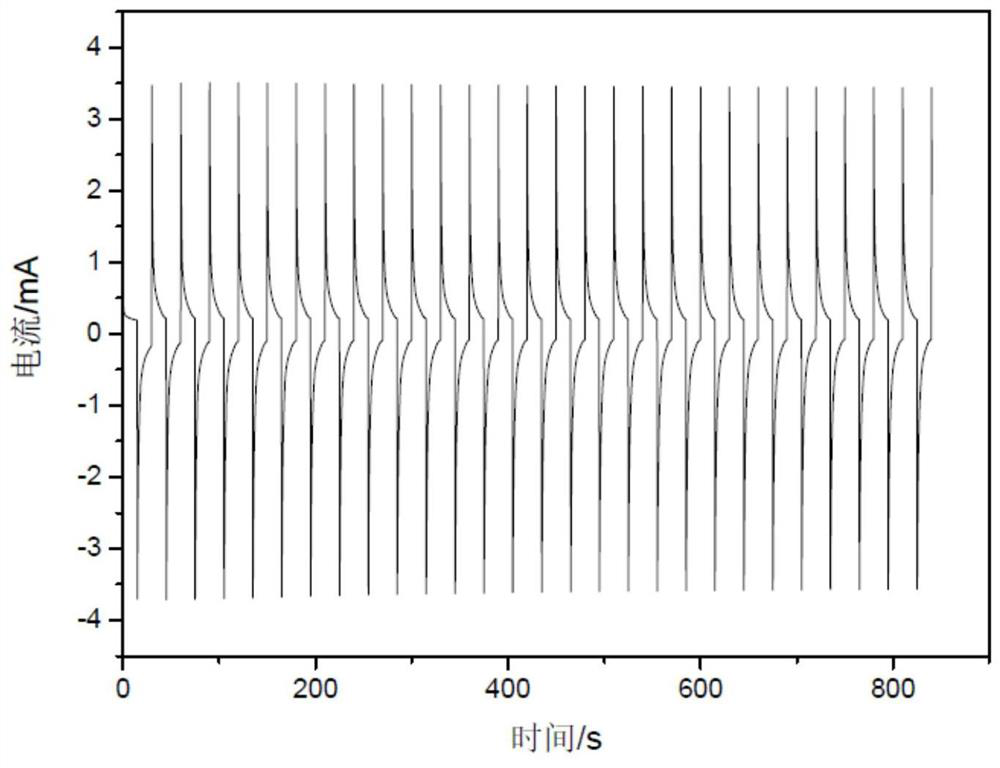

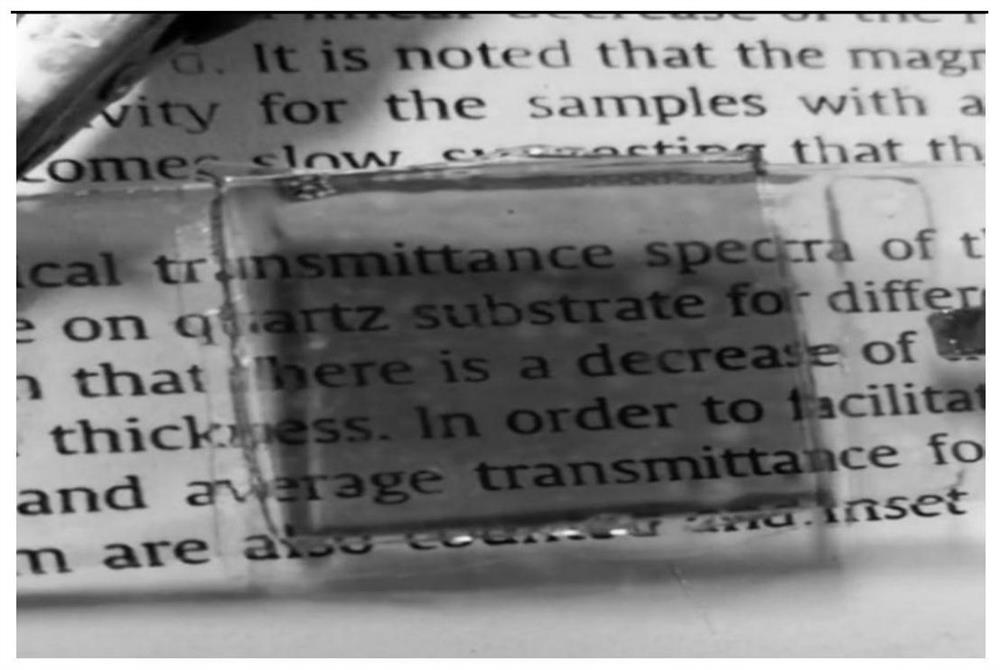

A technology of electrochromic devices and electrochromic layers, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of harsh production conditions, complex sputtering equipment, high production line requirements, etc., and achieve good stability in use, electrochemical The effect of high stability and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing an all-solid-state electrochromic device, comprising the steps of:

[0064] Step 1: Treatment of Substrate A and FTO Glass (2cm×3cm)

[0065] (1) Ultrasonic cleaning treatment: Substrate A and FTO glass (2cm×3cm) with transparent conductive layer A are respectively cleaned with detergent, deionized water, acetone and ethanol in an ultrasonic device for 5 to 10 minutes After that, take it out and dry it with drying equipment;

[0066] (2) Surface active treatment: Substrate A and FTO glass (2cm×3cm) after ultrasonic cleaning are subjected to surface active treatment respectively, and set aside;

[0067] Step 2: Preparation of anodic electrochromic layer

[0068] Weigh 7.145g of nickel nitrate, dissolve it in 125ml of absolute ethanol and stir evenly; weigh 0.65g of lithium acetate, dissolve it in 125ml of absolute ethanol and stir evenly, mix the above two solutions together, stir homogeneous, a clear solution II was obtained;

[0069] Weigh 3....

Embodiment 2

[0087] A method for preparing an all-solid-state electrochromic device, comprising the steps of:

[0088] Step 1: Processing of Substrate A and Substrate B

[0089](1) Ultrasonic cleaning treatment: Substrate A and FTO glass (2cm×3cm) with transparent conductive layer A are respectively cleaned with detergent, deionized water, acetone and ethanol in an ultrasonic device for 5 to 10 minutes After that, take it out and dry it with drying equipment;

[0090] (2) Surface active treatment: Substrate A and FTO glass (2cm×3cm) after ultrasonic cleaning are subjected to surface active treatment respectively, and set aside;

[0091] Step 2: Preparation of anodic electrochromic layer

[0092] Weigh 7.145g of nickel nitrate, dissolve it in 125ml of absolute ethanol and stir evenly; weigh 0.65g of lithium acetate, dissolve it in 125ml of absolute ethanol and stir evenly, mix the above two solutions together, stir homogeneous, a clear solution II was obtained;

[0093] Weigh 3.278g of ...

Embodiment 3

[0111] A method for preparing an all-solid-state electrochromic device, comprising the steps of:

[0112] Step 1: Processing of Substrate A and Substrate B

[0113] (1) Ultrasonic cleaning treatment: Substrate A and FTO glass (2cm×3cm) with transparent conductive layer A are respectively cleaned with detergent, deionized water, acetone and ethanol in an ultrasonic device for 5 to 10 minutes After that, take it out and dry it with drying equipment;

[0114] (2) Surface active treatment: Substrate A and FTO glass (2cm×3cm) after ultrasonic cleaning are subjected to surface active treatment respectively, and set aside;

[0115] Step 2: Preparation of anodic electrochromic layer

[0116] Weigh 7.145g of nickel nitrate, dissolve it in 125ml of absolute ethanol and stir evenly; weigh 0.65g of lithium acetate, dissolve it in 125ml of absolute ethanol and stir evenly, mix the above two solutions together, stir homogeneous, a clear solution II was obtained;

[0117] Weigh 3.278g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com