Method for determining performance of cathode material for lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in material excitation analysis, material electrochemical variables, electrical excitation analysis, etc., can solve the problems of inability to become performance conditions and large result errors, and achieves small errors, high accuracy, and methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for judging the performance of a lithium-ion battery cathode material, comprising the steps of:

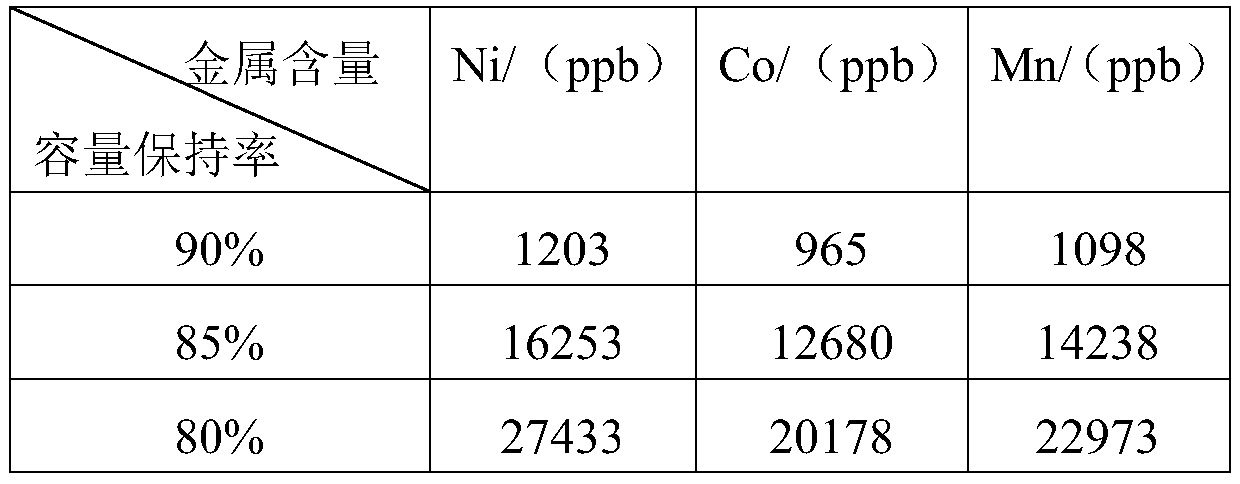

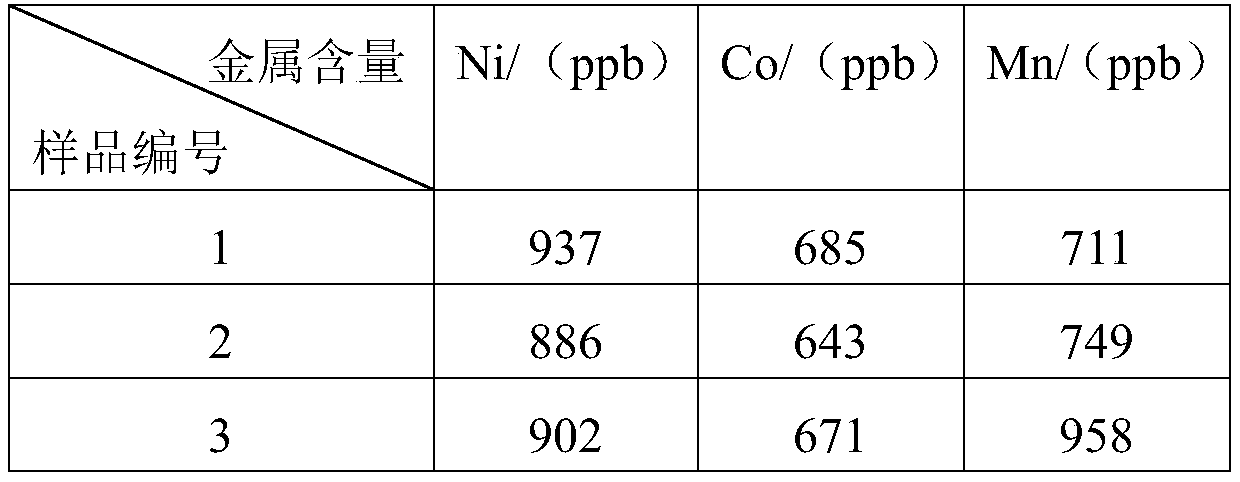

[0030] (a) Take 10g of the ternary positive electrode material of a lithium-ion battery, make it into a button battery, and carry out charge-discharge cycles to the button battery according to the metal dissolution charge-discharge system. After 100 cycles, the button battery is measured. The capacity retention rate is 90%, and then the button battery is disassembled to take out its pole piece;

[0031] (b) Put the electrode piece in a 100mL beaker, and add 10mL dimethyl carbonate to the beaker to infiltrate the electrode piece, then place the beaker in an ultrasonic cleaner for 10 minutes of ultrasonication, and take out the electrode piece after ultrasonication to obtain the infiltration solution , then use quantitative filter paper to filter the infiltration solution into another 100mL beaker, and use 5mL dimethyl carbonate to rinse the filter paper, and the res...

Embodiment 2

[0036] A method for judging the performance of a lithium-ion battery cathode material, comprising the steps of:

[0037] (a) Take 10g of the ternary positive electrode material of a lithium-ion battery, make it into a button battery, and carry out charge-discharge cycles to the button battery according to the metal dissolution charge-discharge system. After 100 cycles, the button battery is measured. The capacity retention rate is 85%, and then the button battery is disassembled to take out its pole piece;

[0038] (b) Put the electrode piece in a 100mL beaker, and add 10mL dimethyl carbonate to the beaker to infiltrate the electrode piece, then place the beaker in an ultrasonic cleaner for 10 minutes of ultrasonication, and take out the electrode piece after ultrasonication to obtain the infiltration solution , then use quantitative filter paper to filter the infiltration solution into another 100mL beaker, and use 5mL dimethyl carbonate to rinse the filter paper, and the res...

Embodiment 3

[0043] A method for judging the performance of a lithium-ion battery cathode material, comprising the steps of:

[0044] (a) Take 10g of the ternary positive electrode material of a lithium-ion battery, make it into a button battery, and carry out charge-discharge cycles to the button battery according to the metal dissolution charge-discharge system. After 100 cycles, the button battery is measured. The capacity retention rate is 80%, and then the button battery is disassembled to take out its pole pieces;

[0045] (b) Put the electrode piece in a 100mL beaker, and add 10mL dimethyl carbonate to the beaker to infiltrate the electrode piece, then place the beaker in an ultrasonic cleaner for 10 minutes of ultrasonication, and take out the electrode piece after ultrasonication to obtain the infiltration solution , then use quantitative filter paper to filter the infiltration solution into another 100mL beaker, and use 5mL dimethyl carbonate to rinse the filter paper, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com