Clothes treatment equipment

A clothing treatment equipment and technology for clothing treatment, which are applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of reduced space, unfavorable installation of heat pump systems, and unfavorable fixing of compressors of heat pump systems, etc. Stability, improve the effect of the installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

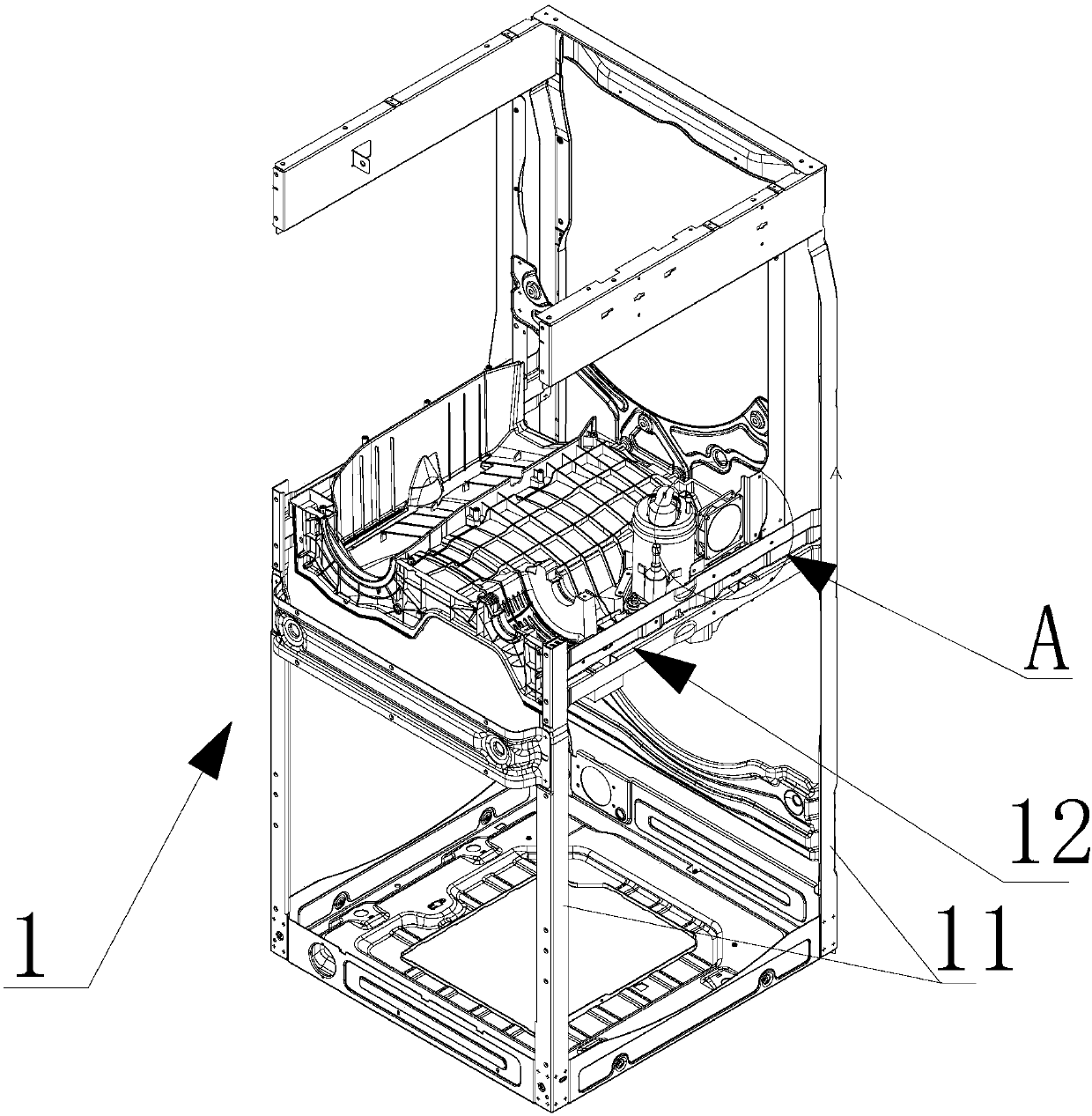

[0049] see Figure 1-Figure 12 As shown, the present embodiment provides a clothes processing device, including a framework 1 and a first clothes treatment cylinder and a second clothes treatment cylinder respectively installed in the framework 1, and also includes a heat pump system and an installation platform 3, and the installation platform 3 is fixed On the frame 1 and between the first laundry processing cylinder and the second laundry processing cylinder, the mounting platform 3 includes a partially raised avoiding portion 31 and a planar mounting portion 32. The heat pump system includes a compressor 2, a compression The machine 2 is fixed on the installation portion 32 of the installation table 3 .

[0050] In the above solution, the installation platform 3 is provided with a protruding avoidance part 31 corresponding to the second clothes processing cylinder at the bottom thereof. The design of the avoidance part 31 is not conducive to the installation and fixation o...

Embodiment 2

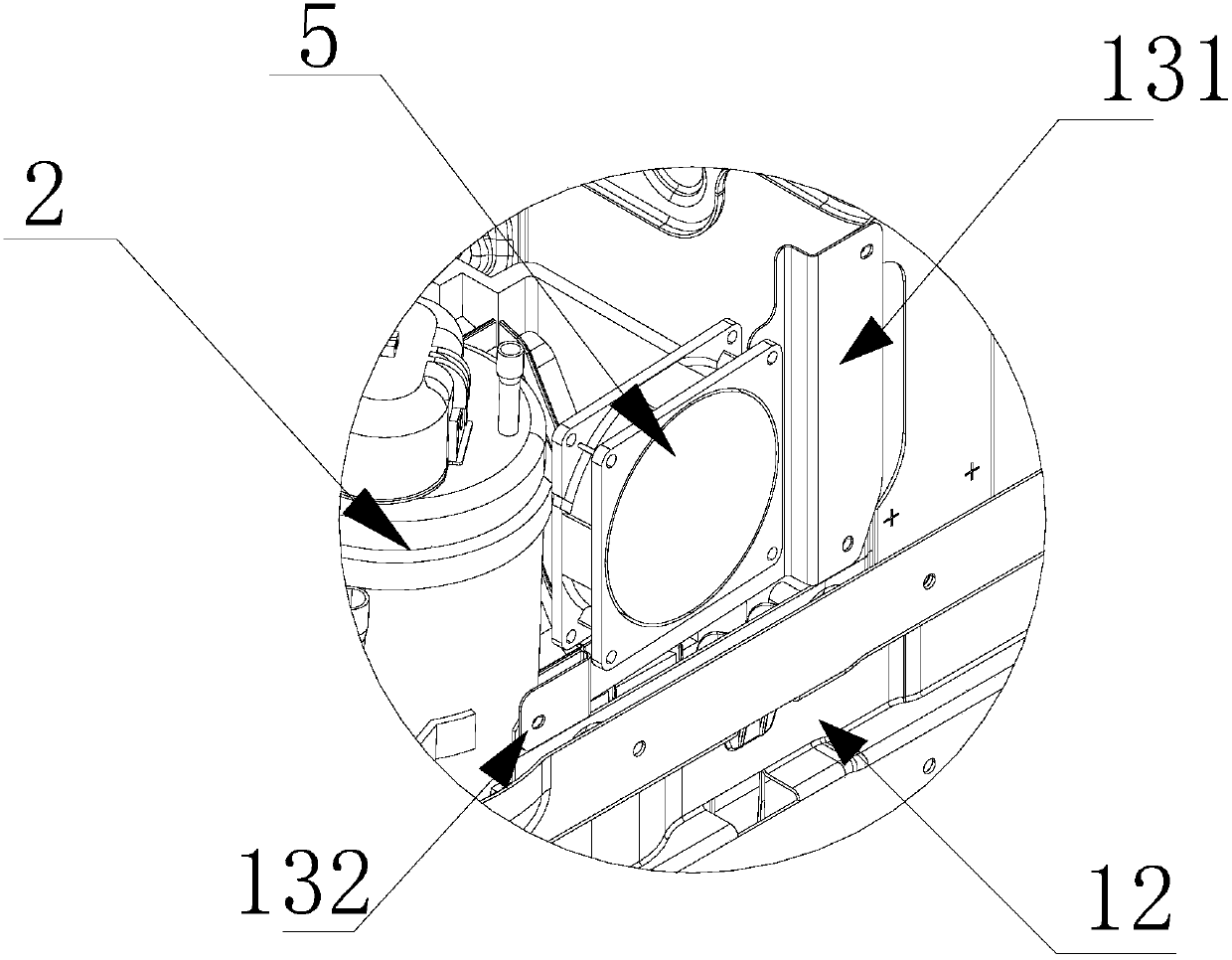

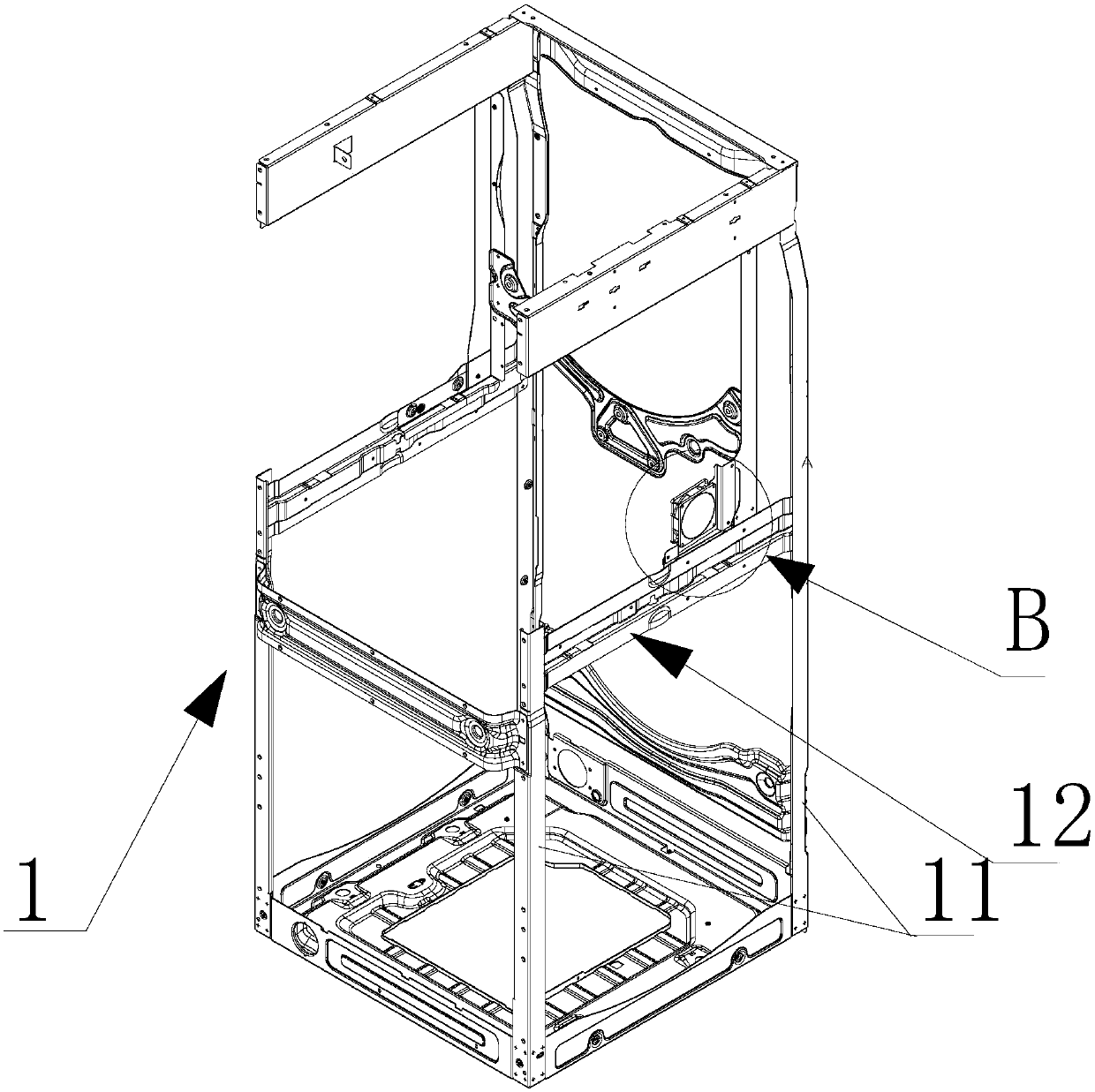

[0068] see Figure 1-Figure 12 As shown, the second embodiment describes the laundry treatment equipment of the present invention from another perspective, the laundry treatment equipment also includes a heat pump system, a frame 1 and an installation platform 3 installed on the frame 1, and the heat pump system includes a compressor 2 and a cooling fan 5 , the compressor 2 is installed on the installation platform 3 , and the cooling fan 5 is fixed on the framework 1 and arranged opposite to the compressor 2 .

[0069] In the above scheme, considering the small problem of the internal space of the mounting table 3, the cooling fan 5 is fixed on the frame 1, thereby saving the installation space on the mounting table 3, and the cooling fan 5 is fixed on the frame 1, cooling The fan 5 is closer to the casing of the clothes processing device, which improves the ventilation effect and is beneficial to cooling the compressor 2 .

[0070] Preferably, the framework 1 includes a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com