Removal of organic pollutants in wastewater based on rattle-shaped nanocomposites

A technology of nanocomposite materials and organic pollutants, applied in water pollutants, organic compound/hydride/coordination complex catalysts, water/sewage treatment, etc., can solve the problem of reducing catalytic active sites, affecting catalytic activity, Enrichment pollutants limit and other issues, to achieve the effect of environmental protection, fast and efficient removal, and shorten the degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

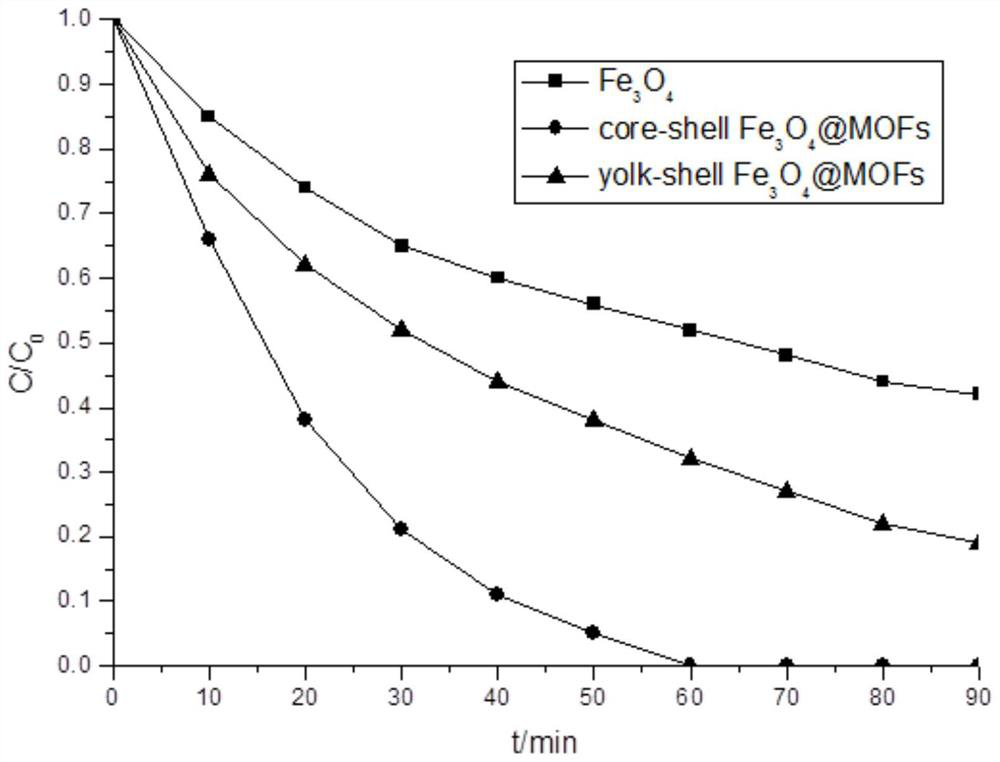

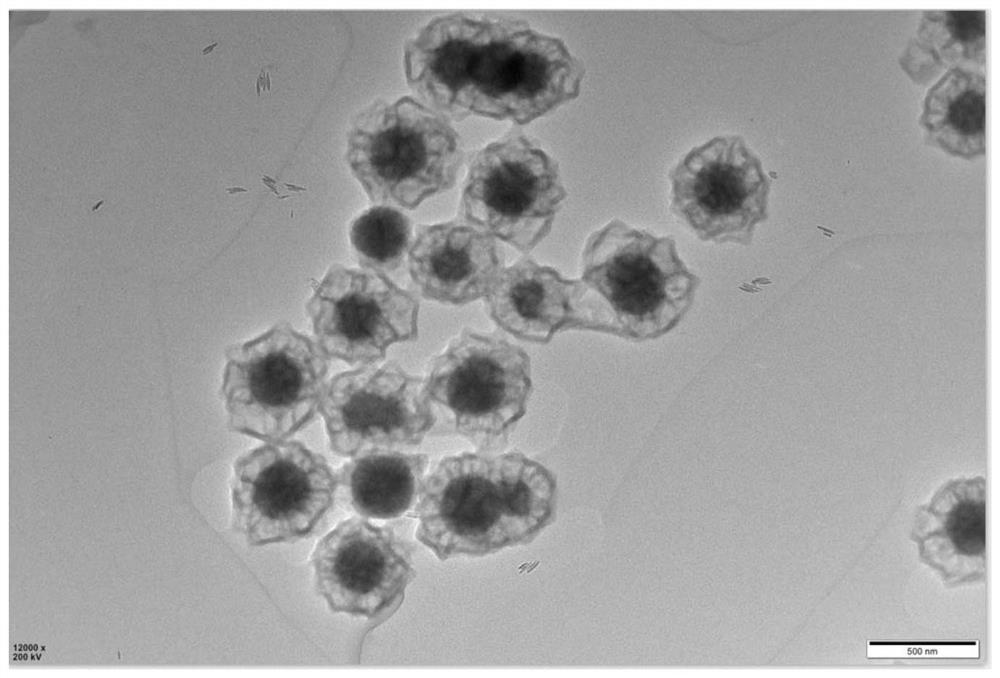

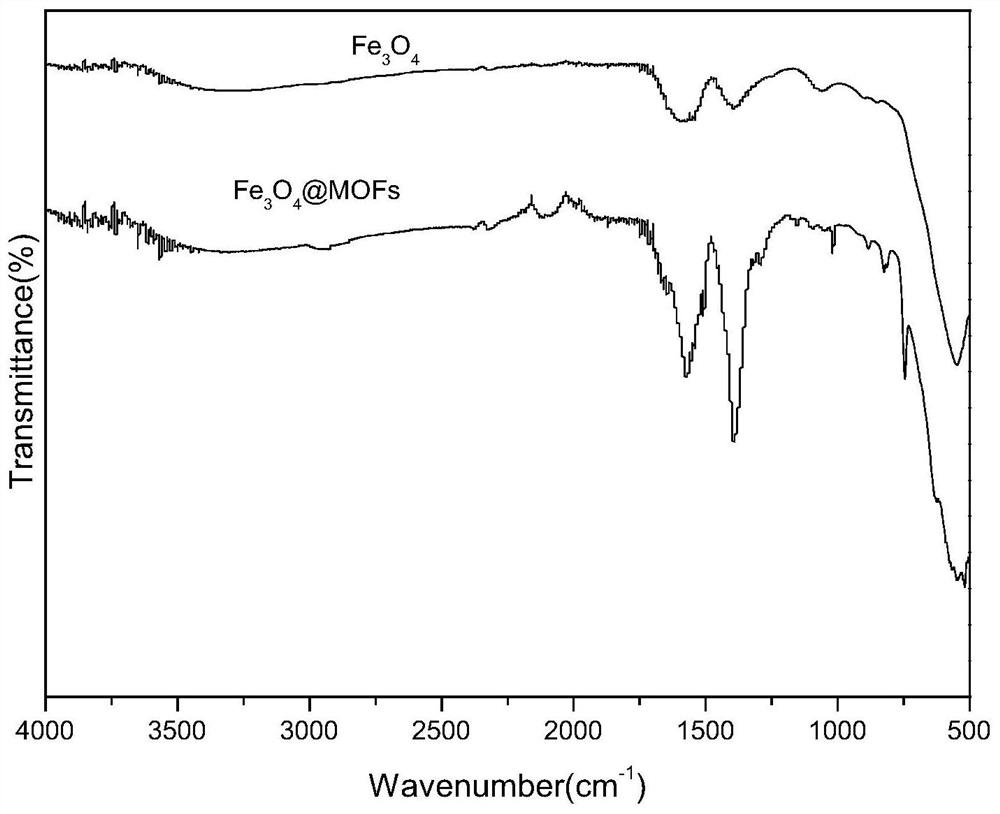

[0030] Such as Figure 1-6 Shown, a method for removing organic pollutants in wastewater based on rattle-type nanocomposites comprises the following steps:

[0031] (1), first add 0.1M hydrochloric acid to the wastewater whose methylene blue concentration is 50mg / L, adjust the initial pH value of the wastewater to 4, and then add Fe in an amount of 1.0g / L 3 o 4 The @MOFs nanocomposite material was added to the wastewater, and after stirring for 5 minutes, the addition of 30mM H 2 o 2 Add, continue to stir, control the reaction temperature to 35°C, and the reaction time to 60min;

[0032] (2), said step (1) after the completion of the reaction to form a mixed solution A, then using an external magnetic field will Fe 3 o 4 The @MOFs nanocomposite was separated from the mixed solution A, and the pH of the separated liquid was adjusted to neutral before discharge.

[0033] Rattle Fe 3 o 4 The preparation steps of @MOFs nanocomposites are as follows:

[0034] (1), weighing...

Embodiment 2

[0040] Such as Figure 1-6 Shown, a method for removing organic pollutants in wastewater based on rattle-type nanocomposites comprises the following steps:

[0041] (1), first add 0.1M hydrochloric acid to the wastewater with a phenol concentration of 30mg / L, adjust the initial pH value of the wastewater to 3, and then add 0.8g / L of Fe 3 o 4 The @MOFs nanocomposite material was added to the wastewater, and after stirring for 3 minutes, 25mM H 2 o 2 Add, continue to stir, control the reaction temperature to 25°C, and the reaction time to 30min;

[0042] (2), said step (1) after the completion of the reaction to form a mixed solution A, then using an external magnetic field will Fe 3 o 4 The @MOFs nanocomposite was separated from the mixed solution A, and the pH of the separated liquid was adjusted to neutral before discharge.

[0043] Rattle Fe 3 o 4 The preparation steps of @MOFs nanocomposites are as follows:

[0044] (1), weighing: take by weighing 35mg, particle di...

Embodiment 3

[0050] Such as Figure 1-6 Shown, a method for removing organic pollutants in wastewater based on rattle-type nanocomposites comprises the following steps:

[0051] (1), first add 0.1M hydrochloric acid to the wastewater with a rhodamine B concentration of 100mg / L, adjust the initial pH value of the wastewater to 4, and then add Fe in an amount of 1.2g / L 3 o 4 The @MOFs nanocomposite material was added to the wastewater, and after stirring for 5 minutes, the addition of 35mM H 2 o 2 Add, continue to stir, control the reaction temperature to 45°C, and the reaction time to 90min;

[0052] (2), said step (1) after the completion of the reaction to form a mixed solution A, then using an external magnetic field will Fe 3 o 4 The @MOFs nanocomposite was separated from the mixed solution A, and the p H is adjusted to neutral and then discharged.

[0053] Rattle Fe 3 o 4 The preparation steps of @MOFs nanocomposites are as follows:

[0054] (1), weighing: weigh 50m g , a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com