Strong wet friction resistant thermosensitive film and manufacturing method thereof

A manufacturing method and wet rubbing technology, applied in the directions of copying/marking methods, printing, etc., can solve the problems of hydrophilicity affecting wet friction resistance, film layer cross-linking degree is not very good, affecting product printing performance, etc., to achieve excellent use. value, good printing requirements, the effect of improving the protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

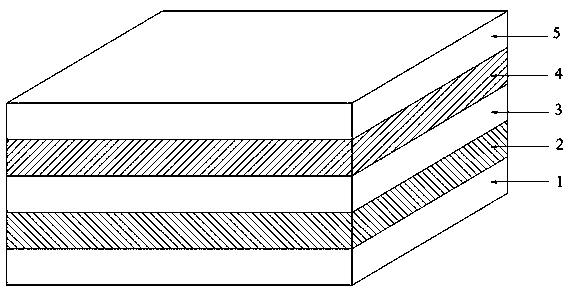

[0033] A heat-sensitive film resistant to strong wet friction, such as figure 1 As shown, it includes a base film 1 , a primer layer 2 , a heat-sensitive layer 3 , a water-resistant layer 4 and a print adaptation layer 5 from bottom to top. Wherein, the base film is a glossy-matte or double-sided glossy or double-sided matte BOPP original film; the primer layer 2 is coated with acrylic resin or a mixture of acrylic resin and hollow spherical plastic pigments. ; The heat-sensitive layer 3 is coated with a coating containing acrylic resin and / or modified polyvinyl alcohol; the water-resistant layer 4 is coated with a water-based UV coating; the print adaptation layer 5 is coated with a component containing Zinc stearate lubricant, water-washed kaolin, water-based acrylic resin, modified polyvinyl alcohol and cross-linking agent are coated. And the solid content of acrylic resin in the primer layer 2 accounts for more than 50% of the total solid content of the layer; the solid c...

Embodiment 2

[0034] Embodiment 2: prepare primer coating

[0035]First, weigh the components of the primer coating in the following parts by weight, hollow ball: 30-45 parts, acrylic resin emulsion: 50-65 parts, calcium stearate lubricant: 3-5 parts, defoamer: 1-5 parts 2 servings. Then, add hollow balls into the preparation tank, start stirring, then add water-based acrylic resin emulsion, calcium stearate lubricant and defoamer, stir for 40 minutes at a speed of 100-150 rpm, measure the solid content of the coating, and form a primer Cloth liquid, set aside.

Embodiment 3

[0036] Embodiment 3: preparation of inorganic pigment dispersion liquid

[0037] First, weigh the components of the inorganic pigment dispersion liquid in the following parts by weight: inorganic dispersant: 1-2 parts, polyether defoamer: 0.3-0.5 parts, light calcium carbonate: 98-99 parts. Then, add water to the dispersion tank, start stirring, add inorganic dispersant, defoamer, and light calcium carbonate, disperse at high speed for 60 minutes, and form a pigment dispersion liquid for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com